Tungsten carbide cutters are some of the most reliable and high-performance tools used in today’s manufacturing and industrial sectors.

Known for their exceptional صلابة, durability, and resistance to wear, these tools are essential for precision cutting, shaping, and material removal across many industries.

In this article, we’ll explore how tungsten carbide cutters work, their key advantages, and where they’re most often used.

If you’re a decision-maker in machining, metalworking, or manufacturing, understanding the value of these tools can help improve your productivity, reduce waste, and boost performance.

What Are Tungsten Carbide Cutters?

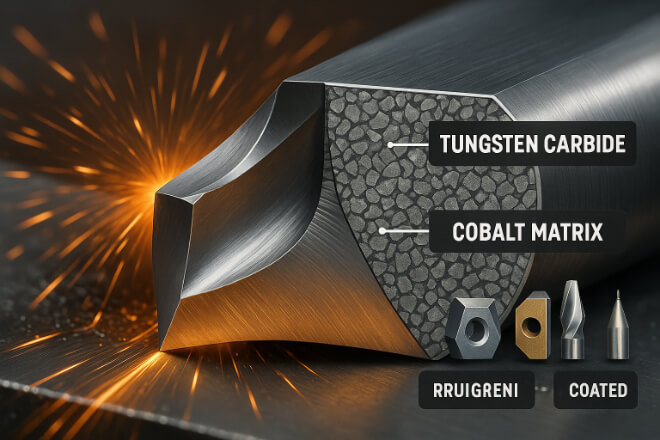

Tungsten carbide cutters are tools made from a composite material that combines tungsten and carbon atoms, forming one of the hardest materials available for industrial use.

These cutters are known for their strength, high heat resistance, and long tool life.

The material is much harder than steel and can maintain its cutting edge for a long time without getting dull. That’s why it’s widely used in CNC machining, milling, drilling, and grinding.

How Tungsten Carbide Cutters Are Made

The manufacturing process of tungsten carbide cutters involves several precise steps:

Powder Mixing: Tungsten carbide powder is mixed with a binding metal (usually cobalt).

Pressing: The mixture is pressed into shape.

Sintering: The formed shape is heated in a furnace to make the material dense and hard.

Finishing: The cutter is ground, coated, and sharpened to its final geometry.

This process ensures that each cutter is tough, durable, and ready for heavy-duty use.

Common Applications of Tungsten Carbide Cutters

Tungsten carbide cutters are used in many sectors where precision and strength are required. Below are some of the most common applications:

1). السيارات صناعة

Used for machining engine blocks, gear components, and brake rotors. Carbide tools are critical for precision and durability.

2). الفضاء الجوي صناعة

Tungsten carbide cutters help machine high-strength alloys like titanium and Inconel used in jet engines and structural parts.

3). Metalworking & Fabrication

Ideal for cutting, drilling, and shaping metals such as steel, aluminum, and cast iron.

4). نجارة

Even though metals are the focus, tungsten carbide is also used in woodworking blades for extended life and better cutting precision.

Used in the production of surgical instruments and implants due to the need for fine tolerances and clean finishes.

Carbide cutters are used in drilling tools and wear-resistant parts that operate in high-pressure, abrasive conditions.

Key Advantages of Tungsten Carbide Cutters

There are many reasons why tungsten carbide tools are preferred in industrial settings. Let’s break down the biggest advantages:

1) متطرف صلابة and Durability

Tungsten carbide ranks around 9 on the Mohs hardness scale. It stays sharp much longer than high-speed steel or ceramic tools.

2). Heat Resistance

These cutters can withstand very high cutting temperatures without losing hardness, allowing faster machining speeds.

3). Precision and Accuracy

With a sharper edge and stable geometry, tungsten carbide cutters produce clean, precise cuts, reducing the need for rework.

4). Longer Tool Life

Carbide tools last much longer than traditional tools, which reduces the cost and time involved in frequent tool changes.

5). Versatility

They can be used on hard materials like hardened steel, stainless steel, and composites, making them suitable for a wide range of applications.

6). Improved Surface Finish

Thanks to their sharp edges and solid structure, carbide tools produce smoother finishes that need less polishing.

Comparing Tungsten Carbide with Other Cutting Tool Materials

Here’s a quick comparison table:

| Tool Material | صلابة | مقاومة الحرارة | أداة الحياة | التطبيقات |

|---|---|---|---|---|

| الفولاذ عالي السرعة (HSS) | واسطة | منخفض إلى متوسط | قصير | التشغيل الآلي للأغراض العامة |

| سيراميك | عالي | عالي | معتدل | Finishing hard materials |

| كربيد التنغستن | عالية جدًا | عالية جدًا | طويل | High-speed, high-precision applications |

Factors to Consider When Choosing Tungsten Carbide Cutters

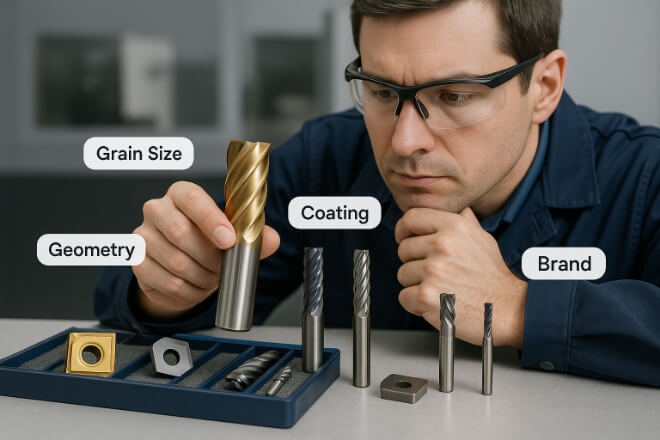

Not all carbide tools are the same. Before buying, decision-makers should evaluate:

Grain size: Finer grains often mean tougher tools for delicate cuts.

Coatings: TiAlN, TiCN, and DLC coatings can improve tool performance and life.

Geometry: Choose cutters with the right flute design, helix angle, and edge prep for your application.

Brand reputation: Always select reliable suppliers with consistent product quality.

Maintenance Tips to Extend Tool Life

To get the best return on your investment, proper maintenance is key:

Clean tools after use to remove built-up material

Store them in dry, padded holders to avoid chips

Monitor for signs of wear or micro-cracks

Regrind tools when necessary

Don’t push the tools beyond recommended feeds and speeds

الأفكار النهائية

Tungsten carbide cutters offer superior performance, especially in demanding cutting tasks.

Their ability to stay sharp, resist heat, and handle tough materials makes them an ideal choice for decision-makers in manufacturing.

By selecting high-quality tools, understanding their applications, and maintaining them well, your operations can save time, improve results, and reduce tooling costs.

If you’re ready to upgrade your cutting performance, visit ريتوبز for reliable carbide solutions.