أجزاء تآكل كربيد التنغستن are the hidden champions of heavy industry. They make mining drills cut deeper, oilfield tools last longer, and machine components resist wear under extreme conditions.

But for most decision-makers, the production process behind these powerful parts is less visible.

Understanding how tungsten carbide wear parts are made is not only interesting—it also helps companies make smarter choices.

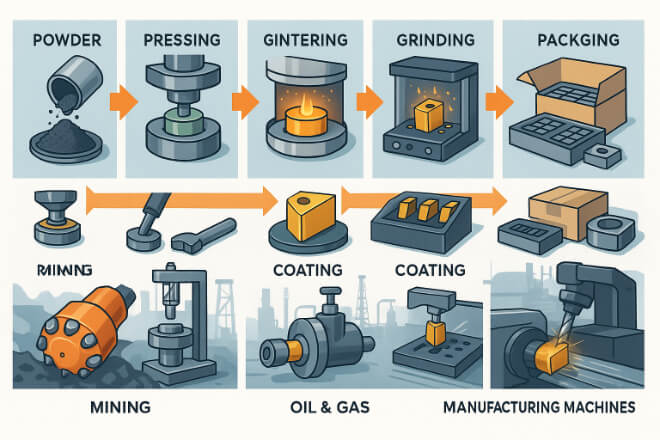

Production steps such as powder preparation, pressing, sintering, grinding, and quality control define the final performance, cost, and reliability.

In this article, we take you behind the scenes of tungsten carbide wear parts production, showing every step from raw materials to finished components.

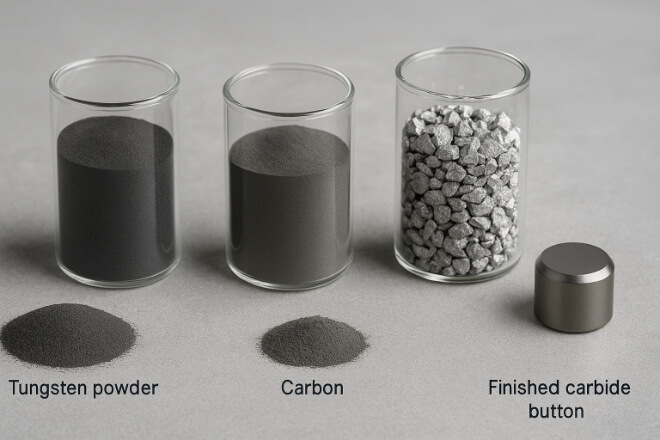

Raw Materials: Tungsten, Carbon, and Binder

The journey starts with powders. Tungsten and carbon are combined to create tungsten carbide (WC).

Fine powders ensure uniformity and high hardness. A metallic binder, usually cobalt or nickel, is mixed in to add toughness and bonding strength.

مسحوق كربيد التنغستن provides hardness.

Binder ensures صلابة and crack resistance.

Additives (such as chromium or vanadium carbides) improve corrosion and grain growth control.

At this early stage, the quality of powders determines the quality of the final product. Reliable sourcing and clean raw materials are critical.

Powder Preparation and Mixing

Next, powders are blended to create the correct recipe for each application. Mining tools, pump seals, and cutting inserts may all need different grades.

Powder preparation involves:

Ball milling: Powders are mixed with binding agents and solvents.

Spray drying: The mixture is dried into uniform granules ready for pressing.

Uniformity is key. If the mix is uneven, some parts of the component will be weak, leading to premature failure in service.

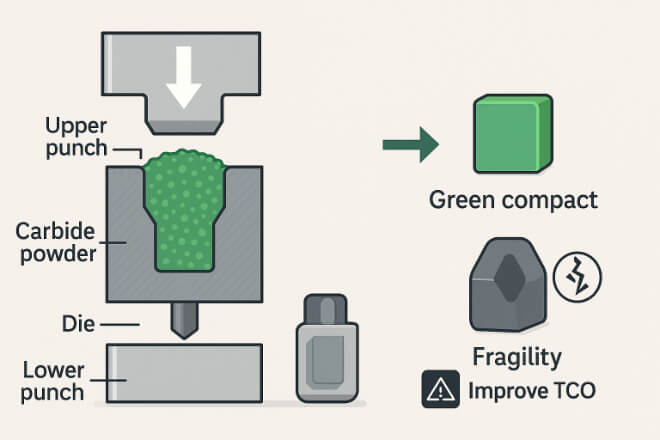

Pressing and Forming

The prepared powder is pressed into a “green compact” (an unsintered shape). There are several forming methods:

Uniaxial pressing: Simple shapes like buttons and inserts.

Cold isostatic pressing (CIP): Large or complex parts, compacted evenly from all sides.

Extrusion and molding: Special shapes such as فوهات أو rods.

At this stage, the part has its rough dimensions but is still fragile, like chalk. Careful handling is required before sintering.

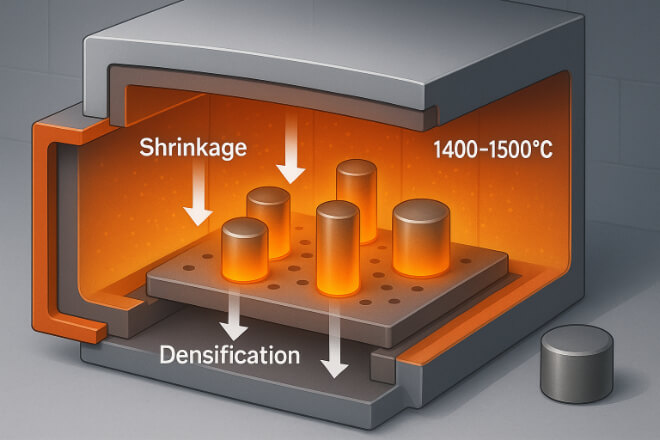

Sintering: The Transformation Stage

Sintering is where tungsten carbide becomes strong. Green compacts are placed in a furnace at around 1400–1500°C.

The binder melts, bonding the carbide grains together. The part shrinks by 20–25% but becomes dense and hard.

Sometimes, hot isostatic pressing (HIP) is added, using gas pressure at high temperature to remove porosity and increase strength.

The sintering stage defines:

It is the most important step for ensuring consistent wear resistance.

Machining and Grinding

After sintering, tungsten carbide parts are extremely hard—close to diamond. This makes machining difficult, but precision finishing is essential.

Diamond grinding wheels are used to shape and size parts.

Centerless grinding ensures uniform roundness for balls and bushings.

Lapping and polishing achieve mirror-like finishes for seals and precision components.

Without precision grinding, even the hardest material cannot perform.

Accurate dimensions and smooth surfaces reduce friction, improve sealing, and extend service life.

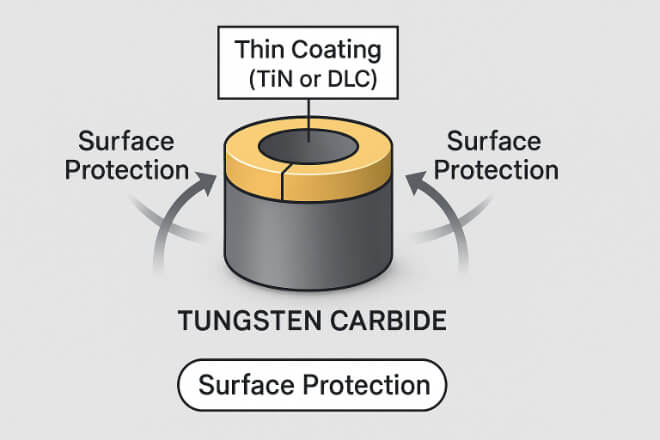

الطلاءات والمعالجات السطحية

In many applications, coatings add another layer of protection. Thin-film coatings improve مقاومة التآكل, reduce friction, or prevent corrosion.

CVD and PVD coatings (e.g., TiN, TiCN, AlTiN).

Diamond-like coatings (DLC) for very low friction.

Nickel plating or other barriers for corrosive environments.

Choosing whether to coat—and with what—depends on the service conditions of the wear part.

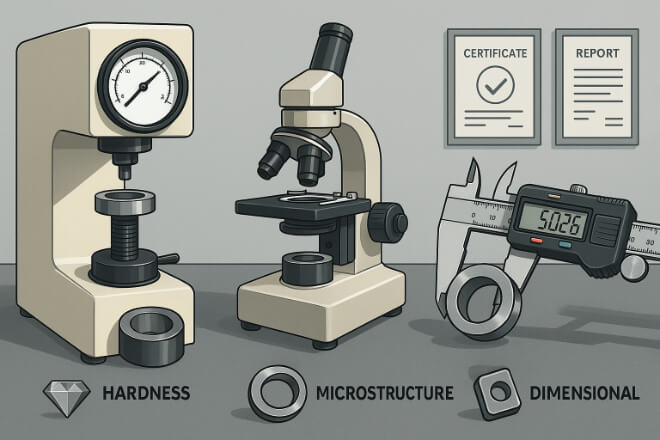

Inspection and Quality Control

No tungsten carbide wear part leaves the factory without testing. Quality control ensures reliability and reduces the risk of failure in the field.

صلابة testing: Using Rockwell or Vickers scales.

Dimensional inspection: Using precision gauges.

Microstructure analysis: To verify grain size and binder distribution.

Certificates and traceability documents are often provided for industrial customers. This builds trust and supports long-term supply agreements.

Packaging and Logistics

Even the toughest wear parts need care when shipped. Packaging includes:

Protective trays or tubes to avoid edge chipping.

Desiccants to prevent corrosion during storage.

Labels with batch numbers and test reports for traceability.

Good logistics ensure parts reach customers safely and ready to install.

From Production to Application

Behind each finished part is a controlled chain of steps: raw materials, mixing, pressing, sintering, grinding, coating, inspection, and shipping. Each step adds value and defines performance.

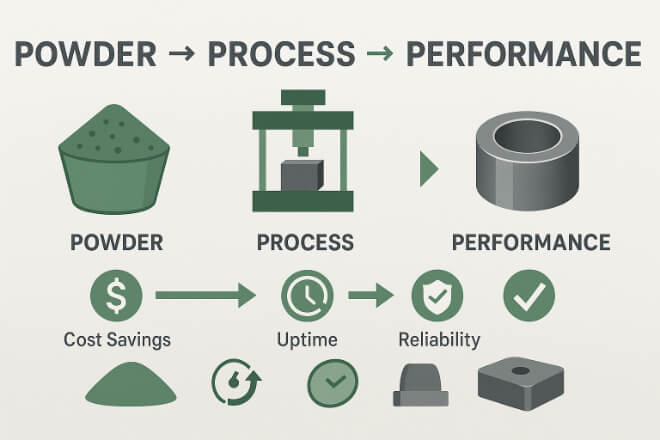

For decision-makers, this behind-the-scenes process matters. The more controlled and consistent the production, the more reliable the wear part in service.

Choosing suppliers with advanced production and strict QC means fewer breakdowns, lower downtime, and better return on investment.

أهم النقاط لصناع القرار

Powder quality defines the foundation of wear part performance.

Mixing, pressing, and sintering steps decide hardness and toughness.

Grinding and finishing ensure precision and long service life.

Coatings can extend protection in demanding environments.

Reliable quality control and logistics secure trust and reduce risk.

خاتمة

Tungsten carbide wear parts are not just hard materials—they are the result of a carefully managed production process.

Each step, from powders to packaging, has a direct impact on how the part performs in mining, oil & gas, construction, or manufacturing.

For companies making high-value decisions, understanding what happens behind the scenes helps in choosing the right supplier, negotiating smarter, and ensuring long-term reliability.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.