Tungsten carbide tips are highly durable and used in demanding industrial applications such as cutting, drilling, and machining.

However, even the toughest materials require regular maintenance to ensure they continue performing at their best.

Proper maintenance can significantly extend the lifespan of tungsten carbide tips, improve efficiency, and reduce downtime in production.

This blog will explore why regular maintenance is essential for tungsten carbide tips and provide best practices for maintaining these valuable tools.

Why Regular Maintenance is Crucial for Tungsten Carbide Tips

Tungsten carbide is known for its صلابة و مقاومة التآكل, but it is still prone to damage from wear, impact, and thermal shock over time.

Without proper maintenance, tools can lose their sharpness, experience increased wear, or fail prematurely. Regular maintenance helps to:

Extend Tool Life: By addressing minor issues early, you prevent more serious damage that could lead to tool failure.

Maintain Cutting Performance: Regular inspection and sharpening keep the tips performing efficiently, ensuring that your tools continue to meet quality standards.

Avoid Downtime: Routine maintenance minimizes the risk of unexpected tool failure, reducing downtime in production processes.

Optimize Cost Efficiency: Prolonging the life of tungsten carbide tips lowers the frequency of replacements and improves overall productivity.

Types of Maintenance for Tungsten Carbide Tips

Different types of maintenance practices are essential to keeping tungsten carbide tips in top condition.

These practices focus on preventing wear, checking for damage, and restoring cutting efficiency.

1). Inspection and Cleaning

Regularly inspecting and cleaning tungsten carbide tips helps identify early signs of wear, cracks, or other damage. During inspections, technicians should check for:

Cracks or chips on the cutting edge

Signs of wear or dullness

Surface damage from thermal shock or impact

Cleaning tips to remove debris and buildup is equally important. Accumulated materials can cause additional wear or affect the tool’s performance.

Using the right cleaning agents and techniques ensures that the tips stay in good condition.

2). Sharpening

Sharpening tungsten carbide tips is essential to maintain their cutting performance. Over time, the tips may become dull due to constant use.

A properly sharpened tip ensures more precise cutting, reducing the strain on machines and increasing efficiency.

However, sharpening should be done carefully, as excessive sharpening can weaken the tip. Specialized grinding wheels or machines should be used to preserve the integrity of the carbide.

3). Re-coating

Tungsten carbide tips may be coated with materials like titanium nitride (TiN) or diamond-like carbon (DLC) to enhance their مقاومة التآكل.

Over time, coatings may wear away, especially in high-stress applications. Re-coating tips periodically helps maintain their protective layer and prevents premature wear.

4). Replacing Damaged Tips

In some cases, regular maintenance may not be enough to restore the tip’s performance.

If cracks, chips, or significant wear are found during inspections, replacing the tip is the best option.

Replacing a damaged tip prevents the risk of further damage to the equipment and ensures that production quality remains consistent.

The Role of Proper Handling in Maintaining Tungsten Carbide Tips

Proper handling is a critical part of maintenance. Tungsten carbide tips, while durable, are still susceptible to damage from improper handling.

Here are some key handling tips to prevent unnecessary wear and breakage:

Avoid Dropping: Tungsten carbide is brittle, and dropping tips onto hard surfaces can cause cracks or chips.

Use Proper Tools: When installing or adjusting carbide tips, use soft hammers or rubber mallets to avoid impacting the tips directly with metal tools.

Store Correctly: When not in use, store tungsten carbide tips in protective cases or trays to prevent them from being exposed to shocks or contact with hard surfaces.

Optimal Cutting Parameters for Tungsten Carbide Tips

Maintaining tungsten carbide tips also involves ensuring that the cutting parameters are optimized.

Using the wrong settings can cause excessive wear or thermal shock, which can damage the tips. Key factors to consider include:

سرعة القطع: Ensure that the cutting speed is appropriate for the material being worked on. Too high of a speed can overheat the tip, while too low of a speed can cause excessive friction.

Feed Rate: Adjust the feed rate to match the material صلابة. A high feed rate can increase the wear on the tip.

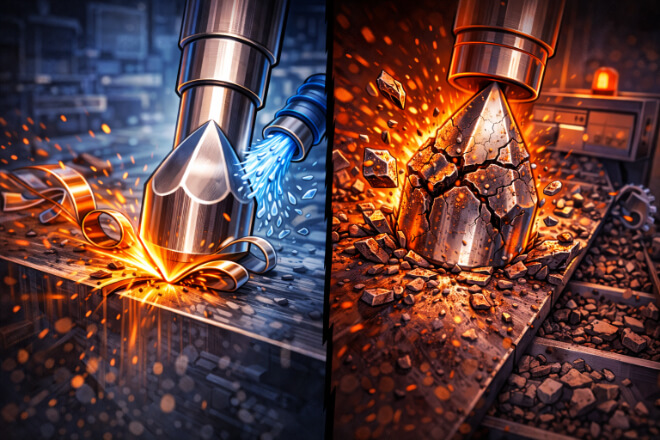

Coolant Use: Proper cooling helps to dissipate heat and prevent thermal shock. Ensure that the correct amount and type of coolant is used during the cutting process.

Using optimal cutting parameters helps reduce wear and prolongs the lifespan of tungsten carbide tips.

How Often Should Tungsten Carbide Tips Be Maintained?

The frequency of maintenance depends on the specific application and the amount of use the tungsten carbide tips experience. However, as a general rule:

Inspection and Cleaning: Should be done regularly, ideally after each use or at least weekly in high-demand applications.

شحذ: Perform sharpening as needed, typically after every few uses depending on the material being cut.

Re-coating: Check the coating after every few months of use, especially in high-stress environments.

Replacing Tips: Replace tips when visible damage such as cracks, chips, or excessive wear is found during inspections.

Establishing a maintenance schedule based on your specific application will help ensure that your tungsten carbide tips remain in good condition.

خاتمة

Regular maintenance is essential to ensuring that tungsten carbide tips continue to perform at their best.

By incorporating inspection, cleaning, sharpening, re-coating, and proper handling, companies can extend the lifespan of their tools, improve cutting performance, and avoid costly downtime.

Understanding the importance of regular maintenance helps companies optimize productivity and cost-efficiency in industries that rely on high-performance tools.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.