When purchasing بطانات كربيد التنغستن, precision is paramount. Tungsten carbide is known for its high مقاومة التآكل, durability, and strength, which make it ideal for harsh industrial environments.

However, ensuring that the right tolerances are specified in a Request for Quotation (RFQ) is key to receiving a high-quality product that meets your exact requirements.

In this article, we will explore the essential tolerances to include in RFQs for tungsten carbide bushings to ensure a perfect fit and optimal performance.

Why Tolerances Matter in Tungsten Carbide Bushings

Tolerances define the acceptable limits of variation in dimensions, allowing for proper fit and function in the application. The correct tolerances are crucial for several reasons:

Ensure Proper Fit: Accurate tolerances ensure the bushing fits precisely with the shaft or housing, preventing issues like misalignment or wear.

Optimize Performance: Tight tolerances ensure the bushing performs as expected, preventing early failure or excessive wear.

Quality Assurance: Including the right tolerances in your RFQ ensures the manufacturer knows your requirements and can meet your specifications.

Without proper tolerances, you may encounter issues such as poor sealing, excessive friction, and damage to the bushing or other components.

Key Tolerances to Include in an RFQ for Tungsten Carbide Bushings

When specifying tungsten carbide bushings in your RFQ, it’s important to include the following key tolerances:

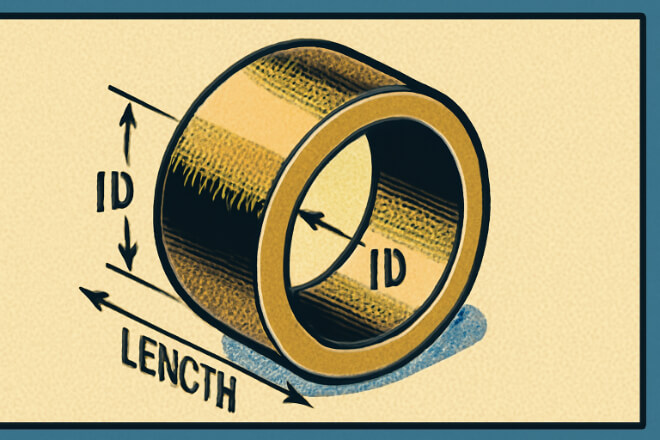

1). Inner Diameter (ID) Tolerance

The inner diameter tolerance ensures the bushing fits correctly around the shaft. The most common tolerances for ID are:

General Tolerance: ±0.005 mm to ±0.01 mm

Fine Tolerance: ±0.001 mm to ±0.003 mm

A tight ID tolerance is essential for ensuring a proper press fit and preventing clearance issues.

2). Outer Diameter (OD) Tolerance

The outer diameter tolerance controls how well the bushing fits within its housing. Common tolerances for OD include:

General Tolerance: ±0.01 mm to ±0.02 mm

Fine Tolerance: ±0.005 mm to ±0.01 mm

This ensures that the bushing can be easily installed while maintaining a secure fit to avoid issues such as movement or vibration.

3). Length Tolerance

Length tolerance is important for ensuring the bushing fits within the designated space. Common tolerances for length are:

Standard Tolerance: ±0.02 mm to ±0.05 mm

Precise Tolerance: ±0.01 mm

Too much variation in length can result in misalignment or improper function of the bushing.

4). Roundness (Concentricity) Tolerance

Roundness tolerance ensures that the bushing remains round throughout its entire circumference, preventing it from wearing unevenly or causing vibrations. Common tolerances for roundness are:

General Tolerance: 0.01 mm to 0.02 mm

Fine Tolerance: 0.005 mm to 0.01 mm

Poor roundness can lead to premature failure of the bushing or damage to other components.

5). Surface Finish Tolerance (Ra Value)

Surface finish tolerance ensures that the bushing’s surface is smooth enough to reduce friction and prevent wear.

This tolerance is often measured in Ra (Roughness Average). For tungsten carbide bushings, typical Ra values are:

Standard Finish: Ra ≤ 0.2 µm

Mirror Finish: Ra ≤ 0.05 µm

A smoother surface reduces the risk of wear and tear, and helps the bushing perform more effectively over time.

6). Tolerance for Material Composition

Material composition tolerances are critical for ensuring the bushing performs as expected.

Ensure that the part’s binder content (such as WC-Co or WC-Ni) falls within the required percentage range. This can influence the bushing’s hardness, toughness, and wear resistance.

How Tight Tolerances Impact Cost and Lead Time

Including tighter tolerances in your RFQ typically results in higher manufacturing costs and longer lead times. Here’s why:

Manufacturing Complexity: Tight tolerances require more precise machining and additional steps to ensure the part meets the specifications.

Increased Quality Control: Stricter tolerances necessitate additional inspections and testing, which can extend production time and increase costs.

Material Waste: Achieving tighter tolerances can lead to higher material waste, as more parts may be rejected during the production process.

If the application doesn’t require extremely tight tolerances, opting for a more standard specification can help reduce costs and lead time without sacrificing performance.

Communicating Tolerances Clearly in Your RFQ

When submitting your RFQ, it’s important to communicate tolerances clearly to ensure the manufacturer understands your requirements. Here are some tips to help you specify tolerances effectively:

Use Standard Tolerance Codes: Refer to standard tolerance codes such as those found in ISO 2768 or ASME Y14.5 to ensure clarity and consistency.

Specify Tolerance Classes: If applicable, specify tolerance classes (e.g., “H7” for hole tolerances or “k6” for shaft tolerances) to provide additional details.

Include Additional Specifications: If you have specific performance or durability requirements, be sure to include these in your RFQ as well.

Clear communication of tolerances helps avoid misunderstandings and ensures that you receive a bushing that meets your needs.

Best Practices for Reviewing Tolerances in Received Bushing Samples

Once you receive your بطانات كربيد التنغستن, it’s essential to verify that the tolerances are met before proceeding with mass production. Here are some best practices for reviewing received samples:

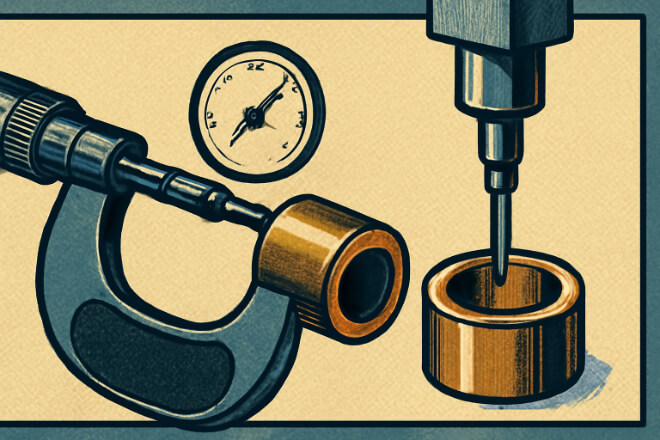

Use Precision Measurement Tools: Use tools such as calipers, micrometers, and CMM (Coordinate Measuring Machines) to measure the bushing’s dimensions accurately.

Perform Roundness and Surface Finish Tests: Check the roundness and surface finish using appropriate testing methods to ensure compliance with the specified tolerances.

Cross-Check with Specifications: Compare the measured values against the specifications outlined in the RFQ to ensure they meet your requirements.

By reviewing the samples thoroughly, you can catch potential issues early and avoid costly mistakes during production.

خاتمة

Specifying the correct tolerances for tungsten carbide bushings in your RFQ is essential for ensuring optimal performance and fit.

By understanding key tolerances such as ID, OD, length, roundness, and surface finish, you can ensure the bushing meets your application requirements.

While tighter tolerances may improve precision, they also increase cost and lead time, so it’s important to balance performance needs with budget and timeline constraints.

Clear communication of your tolerances to the manufacturer will ensure a smooth production process and high-quality results.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.