When it comes to tungsten carbide tips used in cutting tools, their durability and مقاومة التآكل are essential to maintaining high-performance standards. These properties determine how long the tool lasts, how efficiently it cuts, and how much maintenance it requires.

One of the most significant factors influencing these properties is grain size. حجم الحبوب control during the manufacturing process plays a crucial role in optimizing the performance of tungsten carbide tips.

In this blog, we will explore how grain size affects the durability and wear resistance of tungsten carbide tips and why it is essential for industries that rely on high-quality cutting tools.

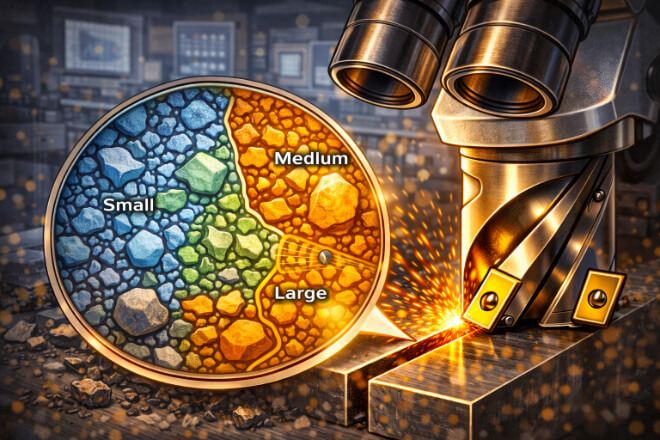

1. What Is Grain Size in Tungsten Carbide Tips?

Grain size refers to the size of the individual particles that make up the tungsten carbide material.

Tungsten carbide is a composite made of tungsten and carbon, and its strength and performance depend on how finely the grains are arranged.

The size of these grains can be controlled during the manufacturing process, and it has a direct impact on the material’s properties.

How حجم الحبوب Affects Tungsten Carbide:

Smaller Grains: Smaller grain sizes tend to result in a more uniform and dense structure, which improves hardness but can reduce toughness.

Larger Grains: Larger grains tend to improve صلابة, making the material more resistant to impact and cracking, but can reduce hardness.

Finding the right balance in grain size is crucial for optimizing the overall performance of the tool.

2. The Relationship Between Grain Size and Durability

Durability refers to how long a cutting tool can function effectively before it begins to degrade. This is directly influenced by the toughness and hardness of the material.

How Grain Size Influences Durability:

- Smaller حجم الحبوب:

Tools with smaller grains are generally harder and more wear-resistant.

This makes them ideal for applications where the tool must endure continuous abrasive wear, such as cutting metals or hard materials.

Larger Grain Size:

Larger grains provide greater صلابة, which is essential when tools are subjected to impact or shock loads, such as in mining or heavy construction applications.

In short, fine-tuning the grain size during manufacturing allows manufacturers to optimize the balance between hardness and toughness to enhance tool durability.

3. How Grain Size Affects Wear Resistance in Tungsten Carbide Tips

Wear resistance is a critical factor in determining how long a tungsten carbide tip lasts under heavy use.

Cutting tools are constantly exposed to high friction, which leads to wear over time.

Controlling the grain size is one of the most effective ways to improve wear resistance.

Effects of حجم الحبوب على مقاومة التآكل:

Fine-Grain Tungsten Carbide:

Fine-grain carbide offers better wear resistance by providing a dense, uniform structure that can withstand the abrasiveness of hard materials.

This makes it ideal for cutting tools used in precision operations, such as milling, drilling, and machining.

Coarse-Grain Tungsten Carbide:

Coarse-grain carbide, while not as wear-resistant as fine-grain carbide, offers superior toughness, which makes it suitable for tools used in heavy-duty applications, such as rock drilling and mining.

The right grain size ensures that the tungsten carbide tip can resist wear while maintaining its cutting ability over extended periods.

4. Balancing Hardness and Toughness Through Grain Size Control

The key challenge in designing tungsten carbide tips is balancing hardness and toughness.

While hardness helps resist wear, toughness ensures that the material doesn’t crack or break under stress.

By controlling the حجم الحبوب, manufacturers can strike the right balance between these two properties.

Optimizing Hardness and Toughness:

Smaller Grains for صلابة: When the grain size is reduced, the tungsten carbide becomes harder, making it more resistant to wear but more susceptible to impact damage.

Larger Grains for صلابة: Larger grains enhance the material’s toughness, making it less likely to fracture but reducing its ability to resist wear.

By carefully controlling the grain size, manufacturers can design tungsten carbide tips that offer the best balance of hardness and toughness for specific applications.

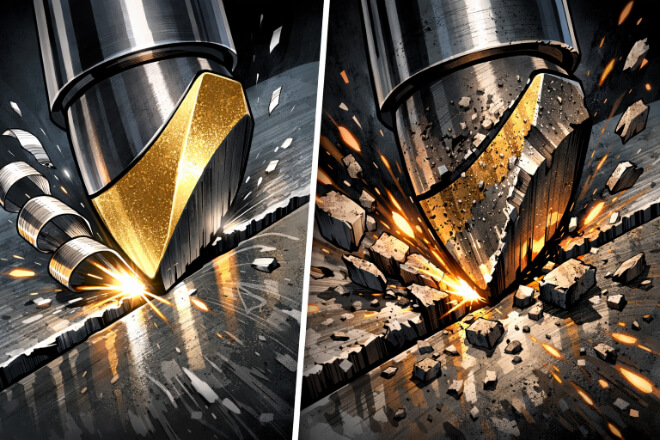

5. The Impact of Grain Size on Cutting Performance

Cutting performance is closely tied to both the hardness and toughness of the cutting tool.

Tools with the right grain size can improve cutting efficiency by maintaining sharpness for longer and reducing the frequency of tool changes.

How حجم الحبوب Affects Cutting Performance:

Fine-Grain Tungsten Carbide: Ideal for applications requiring high precision and fast cutting speeds, fine-grain carbide offers excellent edge retention and smooth cutting performance.

Coarse-Grain Tungsten Carbide: Best for applications that require strength and stability under heavy stress or impact, such as rough cutting and heavy-duty drilling.

The grain size affects how quickly the tool wears down and how efficiently it performs over time. Optimizing grain size can help maximize cutting performance while minimizing downtime.

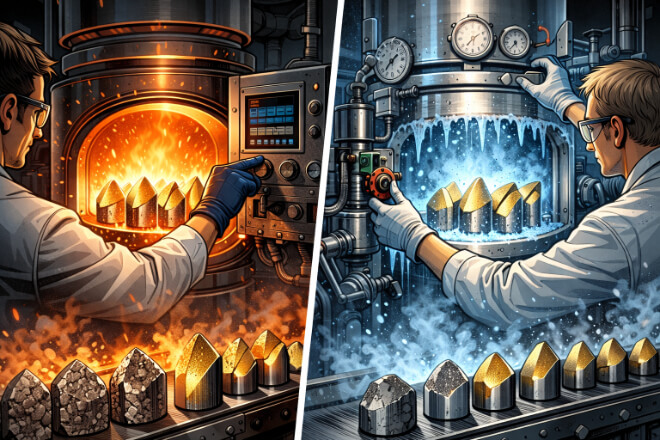

6. Grain Size Control in Tungsten Carbide Manufacturing

Manufacturers use several methods to control grain size in tungsten carbide tips.

By adjusting the sintering temperature, pressure, and binder material, they can create a material that meets specific performance requirements.

Key Factors in حجم الحبوب Control:

عملية التلبيد:

The temperature and pressure used during sintering (the process where tungsten carbide particles are fused together) have a significant effect on grain size.

Higher sintering temperatures typically result in larger grains, while lower temperatures produce smaller grains.

محتوى المجلد:

The type and amount of binder material used can also influence the grain size.

For example, cobalt is commonly used as a binder in tungsten carbide, and varying its proportion can impact the final grain structure.

Cooling Rate:

The cooling process after sintering also affects grain growth. Slower cooling rates can lead to larger grains, while rapid cooling typically results in smaller grains.

These factors must be carefully controlled to produce tungsten carbide tips that are tailored for specific cutting tasks.

7. Applications of Tungsten Carbide Tips with Controlled Grain Size

The ability to control grain size makes tungsten carbide tips versatile and suitable for a wide range of applications.

By adjusting حجم الحبوب, manufacturers can optimize carbide tips for different tasks, ensuring better performance and tool longevity.

Applications Include:

القطع الدقيق: Fine-grain tungsten carbide is ideal for high-precision applications like CNC machining, where wear resistance and sharpness are critical.

Heavy-Duty Cutting: Coarse-grain tungsten carbide is often used in التعدين, drilling, and construction tools where impact resistance is more important than wear resistance.

Milling and Drilling: Carbide tips with intermediate grain sizes offer a good balance for milling and drilling applications, where both wear resistance and toughness are required.

By selecting the appropriate grain size for a given application, industries can ensure optimal tool performance and durability.

8. Cost Benefits of Controlling Grain Size in Tungsten Carbide Tips

While controlling حجم الحبوب in tungsten carbide manufacturing can increase the complexity of production, it offers significant cost benefits over the long term by improving tool performance and lifespan.

Cost Benefits Include:

Fewer Tool Changes: Tools with optimal grain sizes last longer, reducing the need for frequent replacements.

تقليل وقت التوقف: Longer tool life means less downtime for maintenance and tool replacements, leading to increased productivity.

Improved Cutting Efficiency: Tools that maintain their sharpness longer lead to smoother, faster cutting operations, reducing labor costs and improving overall operational efficiency.

In the long run, controlling grain size offers significant cost savings for industries that rely on cutting tools for high-performance applications.

خاتمة

Grain size control is a critical factor in the design and performance of tungsten carbide tips.

By balancing hardness and toughness through careful grain size management, manufacturers can create tips that offer superior wear resistance and durability for a wide range of cutting applications.

Whether for high-precision machining or heavy-duty cutting jobs, tungsten carbide tips with optimized grain sizes provide excellent performance, increased tool life, and cost savings.

Understanding the role of grain size is essential for industries that depend on durable, high-performing cutting tools.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.