في الصناعات مثل التعدين, النفط والغاز, تشكيل المعادن, النجارة، وفي التصنيع، تعتبر المواد المقاومة للتآكل أمرًا بالغ الأهمية.

عند تشغيل المعدات في بيئات قاسية، يجب أن تتحمل أجزاؤها الاحتكاك والضغط والحرارة والتآكل. اثنتان من أكثر المواد شيوعًا لـ أجزاء التآكل هي عبارة عن كربيد التنغستن والفولاذ.

يؤثر اختيار المادة المناسبة على الإنتاجية والتكاليف ووقت التوقف. تُقارن هذه المقالة بين كربيد التنغستن والصلب من حيث الأداء والتكلفة والمتانة وأفضل التطبيقات، مما يُساعد صانعي القرار على اختيار المادة المناسبة لعملياتهم.

ما هو كربيد التنغستن؟

كربيد التنغستن مركبٌ مصنوعٌ من ذرات التنغستن والكربون. يتميز بصلابةٍ فائقة، تكاد تضاهي صلابة الماس، مع متانةٍ جيدة.

وهذا يجعلها خيارًا مثاليًا لأجزاء التآكل التي تواجه التآكل المستمر أو الظروف القاسية.

الخصائص الرئيسية لكربيد التنغستن:

عالية جدًا صلابة (8.5–9 على مقياس موس)

ممتاز مقاومة التآكل

مقاومة عالية للحرارة

مقاومة جيدة للتآكل

عمر خدمة طويل

تشمل الاستخدامات الشائعة أدوات القطع، ورؤوس الحفر في التعدين، وأختام المضخات، وبطانات التآكل، والقوالب الدقيقة.

ما هو الفولاذ؟

الفولاذ عبارة عن سبيكة مصنوعة بشكل أساسي من الحديد والكربون، وغالبًا مع عناصر أخرى مثل الكروم أو النيكل أو المنغنيز لتحسين الأداء.

يُعد الفولاذ شائعًا لقوته وصلابته وتعدد استخداماته. كما أنه أسهل وأقل تكلفة في التصنيع واللحام مقارنةً بكربيد التنغستن.

الخصائص الرئيسية للصلب:

عالي صلابة والقوة

أسهل في التصنيع والتشكيل

فعالة من حيث التكلفة للأجزاء الكبيرة

درجات مختلفة لاستخدامات مختلفة (على سبيل المثال، فولاذ الأدوات، والفولاذ المقاوم للصدأ، والفولاذ عالي الكربون)

يتم استخدام الفولاذ على نطاق واسع في التروس، والأعمدة، والأجزاء الهيكلية، والمكونات الهندسية العامة.

كربيد التنغستن مقابل الفولاذ: مقارنة الخصائص

| ملكية | كربيد التنغستن | فُولاَذ |

|---|---|---|

| صلابة | عالية للغاية (8.5–9 موس) | أقل (4-8 موس، حسب الدرجة) |

| مقاومة التآكل | ممتاز، مثالي للظروف الكاشطة | جيد، لكنه يتآكل بشكل أسرع عند التآكل |

| مقاومة الحرارة | عالية جدًا، تحتفظ بالصلابة في درجات الحرارة العالية | معتدل، قد يفقد صلابته عند درجات الحرارة العالية |

| مقاومة التآكل | عالية، وخاصة مع الطلاءات | يختلف - الفولاذ المقاوم للصدأ يقاوم التآكل بشكل جيد |

| صلابة | متوسط (يمكن أن يتشقق تحت تأثير صدمة شديدة) | عالية، أفضل للأحمال المؤثرة |

| قابلية التصنيع | صعب، ويتطلب أدوات من الماس أو الكربيد | سهلة التشغيل باستخدام الأدوات القياسية |

| يكلف | أعلى | أدنى |

المتانة في الظروف القاسية

يتميز كربيد التنغستن بمقاومته للتآكل والتآكل.

في التعدين أو تشكيل المعادن، غالبًا ما تدوم الأدوات والمكونات المصنوعة من كربيد التنغستن لفترة أطول من نظيراتها من الفولاذ بما يتراوح بين 3 و10 أضعاف. وهذا يقلل من وقت التوقف عن العمل وتكاليف الاستبدال.

ومع ذلك، يمكن للصلب أن يتفوق على كربيد التنغستن عندما تتعرض أجزاؤه لتأثيرات ثقيلة أو قوى انحناء.

الفولاذ أعلى صلابة وهذا يعني أنه قادر على امتصاص الصدمات دون أن يتشقق، مما يجعله أفضل لبعض التطبيقات الهيكلية.

اعتبارات التكلفة

للوهلة الأولى، تبدو قطع كربيد التنغستن أغلى من الفولاذ. ومع ذلك، عند احتساب تكلفة دورة الحياة الإجمالية - بما في ذلك الاستبدالات ووقت التوقف عن العمل والصيانة - غالبًا ما يكون كربيد التنغستن أكثر توفيرًا.

على سبيل المثال، قد تكلف قوالب القطع المصنوعة من كربيد التنغستن 2-3 مرات أكثر من قوالب الفولاذ ولكنها تدوم 5-10 مرات أطول، مما يجعلها الاستثمار الأفضل في كثير من الحالات.

ملاءمة التطبيق

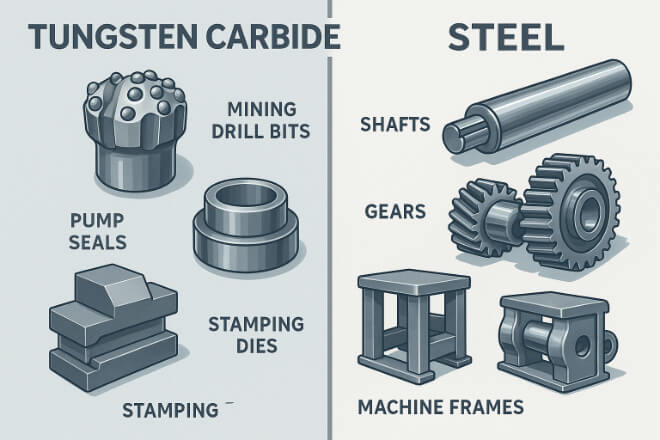

١) متى يُستخدم كربيد التنغستن:

التآكل والتلف الشديد

درجات حرارة عالية

التفاوتات الدقيقة

التشغيل المستمر مع الحد الأدنى من وقت التوقف المسموح به

1.1). أمثلة:

رؤوس حفر التعدين

أختام المضخة في النفط والغاز

قوالب ختم المعادن

شفرات النجارة

2) متى نستخدم الفولاذ:

أحمال الصدمات الثقيلة والانحناء

بيئات ذات درجات حرارة منخفضة

التطبيقات حيث التكلفة هي العامل الرئيسي

أجزاء كبيرة قد تكون باهظة الثمن في الكربيد

2.1). أمثلة:

إطارات الآلات

الأعمدة والتروس

المكونات الهيكلية العامة

ملخص الإيجابيات والسلبيات

| مادة | الايجابيات | سلبيات |

|---|---|---|

| كربيد التنغستن | مقاومة ممتازة للتآكل، صلابة عالية، مقاومة جيدة للحرارة والتآكل، عمر طويل | غالي الثمن، هش تحت الصدمات الثقيلة، يصعب تصنيعه |

| فُولاَذ | صلابة عالية، تكلفة أقل، سهولة التصنيع، متعددة الاستخدامات | مقاومة أقل للتآكل، قد تفقد صلابتها في درجات الحرارة العالية، وتحتاج إلى مزيد من الصيانة |

الاختيار بين كربيد التنغستن والفولاذ

يعتمد اختيار المادة المناسبة على:

نوع التآكل - كاشط، لاصق، صدمي، أو تآكلي

درجة حرارة التشغيل - قد تتطلب العمليات ذات الحرارة العالية استخدام الكربيد

حجم القطعة – الفولاذ أكثر اقتصادا للأجزاء الكبيرة

متطلبات عمر الخدمة - غالبًا ما يعني الكربيد عددًا أقل من عمليات الاستبدال

الميزانية - التخطيط للتكاليف على المدى القصير مقابل المدى الطويل

بالنسبة للعديد من الصناعات، فإن النهج الأفضل هو الجمع بين استخدام الفولاذ للدعم الهيكلي وكربيد التنغستن لأسطح التآكل.

نصائح الصيانة لتحقيق أقصى قدر من الأداء

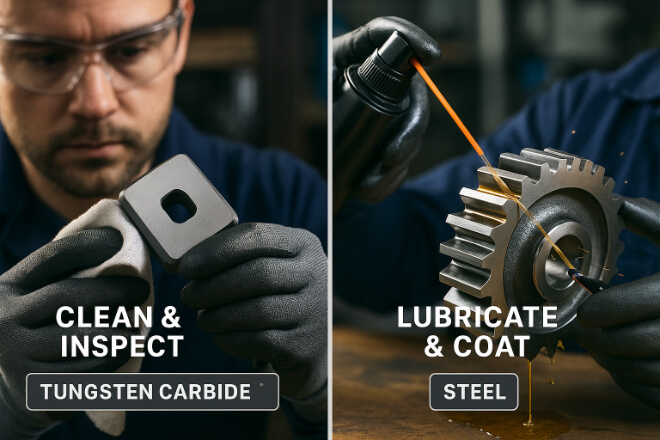

1) بالنسبة لكربيد التنغستن:

تجنب الصدمات المفاجئة

استخدم التركيب المناسب لمنع تشققات الإجهاد

التنظيف بانتظام لتجنب التآكل الناتج عن المواد الكيميائية

2) بالنسبة للصلب:

تطبيق الطلاءات الواقية لمقاومة التآكل

الحفاظ على التزييت لتقليل التآكل

التحقق من وجود الشقوق أو التشوهات بشكل منتظم

خاتمة

في جدل كربيد التنغستن مقابل الفولاذ، لا يوجد فائز واحد. يهيمن كربيد التنغستن على تطبيقات مقاومة التآكل ودرجات الحرارة العالية، بينما يوفر الفولاذ متانة ومزايا اقتصادية للاستخدامات الهيكلية والشديدة التحمل.

ينبغي على صانعي القرار مراعاة التكلفة الإجمالية للملكية، واحتياجات الأداء، وظروف التشغيل. في كثير من الحالات، يُوفر الجمع بين المادتين في نظام واحد أفضل ما فيهما: المتانة والصلابة.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.