In industries such as chemical processing, التعدين, النفط والغاز, and power generation, rotating equipment like pumps and compressors must operate continuously.

Every hour of downtime can mean lost production, high repair costs, and safety risks.

Mechanical seals are among the most critical components that determine how long this equipment runs without failure.

And at the heart of these seals are the حلقات ختم الكربيد — precision-engineered components that directly affect sealing life and equipment uptime.

This article explains how carbide seal rings reduce downtime, the mechanisms behind their performance, and real field examples showing their impact on operational efficiency.

لماذا يحدث التوقف في المعدات الدوارة

Downtime often originates from seal failures, not from the main equipment.

A mechanical seal can fail for many reasons — material wear, heat buildup, corrosion, vibration, or improper lubrication.

Here are some of the most common causes:

| Common Cause | Impact on Operation | Seal face wear or scoring | Leakage and reduced sealing efficiency | Thermal cracking | Sudden seal failure and shutdown | Corrosion or chemical attack | Seal material degradation | Vibration and misalignment | Accelerated wear and edge chipping |

|---|

Replacing seals and repairing the pump shaft can take hours or even days, leading to major production losses.

That is why choosing the right seal ring material, like tungsten carbide or silicon carbide, is essential for minimizing downtime.

What Are Carbide Seal Rings?

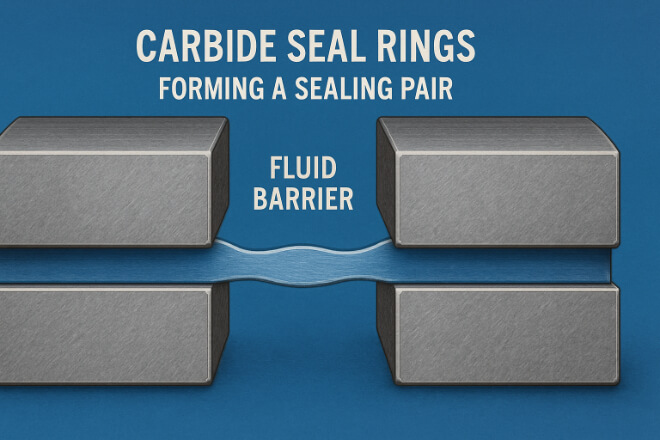

حلقات ختم الكربيد are circular components used in mechanical seals to form a tight barrier between rotating and stationary parts.

They prevent leakage of fluids while maintaining pressure and temperature stability.

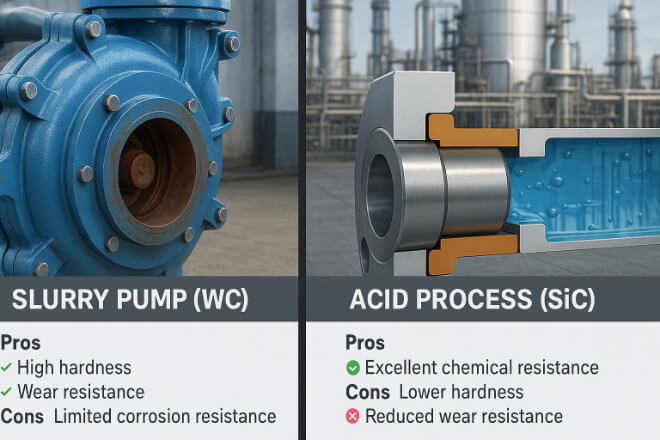

The two most common types are:

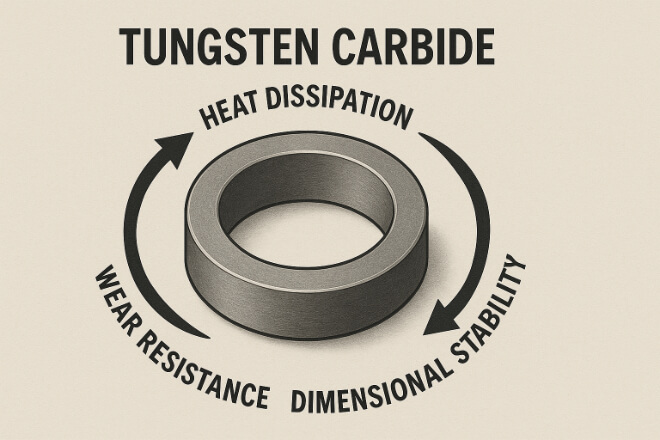

Tungsten carbide seal rings (WC-Co) — extremely hard, tough, and wear-resistant.

Silicon carbide seal rings (SiC) — lighter and more corrosion-resistant but slightly more brittle.

These materials provide a hard, smooth surface that resists abrasion and maintains flatness even under high pressure and temperature.

In most rotating equipment, carbide seal rings are paired with softer counterfaces (like carbon or resin-impregnated graphite) to create a low-friction sealing pair.

How Carbide Seal Rings Reduce Downtime

The main way carbide seal rings reduce downtime is by extending seal life and preventing premature failures.

Below are the key performance mechanisms behind this reliability.

1). Exceptional مقاومة التآكل

Tungsten carbide has a صلابة of around 1600–2000 HV, which allows it to resist abrasion from particles in process fluids.

In applications like slurry pumps or chemical mixers, this means far less face wear and fewer replacements.

2). Excellent Thermal Conductivity

Carbide conducts heat efficiently away from the sealing face, preventing local overheating.

This helps maintain stable running conditions and prevents thermal cracking — a major cause of seal failure.

3). Dimensional Stability Under Load

Even at high rotational speeds and pressures, carbide retains its flatness and shape. Stable geometry means better sealing performance and longer life.

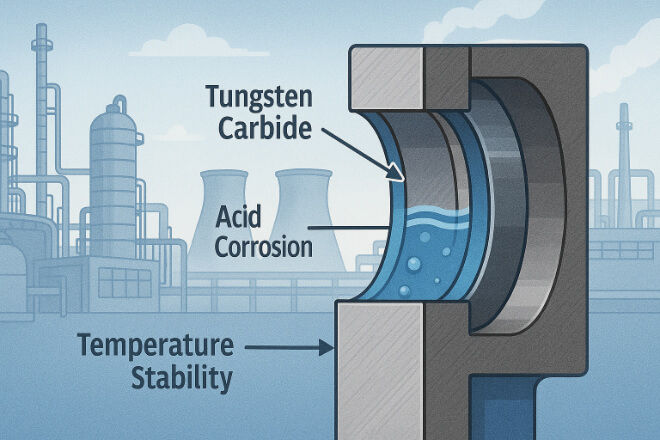

4). Corrosion Resistance in Harsh Media

Special grades of tungsten carbide with nickel binders or silicon carbide can resist corrosion from acids, alkalis, and aggressive fluids — reducing chemical damage and downtime caused by seal leakage.

5). Compatibility With Various Fluids

Carbide seals work across a wide range of fluids — from water and oils to chemical slurries — making them a flexible choice for mixed plant environments.

Comparing Carbide Rings to Other Materials

Let’s compare the durability and performance of carbide seal rings against common alternatives like carbon or ceramic.

| ملكية | Carbon | سيراميك | كربيد التنغستن | صلابة | قليل | واسطة | عالية جدًا | Thermal Shock Resistance | جيد | فقير | ممتاز | مقاومة التآكل | معتدل | جيد | متميز | مقاومة التآكل | ممتاز | جيد | Good (with Ni binder) | Typical Service Life | قصير | معتدل | طويل |

|---|

From the comparison, carbide stands out as the most balanced material — durable, thermally stable, and cost-effective in the long term.

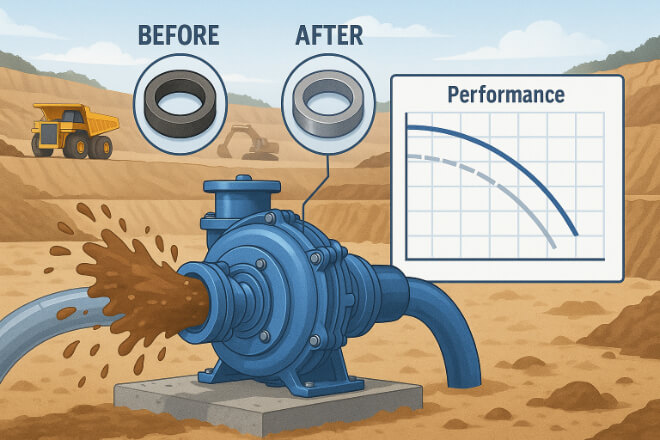

Field Example 1: Slurry Pump in a Mining Operation

A copper mining plant in South America faced severe seal wear due to abrasive slurry. Each pump seal lasted only 3 weeks before leakage began.

After replacing the standard carbon faces with tungsten carbide seal rings, the service life increased to 12 weeks.

This resulted in:

75% reduction in seal replacements

Fewer shutdowns and maintenance hours

Cost savings of over $150,000 annually

The improved مقاومة التآكل of tungsten carbide directly translated into longer uptime and lower maintenance cost.

Field Example 2: Chemical Process Pump

In a chemical plant handling hot acids, ceramic seal rings often failed due to thermal cracking.

After switching to nickel-bonded tungsten carbide rings, the seals lasted four times longer, even under fluctuating temperature cycles.

The plant reported:

No thermal shock failures in 9 months

60% lower seal replacement costs

Improved overall plant reliability

Field Example 3: Power Plant Condensate Pump

A power generation facility used silicon carbide seal rings for condensate pumps operating continuously. Before, seals required replacement every 8 months.

By upgrading to tungsten carbide rings with a precision lapped finish, the service interval extended to over 18 months, cutting planned maintenance frequency by half.

This directly reduced unplanned downtime and increased output reliability.

When to Choose Tungsten Carbide vs. Silicon Carbide

Choosing between tungsten carbide (WC) and silicon carbide (SiC) depends on the working environment. Here’s a simple comparison:

| Application Condition | Recommended Material | Abrasive or particle-laden fluids | كربيد التنغستن | Highly corrosive fluids | Silicon Carbide | High pressure or load | كربيد التنغستن | Thermal cycling or temperature shock | Tungsten Carbide (Ni binder) | Light chemical or clean water service | Either |

|---|

This guidance helps decision-makers match seal materials to operational priorities — durability, مقاومة التآكل, or thermal stability.

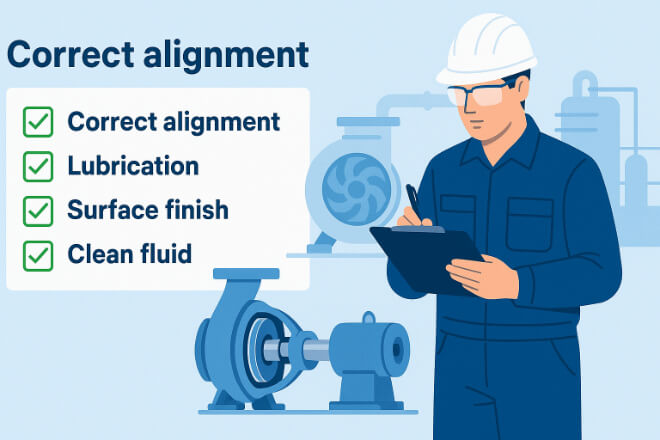

Practical Tips for Maximizing Seal Life

Even with carbide seals, proper installation and handling are vital to achieving maximum uptime:

Ensure flatness and surface finish are within OEM specs (Ra 0.02–0.05 µm).

Avoid dry running; always pre-lubricate seals.

Maintain correct axial alignment and pressure balance.

Implement regular inspection and re-lapping instead of full replacement.

Keep fluid conditions clean and stable to minimize particle impact.

By following these practices, plants can achieve 30–70% longer equipment uptime with carbide seals.

خاتمة

Carbide seal rings — especially those made from tungsten carbide — have become a key solution for minimizing downtime in rotating equipment.

Their superior hardness, wear resistance, and thermal stability make them ideal for demanding applications.

As the field examples show, the investment in high-quality carbide seals quickly pays back through reduced maintenance hours, longer service life, and lower operational risk.

For decision-makers, upgrading to carbide seal technology is not just a technical improvement — it’s a strategic move toward greater reliability and productivity.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.