حلقات ختم الكربيد are critical components in pumps, compressors, and الصمامات for industries such as النفط والغاز, chemical processing, power generation, and marine systems.

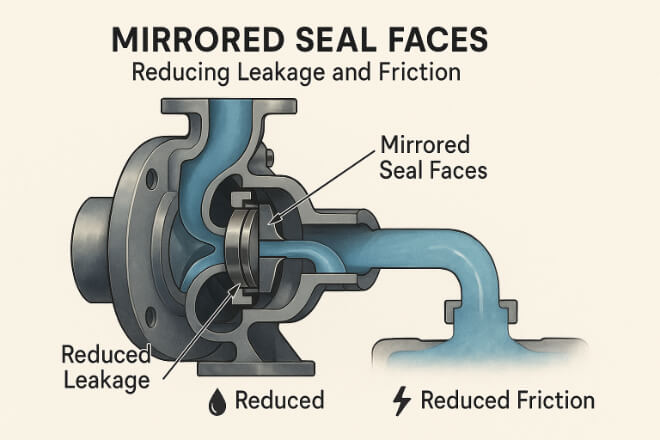

Achieving a mirror-level finish on these rings ensures leakage control, low friction, and long equipment life.

However, achieving a perfect mirror finish is not easy. It requires strict process windows, precise lapping and polishing techniques, and an understanding of common pitfalls that can compromise quality.

This guide provides decision-makers with practical insights into achieving high-quality finishes on carbide seal rings.

Why Mirror-Level Finishes Matter

Reduced friction: Smooth faces minimize energy loss.

Better sealing performance: Eliminates micro-leakage paths.

مقاومة التآكل: Stable surfaces extend component life.

Reliability in critical systems: Prevents unexpected seal failures.

Understanding Process Windows

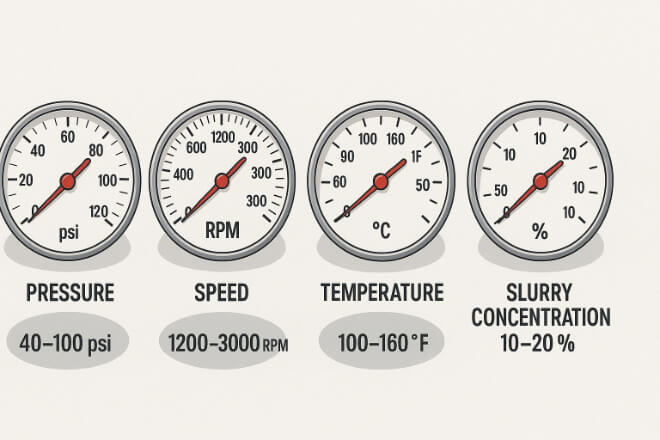

A process window defines the operating conditions—such as pressure, slurry type, speed, and temperature—that yield consistent results.

Staying within these windows ensures repeatability and avoids surface defects.

Key Process Window Parameters

1). Pressure:

Too high → Risk of surface distortion or micro-cracks.

Too low → Insufficient material removal, leading to poor finish.

2). Speed:

Optimal speed prevents heat buildup while ensuring efficient polishing.

3). Abrasive Type and Concentration:

Use diamond slurry with a consistent concentration for carbide.

4). Temperature Control:

Excess heat can warp or stress the carbide face, reducing flatness.

Lapping Techniques for Mirror Finishes

Lapping is the first step toward achieving flat, smooth surfaces.

Best Practices for Lapping

Select the right plate material: Cast iron or composite plates are ideal for carbide.

Use conditioning rings: Maintain plate flatness and distribute pressure evenly.

Check flatness frequently: Use optical flats and monochromatic light.

Alternate directions: Rotate parts periodically to avoid localized wear.

Polishing Techniques for Mirror Finishes

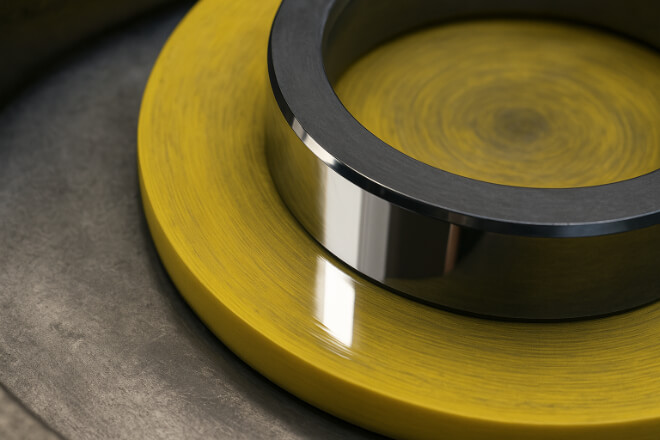

Polishing refines the surface after lapping to achieve the mirror-level finish.

Best Practices for Polishing

Use fine diamond paste or slurry: Grit size ≤1 μm for ultra-smooth results.

Control pressure and heat: Apply light pressure to avoid thermal damage.

Use clean pads and slurries: Contaminated abrasives can cause scratches.

Verify surface roughness (Ra): Target Ra ≤0.1 μm for mirror finishes.

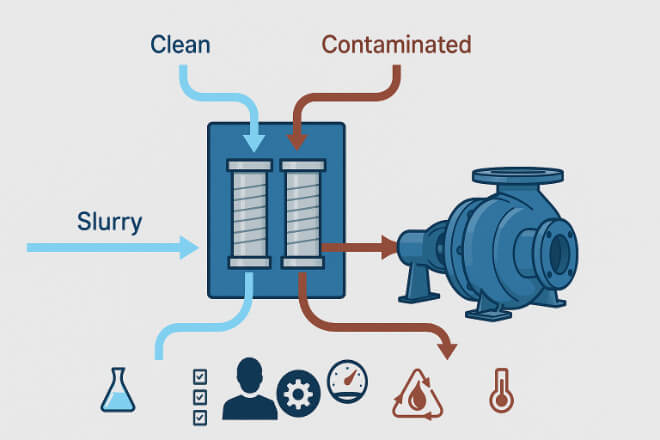

Slurry Management and Cleanliness

Proper slurry management is critical for consistent finishes.

Tips

Filter slurry regularly: Remove debris and worn abrasives.

Maintain proper concentration: Too much can scratch, too little reduces efficiency.

Keep the environment clean: Dust or particles can ruin polished surfaces.

Common Pitfalls and How to Avoid Them

| Pitfall | Cause | حل |

|---|---|---|

| Surface scratches | Contaminated slurry or pads | Use clean abrasives and pads |

| Warping or distortion | Excessive pressure or heat | Control temperature and pressure carefully |

| Inconsistent flatness | Uneven pressure or worn plates | Check plate condition and use conditioning rings |

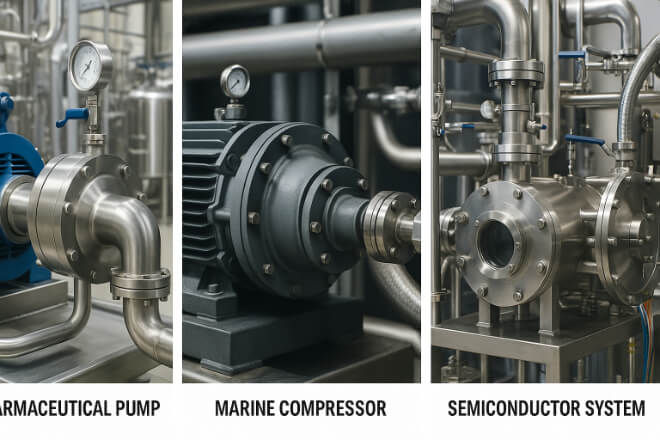

Industry Applications for Mirror-Level Finishes

Pharmaceutical equipment: Prevents contamination and ensures easy cleaning.

Semiconductor systems: Reduces particle generation and leakage.

Marine and oil & gas pumps: Improves lubrication and sealing under extreme conditions.

Power generation compressors: Extends life and improves energy efficiency.

نصائح الصيانة للأداء على المدى الطويل

Inspect seal faces regularly for scratches or wear.

Store carbide rings in clean, dry environments.

Re-polish slightly worn faces instead of replacing them completely.

Partner with suppliers who can provide precise Ra and flatness data.

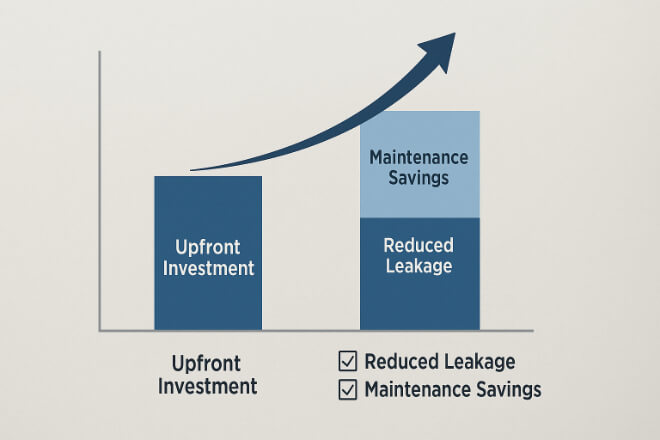

اعتبارات التكلفة والعائد على الاستثمار

Upfront cost: High-quality lapping and polishing equipment may cost more initially.

Savings: Mirror finishes reduce leakage and maintenance, saving on downtime.

ROI: Better sealing and lower energy usage offset the higher initial investment.

خاتمة

Achieving mirror-level finishes on carbide seal rings requires staying within process windows and avoiding common pitfalls.

By following best practices for lapping, polishing, slurry management, and maintenance, decision-makers can ensure reliable seals, lower costs, and improved equipment performance.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.