Selecting the right clearance fit for بطانات كربيد التنغستن is critical for ensuring the efficiency and longevity of machinery.

The proper fit ensures smooth operation, reduces friction, and minimizes wear.

This blog will guide you through the key considerations when choosing the appropriate clearance fit for tungsten carbide bushings.

Its impact on performance, and how to optimize it for your specific applications.

What is Clearance Fit and Why is it Important for Tungsten Carbide Bushings?

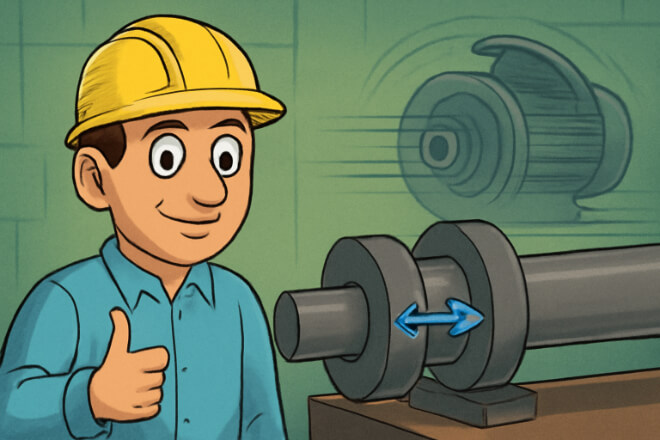

Clearance fit refers to the amount of space between two components, such as a shaft and a bushing, allowing them to move freely without causing interference.

In the case of tungsten carbide bushings, the correct clearance fit is essential for the following reasons:

Prevents Friction and Heat Generation: Proper clearance ensures that the bushing can slide smoothly over the shaft, reducing friction and heat generation.

Minimizes Wear and Tear: An optimal fit helps to reduce unnecessary stress and wear on both the bushing and the shaft.

Ensures Efficient Performance: The right clearance fit guarantees that the bushing functions as intended, providing stability and reducing the risk of damage due to tight or loose fits.

Types of Fits for Tungsten Carbide Bushings

There are three primary types of fits when it comes to installing tungsten carbide bushings: clearance fit, interference fit, and transition fit.

However, the focus here is on clearance fits.

Clearance Fit:

This type of fit provides a gap between the bushing and the shaft, allowing for free movement.

It is typically used in applications where low friction and ease of assembly are required.

Interference Fit:

In an interference fit, the bushing is slightly larger than the shaft, causing them to press tightly together.

This fit is often used when a tight seal or high strength is needed, but it can generate more friction.

Transition Fit:

A transition fit is somewhere between clearance and interference fit, where there might be either a slight gap or a slight interference.

This type of fit is less common but used in applications where both precision and flexibility are necessary.

How to Calculate the Correct Clearance Fit for Tungsten Carbide Bushings

When selecting the clearance fit for tungsten carbide bushings, you must consider several factors such as the shaft diameter, operating temperature, material properties, and tolerances.

Here’s a step-by-step process to help you calculate the ideal clearance fit:

Determine Shaft Dimensions:

Measure the shaft diameter accurately as it is the reference point for selecting the correct bushing.

Account for Thermal Expansion:

Tungsten carbide and the shaft material will expand differently when exposed to heat.

Account for the coefficient of thermal expansion (CTE) for both materials to ensure the fit remains optimal at operational temperatures.

Select Tolerances:

Tolerances define the allowable deviation from the nominal size.

Choosing the right tolerance is critical for ensuring the proper clearance between the shaft and the bushing.

Choose the Right Fit:

Depending on the application, you can select a loose or tight clearance fit. A typical clearance fit for tungsten carbide bushings is between 0.01mm to 0.05mm.

Factors Affecting Clearance Fit Selection

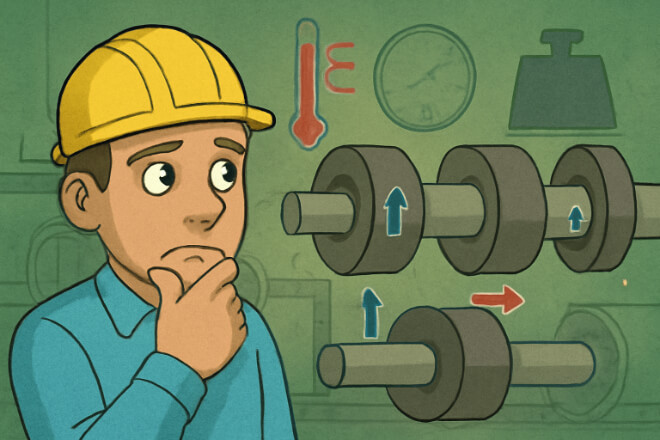

Several factors influence the choice of clearance fit for tungsten carbide bushings:

Operating Conditions:

The load, speed, and environment in which the bushing will operate can significantly affect the required clearance.

High-speed or high-load applications might need a more precise fit to prevent excessive wear.

Temperature Fluctuations:

If the bushing will experience temperature changes, it’s essential to account for thermal expansion to prevent the fit from becoming too tight or too loose.

Material Properties:

Tungsten carbide’s صلابة, brittleness, and مقاومة التآكل are important factors when determining the clearance.

More rigid materials typically require tighter fits to prevent deformation.

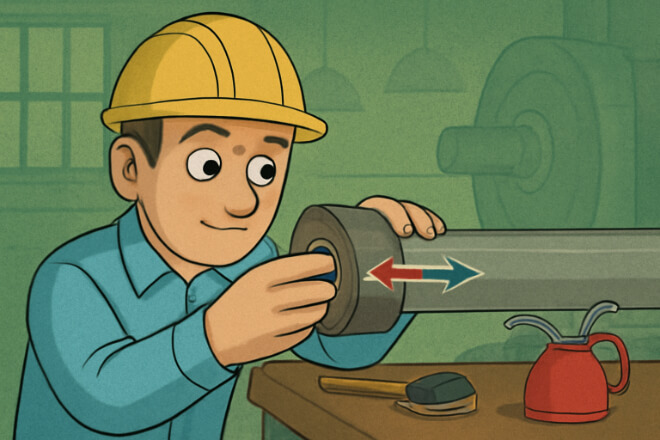

تشحيم:

The presence or absence of lubrication affects the choice of clearance fit. Lubricated bushings may require slightly looser fits for smoother movement.

Tolerance Ranges for Clearance Fits

| Fit Type | Clearance Range (mm) | طلب |

|---|---|---|

| Loose Fit | 0.05–0.10 | Low-speed, low-load applications |

| Medium Fit | 0.01–0.05 | General-purpose use, moderate loads |

| Tight Fit | 0.005–0.01 | High-speed, high-load applications |

Common Mistakes to Avoid When Selecting Clearance Fits

Choosing the wrong clearance fit can lead to performance issues, premature wear, and costly repairs. Here are some common mistakes to avoid:

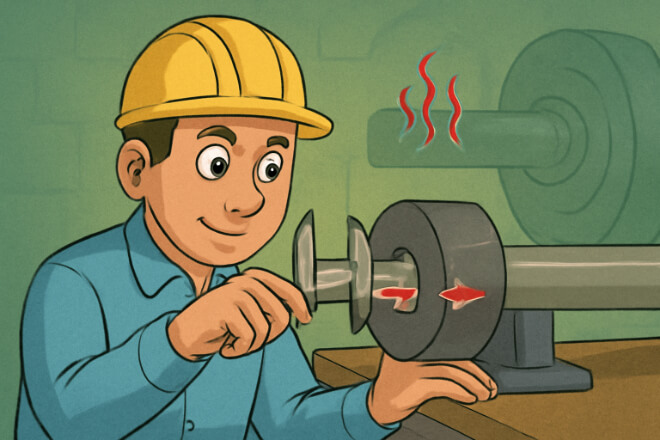

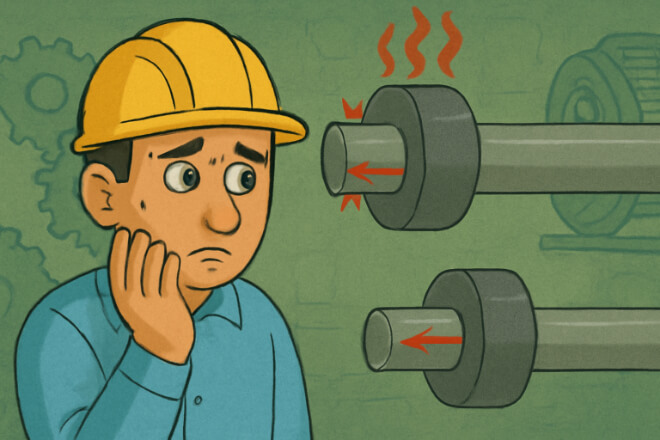

Choosing Too Tight a Fit:

While tight fits may seem like a good idea to ensure stability, they can cause excessive friction and lead to overheating, which damages both the bushing and the shaft.

Ignoring Thermal Expansion:

Failing to account for how materials expand at high temperatures can lead to binding or excessive clearance. Always consider the temperature range in your design.

Overlooking Tolerances:

Tolerances are critical for ensuring that your clearance fit is neither too tight nor too loose.

Inaccurate measurements can lead to unnecessary friction or loose components.

Best Practices for Installing Tungsten Carbide Bushings with Correct Clearance Fit

Proper installation is crucial for ensuring that tungsten carbide bushings perform well in high-stress environments. Follow these best practices:

Clean the Components: Ensure both the shaft and the bushing are clean and free of debris before installation.

Lubricate Properly: Use the right type of lubricant for your application to minimize friction and wear.

Check the Fit Before Use: Before starting the machine, manually check that the bushing fits properly and moves smoothly over the shaft.

Monitor for Wear: Regularly inspect the bushing and shaft for signs of wear. If the fit becomes too tight or loose over time, it may need adjustment.

خاتمة

Selecting the correct clearance fit for tungsten carbide bushings is vital for the smooth operation and longevity of your machinery.

By understanding the different fit types, factors influencing the choice, and best practices for installation, you can ensure that your components perform efficiently under high-stress conditions.

Whether for aerospace, automotive, or industrial machinery, getting the clearance fit right will help reduce downtime and maintenance costs.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.