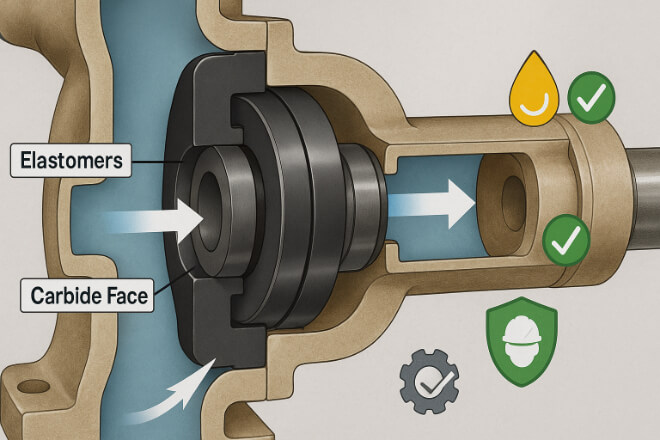

In industrial sealing applications, carbide faces are often paired with elastomers to form reliable seals for pumps, الصمامات, and compressors.

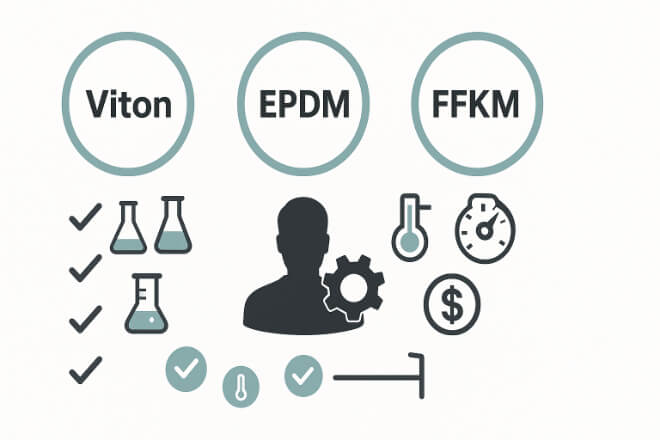

Elastomers such as Viton, EPDM, and FFKM offer flexibility, durability, and resistance to various environmental factors.

The choice of elastomer plays a crucial role in the performance, longevity, and safety of the sealing system.

This guide compares Viton, EPDM, and FFKM elastomers, helping decision-makers choose the best material for their specific needs.

We will discuss their properties, advantages, limitations, and how they pair with carbide faces for optimal sealing performance.

What Are Elastomers and Why Are They Important?

Elastomers are rubber-like materials that can stretch and return to their original shape.

They are essential in sealing applications because of their ability to form tight seals, even under pressure.

When paired with carbide faces, elastomers prevent fluid leakage and protect mechanical components from wear, temperature fluctuations, and chemical exposure.

The right elastomer ensures that the seal remains intact, minimizing maintenance costs and preventing equipment failure.

Types of Elastomers: Viton, EPDM, and FFKM

1). Viton

Viton is a fluoropolymer elastomer known for its outstanding chemical resistance.

1.1). Advantages

Excellent resistance to acids, oils, fuels, and high temperatures.

Good sealing properties at high pressures and temperatures.

Low permeability to gases, making it ideal for high-pressure applications.

1.2). Limitations

Not suitable for low-temperature environments (below -20°C).

Limited performance in water-based applications.

1.3). Best Uses

Pumps in the chemical industry.

Oil & gas معدات.

Fuel systems in high-temperature environments.

2). EPDM (Ethylene Propylene Diene Monomer)

EPDM is a synthetic rubber known for its excellent weathering, ozone, and water resistance.

2.1). Advantages

Good resistance to water, steam, and alkalies.

Performs well in cold environments, with a temperature range of -50°C to +150°C.

Non-polar, making it ideal for water-based fluids.

2.2). Limitations

Not suitable for hydrocarbons or strong acids.

Can degrade when exposed to petroleum-based oils or fuels.

2.3). Best Uses

Water treatment pumps.

Automotive and steam applications.

Cooling systems where exposure to ozone or weathering is a concern.

3). FFKM (Perfluoroelastomer)

FFKM is a high-performance elastomer known for its extreme chemical and temperature resistance.

3.1). Advantages

Exceptional resistance to a wide range of chemicals, acids, and solvents.

Performs well at high temperatures (up to +325°C) and extreme pressures.

Low compression set and excellent sealing capabilities over time.

3.2). Limitations

High cost compared to Viton and EPDM.

Less flexible at lower temperatures than EPDM.

3.3). Best Uses

Pharmaceutical and semiconductor industries.

الفضاء الجوي and high-pressure applications.

Food processing systems where contamination risk is high.

Key Considerations for Choosing the Right Elastomer

When selecting the right elastomer to pair with carbide faces, consider the following factors:

1). Chemical Resistance

Viton is best for environments involving oils, fuels, and chemical compounds.

EPDM excels in water-based systems but is not ideal for hydrocarbons.

FFKM provides the best chemical resistance for aggressive acids, solvents, and harsh chemicals.

2). Temperature Range

Viton handles high temperatures but is less effective at low temperatures.

EPDM is suited for both cold and hot conditions, making it ideal for steam systems.

FFKM can withstand extreme heat, making it the best choice for high-temperature processes.

3). Pressure and Sealing Performance

Viton and FFKM are excellent for high-pressure environments, while EPDM is more suited to lower-pressure systems.

Viton is ideal for gas-tight seals, while FFKM offers the best sealing performance in high-pressure, high-temperature applications.

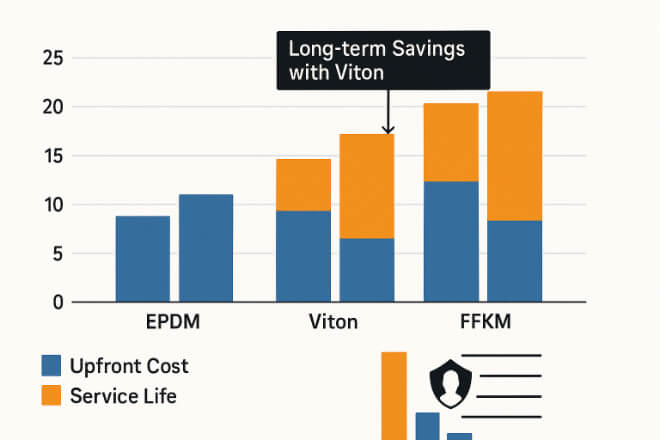

4). Cost Efficiency

Viton offers a good balance between cost and performance for most industrial applications.

EPDM is cost-effective for water-based applications and lower-temperature environments.

FFKM is the most expensive but provides unparalleled performance in critical, high-demand systems.

How Elastomer Selection Impacts Seal Performance

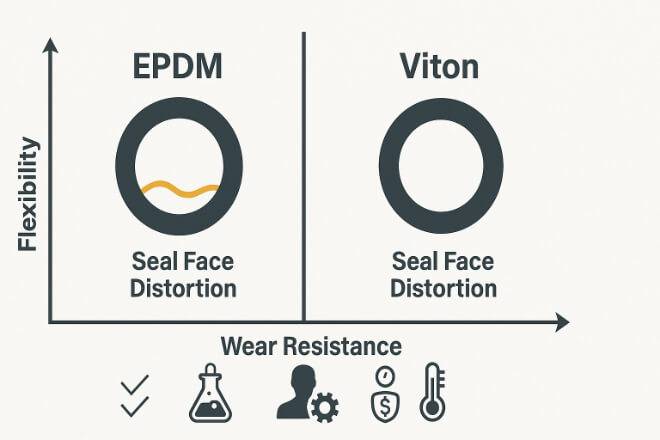

Seal Face Alignment and Wear

The elastomer’s ability to maintain its elasticity under pressure affects how well it mates with the carbide face.

Materials that are too stiff (like FFKM at lower temperatures) might not conform properly, causing leakage or uneven wear.

On the other hand, highly flexible materials (like EPDM) can conform well but may wear faster in harsh conditions.

التوافق الكيميائي

The elastomer’s compatibility with the fluid being sealed is crucial for long-lasting seals.

If the elastomer degrades or reacts with the fluid, it will compromise the seal, causing leakage and contamination.

Best Applications for Viton, EPDM, and FFKM Elastomers

| Elastomer | الأفضل ل | Ideal Environment |

|---|---|---|

| Viton | Oils, fuels, chemicals | High-temperature, aggressive chemical environments |

| EPDM | Water, steam, ozone | Cold and hot environments, outdoor conditions |

| FFKM | High-performance, harsh chemicals | Extreme temperature and pressure conditions |

Maintenance Tips for Elastomers and Carbide Faces

Inspect regularly: Check for wear, cracks, or chemical degradation during planned shutdowns.

Clean seals with appropriate flushing fluids to remove particles or chemicals.

Replace seals proactively when wear is visible to avoid leaks and equipment damage.

Choose compatible elastomers for the fluid type to maximize seal life.

اعتبارات التكلفة والعائد على الاستثمار

Upfront cost: FFKM elastomers are more expensive, but their longevity in high-demand environments justifies the cost.

Savings: Fewer breakdowns and lower maintenance needs reduce long-term operational costs.

ROI: Proper elastomer selection can reduce leak-related downtime and repair costs, improving overall efficiency.

خاتمة

Choosing the right elastomer with carbide faces is crucial for maximizing seal performance, reducing leakage, and increasing operational efficiency.

Understanding the differences between Viton, EPDM, and FFKM allows decision-makers to select the best elastomer for their specific application, ensuring safe, long-lasting seals in pumps, compressors, and valves.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.