في قطاع التصنيع الحديث، يتزايد الطلب على إنتاج أسرع ودقة أعلى من أي وقت مضى. سواءً في صناعات السيارات، أو الفضاء، أو النفط والغاز، أو الطب، تعتمد المصانع على أدوات قطع عالية الجودة لتلبية متطلبات دقيقة ومواعيد نهائية صارمة. ومن أبرز الحلول أدوات قطع كربيد التنغستن. لقد غيّرت هذه الأدوات طريقة تشكيل المواد وقطعها وتشطيبها. ولكن لماذا هي بهذه الفعالية؟

تشرح هذه المقالة كيف تعمل أدوات القطع المصنوعة من كربيد التنغستن على تحسين كل من الكفاءة والدقة، ولماذا يختارها المصنعون في مختلف الصناعات بدلاً من الأدوات التقليدية.

ما هو كربيد التنغستن؟

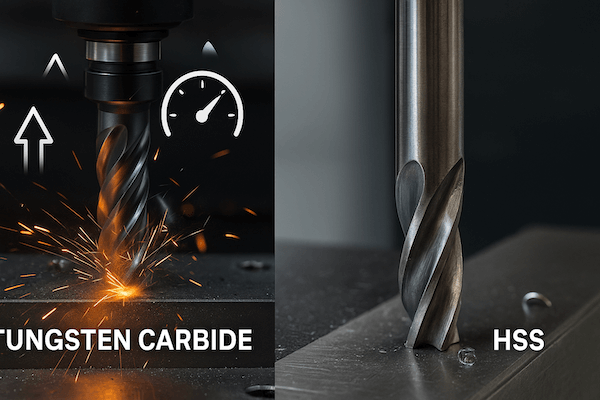

كربيد التنغستن مركبٌ يُصنع من مزيج التنغستن والكربون. وهو من أصلب المواد المستخدمة في أدوات القطع، بعد الماس مباشرةً. يمتاز هذا المركب بصلابةٍ ومتانةٍ ومقاومةٍ للحرارة.

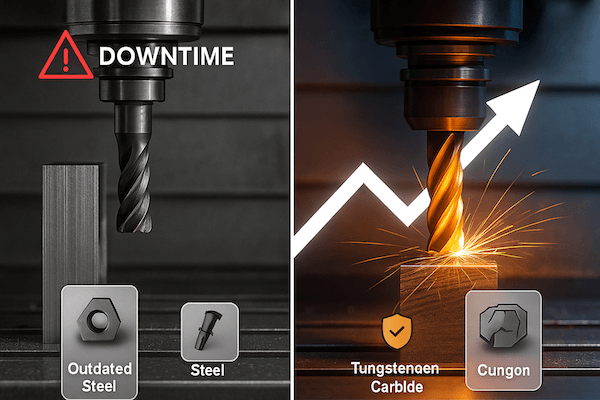

الأدوات المصنوعة من كربيد التنغستن أقوى بكثير وتدوم لفترة أطول من الأدوات المصنوعة من الفولاذ عالي السرعة (HSS). هذا يعني أنها تحافظ على شكلها وحدتها حتى في ظروف الضغط العالي ودرجات الحرارة العالية.

لماذا تعتبر كفاءة التصنيع مهمة

كفاءة التشغيل تعني إنتاجًا أسرع مع تغييرات أقل للأدوات، مما يؤدي إلى تقليل وقت التوقف عن العمل وخفض التكلفة.

تزيد أدوات كربيد التنغستن من الكفاءة من خلال:

الحفاظ على الحواف الحادة لفترات أطول.

تقليل تكرار تغيير الأداة بسبب عمرها الطويل.

تتمتع بسرعات قطع أعلى مقارنة بأدوات HSS.

تخفيض معدلات الخردة بفضل القطع النظيفة والمتسقة.

عندما تتحول المتاجر إلى أدوات الكربيد، فإنها غالبًا ما تشهد انخفاضًا في أوقات الدورة بما يصل إلى 50%.

لماذا الدقة مهمة في التصنيع

في صناعات مثل الطب والفضاء والإلكترونيات، تُعد الدقة أمرًا بالغ الأهمية. حتى الخطأ البسيط قد يؤدي إلى تلف الأجزاء أو مشاكل تتعلق بالسلامة.

تعمل أدوات القطع المصنوعة من كربيد التنغستن على تحسين الدقة من خلال:

الحفاظ على الاستقرار الأبعادي عند السرعات العالية.

توفير تشطيبات ناعمة ونظيفة.

تقليل الاهتزاز والانحراف أثناء التشغيل.

نظرًا لأنها تحافظ على شكلها لفترة أطول، فإن أدوات الكربيد تقلل من خطر عدم الدقة الناتج عن تآكل الأداة.

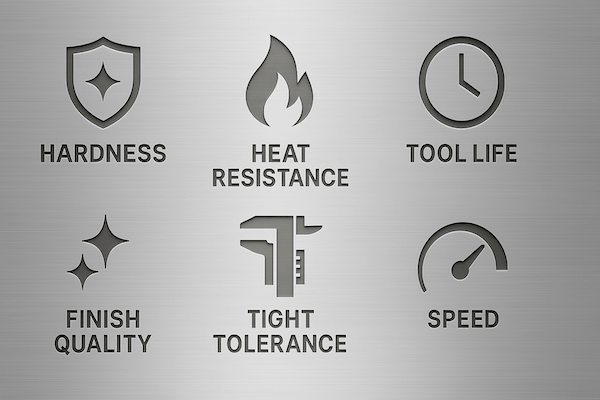

الفوائد الرئيسية لأدوات القطع المصنوعة من كربيد التنجستن

فيما يلي أهم مزايا استخدام كربيد التنغستن في تصنيع الآلات ذات التحكم الرقمي:

عالي صلابة - ممتاز لقطع المواد الصلبة مثل الفولاذ والحديد الزهر والمواد المركبة.

مقاومة للحرارة - مثالية للعمليات عالية السرعة دون فقدان الصلابة.

عمر أطول للأداة - يقلل من الاستبدال ووقت التوقف عن العمل.

تشطيب السطح الجودة - تنتج حواف ناعمة وخالية من النتوءات.

تحملات ضيقة - مثالية للمكونات عالية الدقة.

هل ترغب في استكشاف أنواع الأدوات؟ تفضل بزيارة كتالوج أدوات القطع لدينا لمزيد من المعلومات.

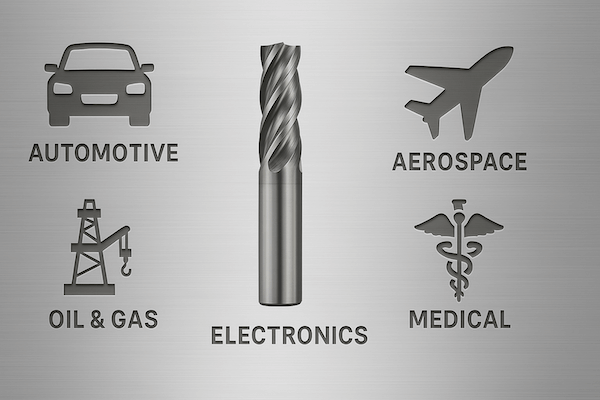

التطبيقات عبر الصناعات

تُستخدم أدوات القطع المصنوعة من كربيد التنغستن في العديد من الصناعات، بما في ذلك:

السيارات - لأجزاء المحرك والتروس والفرامل.

الفضاء الجوي - لشفرات التوربينات والأجزاء الهيكلية والمعادن خفيفة الوزن.

النفط والغاز - لمكونات الصمامات ومعدات الحفر والمضخات.

طبي - للأدوات الجراحية والغرسات.

الالكترونيات - للموصلات ولوحات الدوائر والطحن الدقيق.

تعرف على المزيد حول كل حالة استخدام في دليلنا: أفضل تطبيقات أدوات القطع المصنوعة من كربيد التنغستن عبر الصناعات.

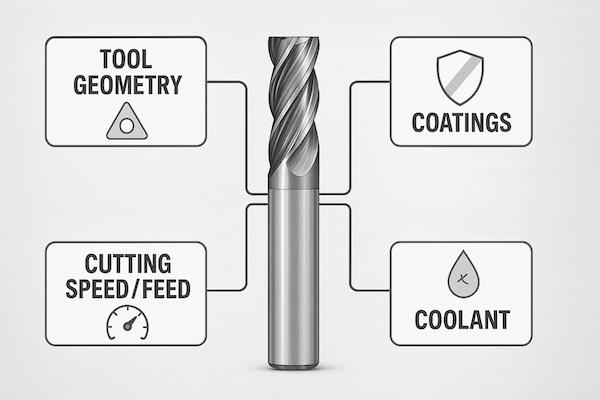

العوامل المؤثرة على أداء الأداة

للحصول على أقصى استفادة من أدوات كربيد التنغستن، من المهم مراعاة ما يلي:

هندسة الأدوات - الأشكال المختلفة تناسب مواد مختلفة.

الطلاءات - تعمل الطلاءات المصنوعة من TiN وTiAlN والماس على تعزيز المتانة.

ظروف القطع - استخدم التغذية والسرعات الصحيحة.

استخدام سائل التبريد – يساعد على إدارة الحرارة وإطالة عمر الأداة.

هل تحتاج إلى مساعدة في اختيار الدرجة المناسبة؟ اقرأ دليل اختيار درجة الكربيد.

لماذا تختار Retop كمورد لك؟

في ريتوب، نُنتج أدوات قطع عالية الأداء من كربيد التنغستن منذ أكثر من 14 عامًا. نخدم عملاء في أكثر من 50 دولة بـ:

تصميم الأدوات المخصصة والنماذج الأولية

إنتاج حاصل على شهادة ISO 9001

مرونة الحد الأدنى لكمية الطلب والتسليم السريع

دعم الخبراء من فريقنا الفني

اكتشف المزيد في www.retopz.com واكتشف كيف يمكن لأدواتنا أن تعزز قدراتك في التصنيع.

خاتمة

تُعد أدوات القطع المصنوعة من كربيد التنغستن خيارًا ذكيًا للشركات التي تسعى إلى تحسين كفاءة ودقة التشغيل. بفضل قدرتها على القطع بشكل أسرع، وعمرها الطويل، وتفاوتات تحملها، تُمثل هذه الأدوات ترقيةً جوهريةً مقارنةً بالأدوات التقليدية مثل الفولاذ عالي السرعة (HSS). سواءً كنت تعمل في مجال الطيران، أو السيارات، أو الطب، أو تشغيل المعادن، فإن التحول إلى أدوات الكربيد يُحسّن أرباحك بشكل كبير.

هل أنت مستعد لتحديث أدواتك؟ تفضل بزيارة موقعنا صفحة أدوات قطع كربيد التنغستن للحصول على التفاصيل أو لطلب عرض أسعار.