اختيار الصحيح tungsten carbide bushing supplier is one of the most important decisions for any manufacturer or plant operator.

The quality of your bushings directly affects machine life, downtime, and maintenance cost.

A reliable supplier is not just a vendor — it’s a long-term partner that helps you achieve consistent performance, cost control, and supply stability.

This article explains what to look for in a tungsten carbide bushing supplier, how to evaluate their technical and production capabilities, and what signs show a supplier can truly be trusted.

Why Supplier Selection Matters

Bushings made from tungsten carbide are used in pumps, compressors, turbines, and drilling tools. They operate under extreme pressure, friction, and temperature.

A poor-quality supplier might cut corners — using low-grade powder or poor sintering techniques — resulting in parts that fail early.

On the other hand, a trusted supplier ensures that each bushing meets exact specifications, reducing failure risk and saving long-term costs.

A good supplier also provides:

Stable material consistency

Traceable production data

Precision machining and testing

Fast delivery with after-sales support

The right partnership builds reliability into your entire operation.

Check Raw Material Control

The foundation of every tungsten carbide bushing is the powder composition.

Suppliers must use high-purity مسحوق كربيد التنغستن and quality cobalt or nickel binders.

The ratio of WC to binder determines صلابة, صلابة، و مقاومة التآكل.

| نوع المجلد | Typical Composition | Key Advantage | أفضل تطبيق |

|---|---|---|---|

| رابط الكوبالت | 6–12% Co | High strength, balanced wear resistance | General industry, rotating equipment |

| رابط النيكل | 8–15% Ni | Superior corrosion resistance | Chemical, marine, and oil & gas services |

Ask your supplier for:

Material certificates for each batch

Powder origin and binder ratio details

Consistency records from the mixing process

Reliable suppliers will provide this without hesitation.

Evaluate Manufacturing Capabilities

A good tungsten carbide supplier must have strong control over all critical stages — from pressing to sintering and grinding.

Key manufacturing checkpoints:

Powder mixing uniformity

Vacuum sintering furnace control (temperature and pressure)

CNC grinding precision to ±0.002 mm

Surface finishing up to Ra 0.05 µm

Suppliers that own in-house facilities (rather than outsourcing) ensure consistent quality.

Ask for a factory tour or production video — it often reveals their true capability level.

Quality Control and Testing

Quality assurance is more than a final inspection. It’s a process that runs from raw materials to the finished part.

A reliable supplier should perform:

| Test Type | غاية | Frequency |

|---|---|---|

| الصلابة (HRA) | Ensures correct sintering and strength | Every batch |

| CMM Dimensional Check | Verifies tight tolerance (±0.002 mm) | Each production lot |

| Surface Roughness (Ra) | Confirms lapping quality and smoothness | Every piece |

Consistency in testing means predictable results in the field — the most valuable form of reliability.

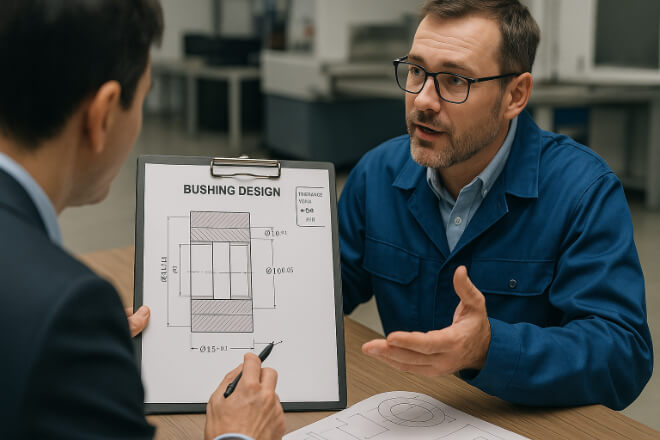

Technical Support and Engineering Service

Top suppliers don’t just sell products — they help engineers choose the right grade and geometry.

Look for suppliers who can:

Recommend optimal binder types for your working medium

Advise on fit tolerance between bushing and shaft

Provide CAD drawings and tolerance documentation

Offer failure analysis reports when wear issues arise

Technical expertise shows that the supplier understands not just the material, but your real-world application.

Traceability and Certification

في الصناعات مثل النفط والغاز, chemical, and power generation, traceability is a must. Your supplier should provide:

Batch numbers and heat treatment records

Material trace certificates (EN10204 3.1)

Compliance with ISO 9001 or equivalent

This ensures that if any issue occurs, you can track every step back to production — essential for reliability and audit compliance.

Lead Time, Delivery, and Supply Stability

Fast response and delivery are crucial in industrial operations. Delays in spare parts can lead to expensive downtime.

Reliable suppliers:

Maintain standard-size bushings in stock

Provide realistic lead times for custom parts

Offer priority manufacturing for repeat clients

Use secure packaging to prevent transit damage

Steady communication and predictable timelines reflect professional management and reliability.

التكلفة مقابل القيمة

While price is always a factor, it should never be the only one. A low-cost supplier may offer short-term savings but cause long-term losses if products fail prematurely.

You should evaluate total cost of ownership (TCO) — considering lifespan, downtime prevention, and replacement frequency.

| Supplier Type | التكلفة الأولية | Product Life | Total Cost of Ownership |

|---|---|---|---|

| Low-Cost / Trader | قليل | قصير | High (frequent replacements) |

| Verified Manufacturer | معتدل | طويل | Low (stable performance) |

Choose suppliers who focus on lifecycle value, not just the lowest price tag.

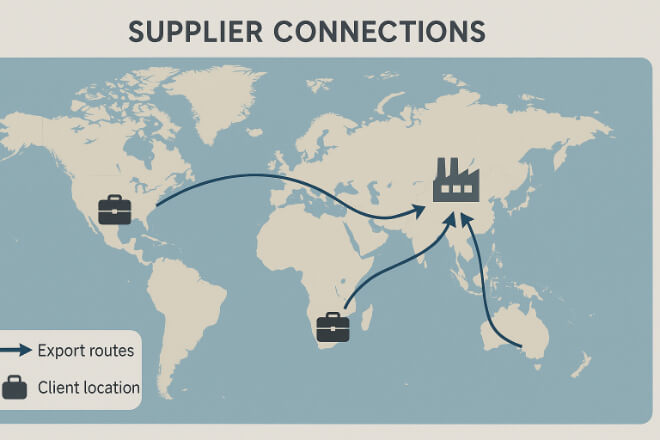

Reputation and Global References

Reputation is earned through consistent performance.

Look for suppliers who:

Have export experience to major industrial regions

Provide case studies or reference clients

Have a strong online presence with detailed technical content

Are recognized by international companies

Checking reviews, certificates, and long-term client relationships helps you gauge real reliability — not just marketing claims.

خاتمة

Selecting a tungsten carbide bushing supplier is not only about finding the lowest price — it’s about finding a partner who can guarantee consistent quality, stable supply, and technical expertise.

Reliable suppliers control every production stage, test each part thoroughly, and provide documentation that ensures peace of mind.

With the right partner, you’ll gain longer service life, lower downtime, and a better return on investment for your machinery.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.