أدوات قطع كربيد التنغستن are known for being super tough and long-lasting. But like any tool, they eventually wear out.

Using a dull or damaged tool can ruin your part, slow down your machines, and even cause more serious problems.

If you’re managing a shop or responsible for keeping production smooth, knowing when to swap out a worn tool is a big deal.

This guide breaks down the clear signs that it’s time to retire a tungsten carbide cutting tool—and why changing it on time actually saves you money.

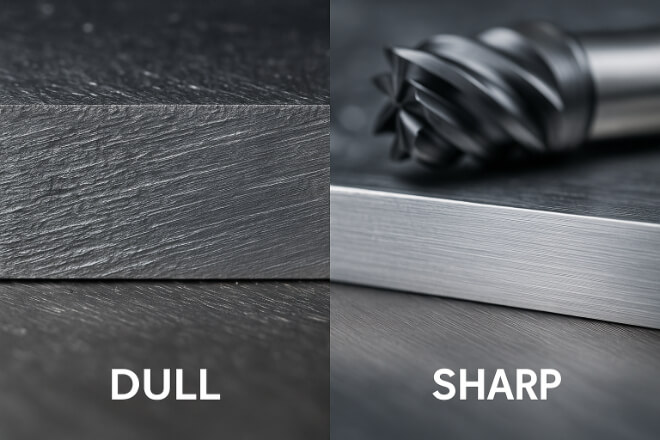

1. Surface Finish Looks Rough

If your parts start to look rough or uneven, it could be your cutting tool’s fault.

Dull tools can’t cut cleanly—they rub more than they slice, which leads to poor surface finishes.

When you see scratches, lines, or just a messy finish on your parts, it’s a sign your tool has lost its edge. That often means extra time fixing parts or tossing them in the scrap bin.

2. Your Machine Is Working Too Hard

If the machine starts making strange noises or seems like it’s working harder than usual, pay attention.

Worn tools make your machine work overtime, increasing spindle load and creating unnecessary stress.

Watch for rising power usage or spindle pressure. If those numbers climb while performance drops, it’s probably time for a tool change.

3. Tools Don’t Last As Long As They Used To

Tungsten carbide tools are meant to last. But if your tools are burning out faster than they used to, something’s off. Maybe the coating wore down or you’re pushing the tool past its limit.

Keep a log of how long each tool lasts. If the numbers drop without a clear reason, it’s a good sign the tool needs replacing.

4. Chips, Cracks, or Edge Damage

Even though carbide is super strong, it’s not unbreakable. Over time, the edges can chip or crack—especially if you’re cutting hard materials or using aggressive speeds.

Take a look at the tool edges. If you see small cracks, missing corners, or rough spots, don’t wait. A small chip can turn into a major failure quickly.

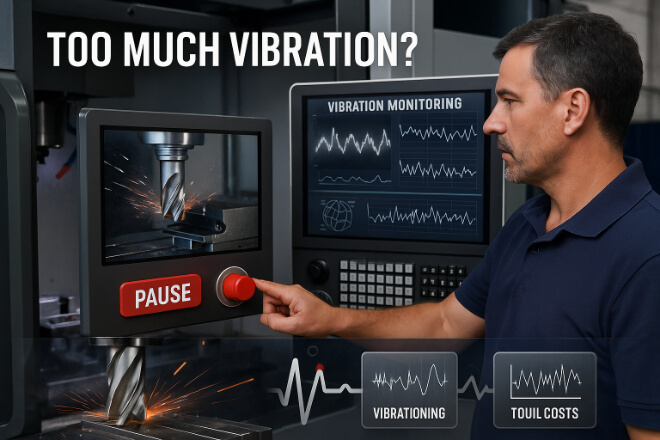

5. Vibration or Chatter Gets Worse

If your machine starts vibrating or making a chattering sound while cutting, that’s a problem. It usually means the tool is worn or out of balance.

This kind of vibration messes with part accuracy and can even damage your machine. If it wasn’t happening before, it might be time for a fresh tool.

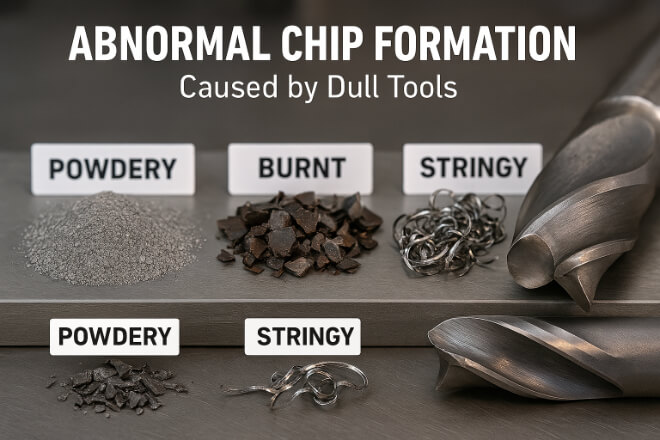

6. Weird-Looking Chips

Healthy tools make clean, predictable chips. But if you start seeing powdery chips, burnt edges, or long tangled ones, something’s wrong.

Chips say a lot about cutting conditions. When they change, your tool might be dull or coated in material buildup.

7. Heat and Burn Marks

If your parts or tools come out with blue, brown, or purple spots, that’s heat damage.

It means the tool is creating more friction than it should, probably because it’s not cutting well anymore.

Heat not only affects part quality, but it can also mess with the tool’s hardness and cause coatings to wear out faster.

8. Parts Are Out of Tolerance

Precision is the name of the game. If your parts aren’t staying within spec, check your tools. A dull edge or worn corner can throw off the dimensions.

If your first few parts are perfect, but the next batch starts drifting, that’s a strong clue the tool is the issue.

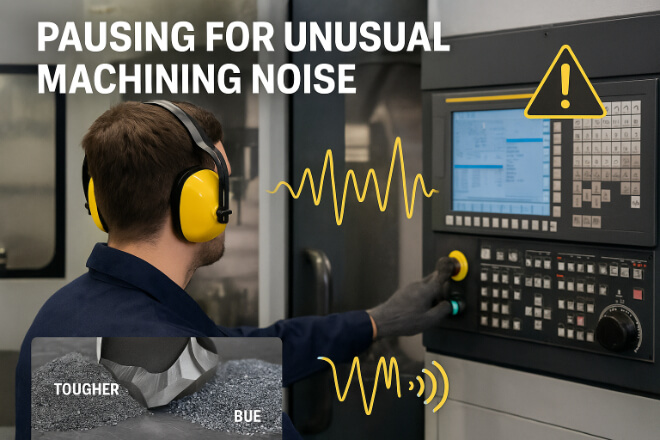

9. Cutting Sounds Change

Experienced operators often tell when a tool’s going bad just by listening. A sharp tool cuts clean and sounds smooth. A dull one might squeak, grind, or make popping noises.

If your ears tell you something’s off, it’s worth stopping to check.

10. Coating Is Wearing Off

Most carbide tools have coatings to help them last longer and handle heat better.

Over time, these coatings fade or wear down. When you notice the coating looks thin, patchy, or scratched, the tool might be nearing its end.

Without that protective layer, the tool takes more heat and wear directly—which shortens its life.

11. Reground Tool Still Performs Poorly

Regrinding can breathe new life into a carbide tool. But if you’ve reground it and it still doesn’t perform well—or it wears out again fast—it’s probably time for a full replacement.

Sometimes it’s just not worth regrinding a tool again. A fresh one could save time and cut better.

12. Quick Tips for Keeping Track of Tool Condition

To avoid nasty surprises or wasted parts, get into the habit of monitoring tools:

Track tool hours or part count

Check tools visually during setup and cleanup

Listen for strange sounds during cutting

Use machine data like spindle load or vibration levels

These small habits can go a long way in helping you catch issues before they cause bigger problems.

الأفكار النهائية

Tungsten carbide tools are tough—but they’re not forever. Replacing them at the right time saves your parts, your machines, and your budget.

Watch for signs like poor finishes, odd sounds, tool chips, and excess heat. The sooner you spot problems, the smoother your operation will run.

Ready for reliable replacements? Visit ريتوبز to find cutting tools that are built to perform.