Additive manufacturing (AM), also known as 3D printing, is transforming the way industries produce parts, including tungsten carbide bushings.

As the demand for more complex and customized components increases, AM is emerging as a valuable solution for creating tungsten carbide bushing preforms.

These preforms serve as the foundation for the final bushing, offering improved design flexibility, reduced material waste, and enhanced performance.

In this blog, we’ll explore the latest trends in additive manufacturing for tungsten carbide bushing preforms and how these innovations are benefiting industries that rely on high-performance components.

What is Additive Manufacturing for Tungsten Carbide Bushing Preforms?

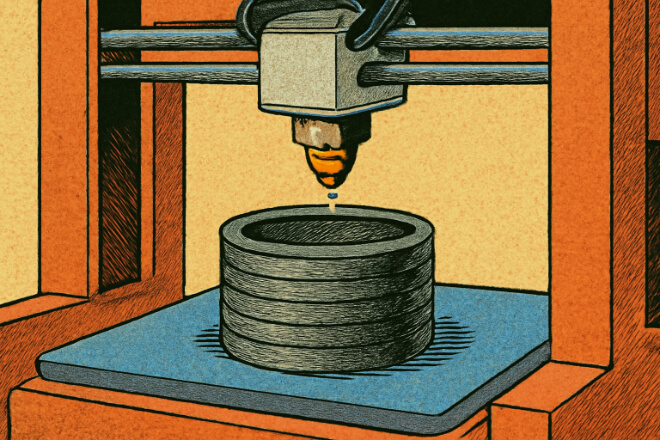

Additive manufacturing involves creating parts layer by layer from a digital model.

In the case of tungsten carbide bushing preforms, AM allows manufacturers to build complex shapes and geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Advantages of AM for Tungsten Carbide Preforms

Complex Designs: AM allows for the creation of intricate shapes that optimize the performance of the bushing.

Customization: Tailoring preforms for specific applications becomes easier, allowing for precise adjustments in material properties and dimensions.

Reduced Waste: Unlike traditional subtractive manufacturing methods, AM only uses the material needed, reducing waste and making the process more efficient.

Key Additive Manufacturing Techniques for Tungsten Carbide Preforms

Several additive manufacturing techniques are currently being used to produce tungsten carbide bushing preforms. Each method has its advantages, depending on the application and desired material properties.

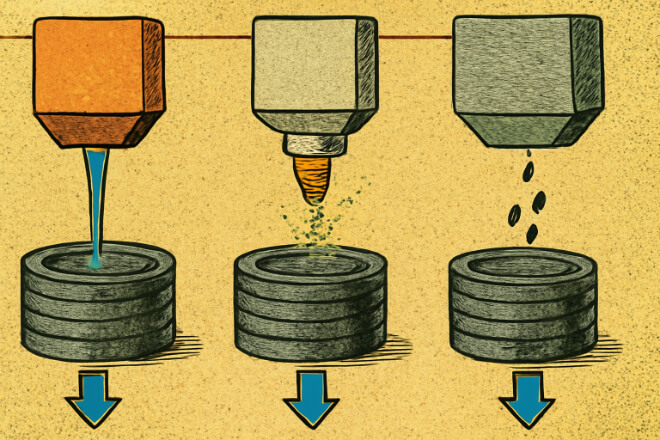

1). Selective Laser Sintering (SLS)

SLS uses a laser to sinter powdered tungsten carbide into the desired shape.

This process is ideal for creating highly detailed and dense preforms, which are then subjected to additional sintering to achieve the final hardness and toughness required for the bushing.

2. Direct Energy Deposition (DED)

DED is a technique where a focused energy source, such as a laser or electron beam, is used to melt the مسحوق كربيد التنغستن, allowing for the precise deposition of material in layers.

DED is particularly useful for creating complex geometries and repairs on existing components.

3. Binder Jetting

In binder jetting, a binder material is used to bond tungsten carbide powder, creating a preform that can then undergo sintering to achieve full density.

This method offers fast production times and cost-effective solutions, especially for large-scale production.

Trends in Additive Manufacturing for Tungsten Carbide Bushing Preforms

As additive manufacturing continues to evolve, several trends are shaping the production of tungsten carbide bushing preforms.

1). Integration of Advanced Materials

Advances in material science are enabling the use of high-performance tungsten carbide powders with customized binder materials.

These innovations allow for bushings with better مقاومة التآكل, enhanced صلابة, and improved مقاومة التآكل, even in the most demanding environments.

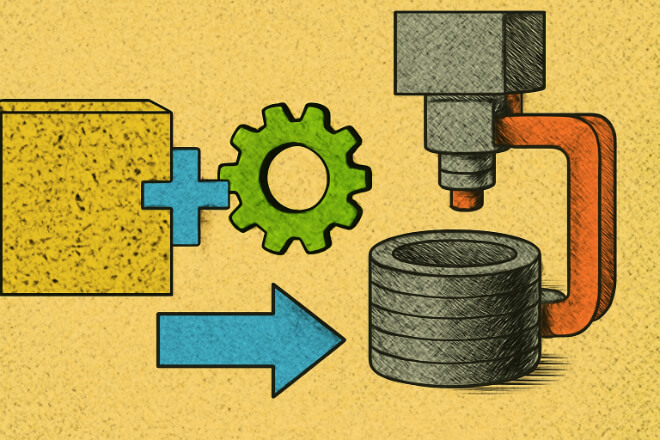

2). Hybrid Manufacturing Approaches

Hybrid manufacturing combines traditional and additive manufacturing techniques to create preforms with optimized material properties.

For example, a preform might be partially produced using AM techniques, then finished using traditional methods such as machining or grinding. This approach enables faster production while maintaining high-quality standards.

3). Speed and Efficiency Improvements

As AM technologies improve, the speed and efficiency of producing tungsten carbide preforms are increasing.

Faster processing times reduce lead times and make it possible to produce high-quality bushings in smaller quantities without sacrificing performance or cost.

4). Customization for Specific Applications

Additive manufacturing allows manufacturers to tailor tungsten carbide bushing preforms to the specific requirements of each application.

Whether it’s for high-pressure pumps, cryogenic environments, or abrasive slurry systems, AM enables the creation of bushings optimized for the unique challenges of each use case.

Benefits of Additive Manufacturing for Tungsten Carbide Bushing Preforms

Integrating additive manufacturing into the production of tungsten carbide bushing preforms offers several key benefits:

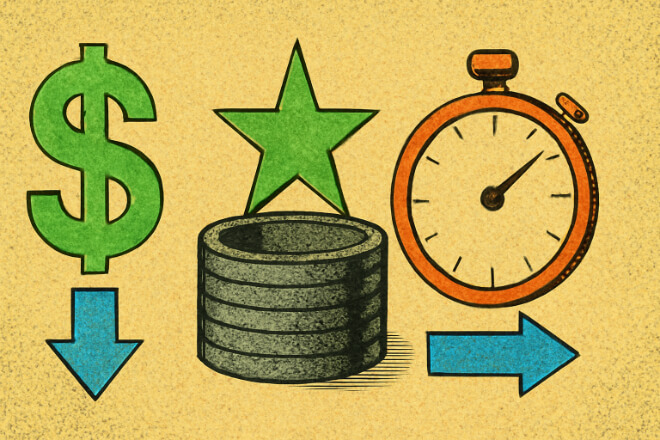

1). Cost Efficiency

AM reduces material waste and minimizes the need for complex tooling, leading to more cost-effective production.

Additionally, AM allows for on-demand production, reducing inventory costs and enabling faster time to market.

2). Improved Performance

With AM, manufacturers can design bushing preforms with complex internal features or cooling channels that enhance the overall performance and lifespan of the tungsten carbide bushings.

This results in better مقاومة التآكل and lower maintenance costs.

3). Shorter Lead Times

AM enables the rapid production of tungsten carbide bushing preforms with reduced lead times compared to traditional methods.

This is especially beneficial for industries that require custom or low-volume production.

Challenges and Limitations of Additive Manufacturing for Tungsten Carbide Preforms

Despite its advantages, additive manufacturing for tungsten carbide bushing preforms still faces some challenges:

1). Material Limitations

The range of available tungsten carbide powders for AM is still limited compared to traditional manufacturing methods. This can restrict the material properties and performance of the final product.

2). Post-Processing Requirements

Tungsten carbide preforms produced via AM typically require additional sintering, heat treatment, and finishing processes to achieve the desired hardness and toughness. This can add to the overall production time and cost.

3). Equipment Costs

While AM offers significant benefits in terms of customization and flexibility, the initial investment in AM equipment can be high.

Companies must carefully consider whether the long-term benefits justify the upfront cost.

خاتمة

Additive manufacturing is revolutionizing the production of tungsten carbide bushing preforms, offering greater customization, reduced material waste, and improved performance.

By leveraging advanced AM techniques, industries can create bushing preforms that are optimized for specific applications, whether for pumps, turbines, or compressors.

While challenges like material limitations and post-processing requirements remain, the benefits of AM make it a valuable tool for companies looking to enhance the performance and efficiency of their tungsten carbide bushings.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.