Tungsten carbide tips are widely used in a variety of industries due to their صلابة, مقاومة التآكل، والمتانة.

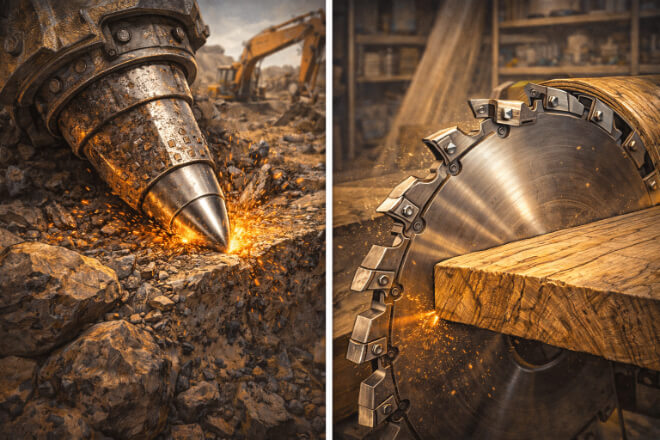

These tips are typically attached to the body of the cutting tool using one of two primary methods: brazing or mechanical clamping.

Each method has its advantages and applications, depending on factors like performance needs, cost considerations, and the type of work being done.

In this blog, we will compare brazing and mechanical clamping as attachment methods for tungsten carbide tips, helping you understand the benefits and challenges of each.

1. What Is Brazing?

Brazing is a process where a filler metal is used to bond the tungsten carbide tip to a tool body.

The process involves heating the metal to a temperature above 450°C (840°F), which allows the filler metal to flow into the joint between the carbide tip and the tool.

Once cooled, the filler metal solidifies, forming a strong bond.

Benefits of Brazing for Tungsten Carbide Tips:

Strong Bonding: Brazing provides a strong and durable bond, ensuring that the tungsten carbide tip remains securely attached to the tool during use.

مقاومة الحرارة: The brazed joint is heat-resistant, making it suitable for high-temperature applications where heat can degrade other attachment methods.

Smooth Surface Finish: Brazing produces a smooth, uniform surface, reducing the risk of tool wear and improving cutting performance.

Brazing is commonly used for high-precision tools where a strong bond is needed, and it is especially effective for larger tips that need to withstand high forces and wear.

2. What Is Mechanical Clamping?

Mechanical clamping involves physically securing the tungsten carbide tip to the tool body using a clamp or fastening device.

Unlike brazing, this method does not require heat, and the attachment is achieved through mechanical force. Clamps or screws are used to hold the carbide tip in place.

Benefits of Mechanical Clamping:

Easier to Replace: Mechanical clamping makes it easier to replace carbide tips, as the attachment does not rely on heat or permanent bonding. This can be advantageous for applications that require frequent tool changes.

Lower Initial Costs: Compared to brazing, mechanical clamping is often less expensive as it doesn’t require the use of filler metals or specialized heating equipment.

No Heat Exposure: Because there is no heat involved, the risk of damaging the tungsten carbide tip during the attachment process is eliminated.

Mechanical clamping is typically used in situations where the carbide tips may need to be replaced or adjusted frequently, or when a less expensive method is needed.

3. Comparing Brazing and Mechanical Clamping: Pros and Cons

Both brazing and mechanical clamping offer unique advantages, but they also come with their own set of challenges.

Understanding the pros and cons of each method can help you make an informed decision when selecting the attachment method for tungsten carbide tips.

1). Brazing: Pros and Cons

1.1). Pros:

Provides a very strong and permanent bond.

Ideal for high-temperature applications.

Can be used for complex or high-precision tools.

1.2). Cons:

More expensive than mechanical clamping due to the cost of filler materials and heating equipment.

Permanent bond, making tip replacement more difficult.

Requires precise control of heating temperatures to avoid damaging the carbide tip.

2). Mechanical Clamping: Pros and Cons

2.1). Pros:

Easier and faster to replace carbide tips.

Lower cost compared to brazing.

No heat exposure, which avoids potential damage to carbide tips.

2.2). Cons:

The bond may not be as strong as brazed joints, leading to potential tip loosening under extreme conditions.

Mechanical clamping may not be suitable for high-temperature or high-stress applications.

May require regular maintenance to ensure clamps are secure.

Both methods have their ideal use cases depending on the specific needs of the tool and the application.

4. Choosing the Right Attachment Method for Your Tool or Machine

The choice between brazing and mechanical clamping depends on several factors, such as the type of work being done, the required durability, and the need for tool replacement.

Here are some key considerations for selecting the right attachment method:

Factors to Consider:

Tool Use: For heavy-duty applications requiring high strength and مقاومة التآكل, brazing is often the preferred method. For lighter-duty applications or those requiring frequent tool changes, mechanical clamping may be more suitable.

Performance Requirements: If the tool needs to withstand high temperatures or heavy impact, brazing’s strength and heat resistance make it the better option.

Cost Constraints: Brazing is more expensive than mechanical clamping, so if cost is a primary concern and the tool doesn’t face extreme conditions, mechanical clamping might be more appropriate.

Ease of Replacement: If tool tips need to be replaced regularly or quickly, mechanical clamping offers the advantage of ease and speed in replacement.

By evaluating these factors, you can determine the most suitable attachment method based on the specific requirements of your tool and application.

5. Applications of Brazing vs Mechanical Clamping

Both brazing and mechanical clamping are used in various industries, and the choice of method largely depends on the application.

Here are some examples of where each attachment method is commonly used:

1). Applications for Brazing:

Precision Cutting Tools: Brazing is commonly used in tools where high precision and strength are required, such as saw blades, drills, and milling cutters.

High-Temperature Environments: For tools used in environments with high heat, such as those in the الفضاء الجوي و السيارات industries, brazing provides the necessary heat resistance.

Heavy-Duty Applications: Tools like التعدين drills and heavy construction machinery benefit from brazed tungsten carbide tips due to their ability to handle wear and stress.

2). Applications for Mechanical Clamping:

Machinery with Replaceable Tips: Tools that require frequent tip changes, such as some types of grinders or shredders, benefit from mechanical clamping.

Lower-Cost Tools: In situations where cost is a significant factor, and high heat or impact resistance is not a primary concern, mechanical clamping is used for attaching carbide tips.

Light- to Medium-Duty Cutting: For tools used in lighter cutting tasks, such as woodworking or plastic cutting, mechanical clamping provides an efficient and cost-effective attachment solution.

Both methods are valuable in different scenarios, and the best choice depends on the application and tool performance requirements.

6. Cost Considerations: Brazing vs Mechanical Clamping

Cost is often a deciding factor when selecting an attachment method for carbide tips.

Although brazing provides a stronger and more permanent bond, it comes with higher initial costs. Mechanical clamping, on the other hand, is generally more affordable.

Cost Breakdown:

Brazing: Typically involves the cost of filler metals, heating equipment, and skilled labor, making it more expensive.

Mechanical Clamping: Involves the cost of clamps, screws, or fastening mechanisms, which are generally lower in price compared to brazing.

Despite the higher initial cost of brazing, its longevity and strength may offer better value in the long run for tools that require durability and performance in high-impact or high-temperature environments.

خاتمة

The choice between brazing and mechanical clamping for attaching tungsten carbide tips depends on factors such as the type of tool, its intended use, cost constraints, and maintenance requirements.

Brazing offers superior strength, heat resistance, and longevity, making it ideal for heavy-duty and high-precision applications.

Mechanical clamping, while more cost-effective and easier to maintain, is better suited for tools that require frequent tip changes or lighter-duty applications.

By understanding the advantages and limitations of both methods, you can choose the right attachment method for your specific needs, ensuring better tool performance and longer service life.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.