Tungsten carbide tips are widely used in industrial applications for their صلابة والمتانة.

However, even the toughest tools can break or fail under certain conditions. Understanding why tungsten carbide tips break is crucial for improving tool performance and reducing downtime.

In this article, we will explore the common causes of tungsten carbide tip failure and provide practical solutions to prevent breakage, ensuring better tool longevity and reduced operational costs.

Impact and Shock Loads

One of the most common causes of tungsten carbide tip breakage is exposure to excessive impact or shock loads. Tungsten carbide is extremely hard but can be brittle under sudden or excessive stress.

تأثير ثقيل: When tungsten carbide tips encounter sudden impacts, such as hard material or misaligned machinery, the tips can crack or break.

Shock Loads: When the cutting force is applied unevenly or too forcefully, the carbide can fracture, especially if it’s used in applications where the material is inconsistent or hard.

To prevent impact-related breakage, ensure that the cutting process is stable, and avoid using the tips on materials that exceed their strength capacity.

Additionally, make sure the machine is aligned properly to prevent uneven forces on the tool.

Overloading and Excessive Pressure

Excessive load or pressure during cutting operations can lead to breakage of tungsten carbide tips.

When the tip is subjected to more force than it is designed to handle, it can lead to cracking, chipping, or even total failure.

Overloading: If the cutting or drilling operation exceeds the recommended pressure or force, the carbide tip may crack due to the high stress.

Improper Machine Settings: Incorrect speed, feed rate, or depth of cut can also cause overloading, which in turn increases the risk of breakage.

To solve this issue, always ensure that the machinery is set according to the manufacturer’s specifications.

Avoid excessive pressure and always use carbide tips that are designed for the material and job at hand.

Improper Handling and Storage

Improper handling and storage are often overlooked causes of tungsten carbide tip breakage.

When carbide tips are mishandled, dropped, or stored incorrectly, they are prone to cracks or chips that can lead to eventual failure.

Dropping or Bumping:

Tungsten carbide tips can break when dropped or knocked against hard surfaces, even if the tool is not in use.

Poor Storage Conditions:

Storing carbide tips in damp or dirty environments can cause corrosion, weakening the material over time.

Storing tips loosely or without proper protection can also lead to physical damage.

To prevent breakage, ensure that carbide tips are stored in protective cases or cushioned trays.

Handle them carefully to avoid drops or knocks, and store them in dry, clean conditions.

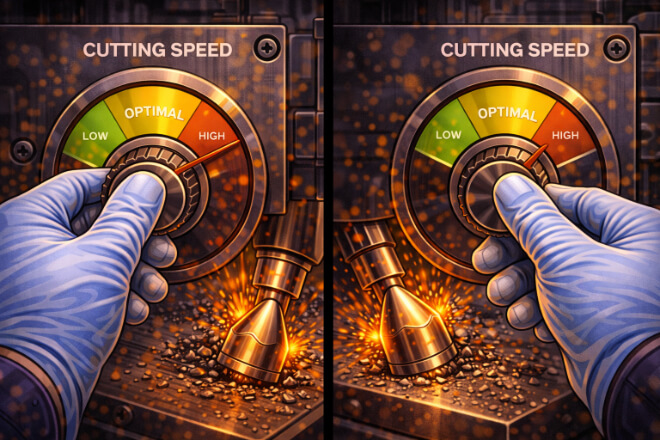

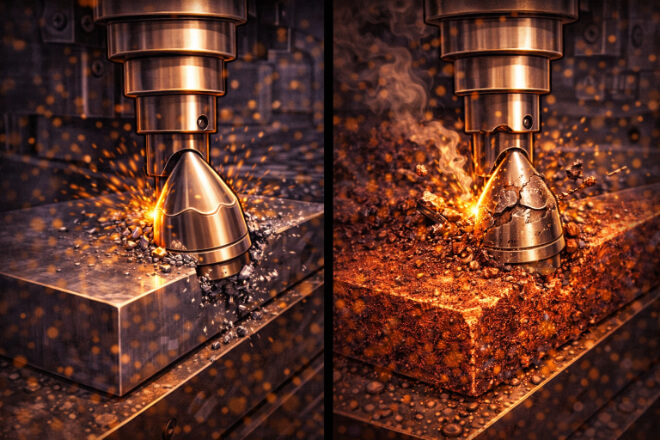

High Cutting Speeds and Heat Build-Up

Excessive heat generated by high cutting speeds can cause tungsten carbide tips to weaken and break.

While carbide is known for its صلابة, it is also prone to thermal damage when exposed to extreme temperatures.

Heat Generation:

If the cutting speed is too high, friction between the carbide tip and the material being cut will generate excessive heat.

This heat can soften the carbide, causing it to become brittle and more likely to break.

Thermal Shock:

Sudden temperature changes, such as moving from a hot cutting environment to a cooler one, can cause the carbide to fracture due to thermal shock.

To prevent breakage from high heat, always monitor the cutting speed to keep it within the recommended range.

Also, ensure proper coolant application to dissipate heat during cutting and prevent overheating.

Material Hardness and Compatibility Issues

While tungsten carbide is hard and مقاوم للتآكل, it can still be vulnerable to breakage when used on materials that are too hard or incompatible with the tool.

Cutting Hard Materials: Using tungsten carbide tips on materials harder than the carbide itself, such as certain alloys or ceramics, can lead to cracking or chipping.

Material Incompatibility: If the material being cut is highly abrasive or uneven, it can cause excessive wear and tear on the tips, leading to failure.

To avoid these issues, always match the صلابة of the material with the appropriate tungsten carbide grade.

Use coatings or specially designed carbide tips for extremely hard or abrasive materials to reduce the risk of breakage.

Wear and Fatigue Over Time

Even the most durable tungsten carbide tips will eventually wear out, especially under harsh and prolonged use.

Over time, repeated cutting cycles can cause the tips to lose their sharpness, leading to increased pressure on the tool, and eventually causing it to break.

Fatigue: Repeated stress from frequent use causes material fatigue, weakening the carbide tip and making it more prone to breaking.

Wear on the Cutting Edge: As the cutting edge wears down, it increases the load on the tip, which can lead to fractures or chips.

To address wear and fatigue, regular maintenance is crucial. Sharpen the tips as needed, and replace them before they become too worn out to perform effectively.

Implementing a regular inspection schedule will help detect wear and prevent breakage from overuse.

خاتمة

Tungsten carbide tips are tough and durable tools, but they are not immune to breaking under certain conditions.

Understanding the common causes of breakage—such as impact loads, overloading, improper handling, high heat, material incompatibility, and wear—can help you take preventive measures to ensure longer tool life and optimal performance.

By addressing these issues early, you can save costs on replacements, improve production efficiency, and keep your operations running smoothly.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.