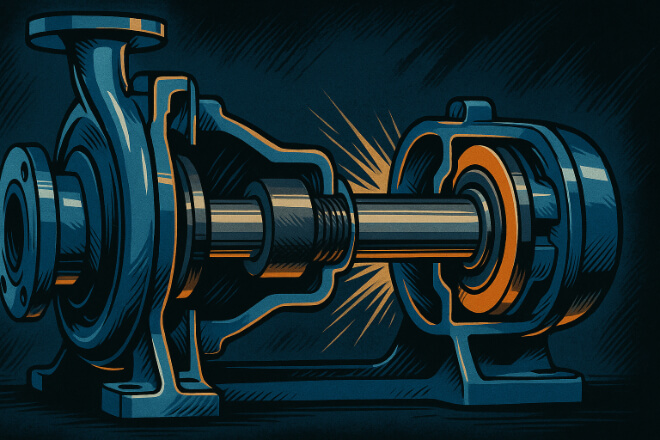

Tungsten carbide bushings are crucial components in industrial applications, providing wear resistance and durability in harsh environments.

Pairing them with the right mechanical seals is essential for ensuring system reliability and preventing leakage.

Upgrading mechanical seals can significantly enhance the performance of tungsten carbide bushings, leading to longer operational lifespans and reduced maintenance costs.

This article explores how to successfully pair tungsten carbide bushings with mechanical seal upgrades for optimal performance.

Understanding the Role of Tungsten Carbide Bushings and Mechanical Seals

Before diving into pairing strategies, it’s important to understand the individual roles of tungsten carbide bushings and mechanical seals in industrial systems.

1). Tungsten Carbide Bushings:

Durability: Tungsten carbide is known for its exceptional wear resistance, especially in applications with high speeds and pressure.

Lubrication: These bushings help reduce friction and wear by acting as a bearing surface for shafts.

مقاومة التآكل: Tungsten carbide is highly resistant to corrosion, making it ideal for harsh environments, including those with high temperatures or aggressive fluids.

2. Mechanical Seals:

Leak Prevention: Mechanical seals prevent fluid leakage by creating a seal between rotating and stationary parts, ensuring that the system remains airtight and fluid-tight.

Enhanced Performance: Mechanical seals reduce friction and wear between moving parts, improving the efficiency of systems like pumps and compressors.

Customization: Mechanical seals are available in a variety of materials and designs, allowing them to be tailored to specific applications.

How Mechanical Seal Upgrades Enhance Tungsten Carbide Bushing Performance

Upgrading mechanical seals can provide several benefits when paired with tungsten carbide bushings, leading to improved system efficiency and reduced maintenance.

Key Benefits of Upgrading Mechanical Seals:

Increased Sealing Efficiency: High-performance mechanical seals, such as dual seals or non-contacting seals, provide a more reliable seal, preventing leakage and reducing contamination risk.

Reduced Wear on Bushings: Upgraded seals help reduce friction between the bushing and the shaft, decreasing the wear on tungsten carbide bushings and extending their lifespan.

Improved Operational Reliability: Mechanical seal upgrades enhance system performance by maintaining a stable operating environment, preventing overheating, or fluid contamination, which can damage the bushings.

Enhanced Protection Against Aggressive Fluids: Certain mechanical seals are designed to handle harsh chemicals or high temperatures, providing better protection for both the bushing and the equipment.

How to Choose the Right Mechanical Seal for Your Tungsten Carbide Bushing

Selecting the right mechanical seal for your tungsten carbide bushing is key to achieving optimal performance. Factors such as material compatibility, operating conditions, and seal design must be considered.

Factors to Consider:

Operating Conditions:

Determine the temperature, pressure, and chemical composition of the fluids the system will handle. Choose mechanical seals that can withstand these conditions while maintaining performance.

Seal Material Compatibility:

Ensure the material of the mechanical seal is compatible with the tungsten carbide bushing.

Materials like silicon carbide or ceramic are commonly paired with tungsten carbide bushings for superior مقاومة التآكل.

Seal Type:

Different seal types, such as single seals, double seals, or pusher seals, offer varying levels of protection and efficiency.

The choice will depend on the specific application and the environment in which the bushing operates.

System Design:

The mechanical seal must match the geometry and size of the bushing and shaft to ensure a proper fit. Incorrect installation can lead to misalignment, increased friction, and premature failure.

Best Practices for Pairing Tungsten Carbide Bushings with Mechanical Seals

Proper installation and maintenance are crucial for achieving the benefits of pairing tungsten carbide bushings with mechanical seal upgrades. Follow these best practices to ensure long-lasting performance.

Best Practices for Pairing:

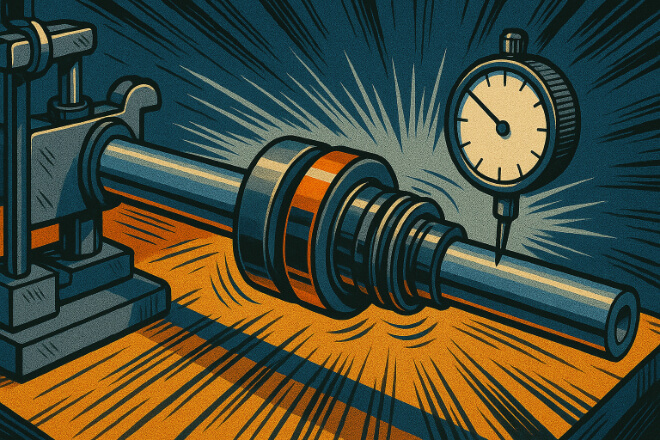

Proper Installation:

Ensure that both the tungsten carbide bushing and the mechanical seal are installed according to manufacturer guidelines. Incorrect installation can cause misalignment and premature wear.

عمليات التفتيش الدورية:

Periodically inspect both the bushing and seal for signs of wear, misalignment, or leakage. Regular maintenance will help detect issues early and prevent costly repairs.

Use Compatible Materials:

When upgrading mechanical seals, ensure that the materials used are compatible with both the bushing and the fluid being handled. Incompatible materials can lead to wear, corrosion, or leakage.

Monitor Operating Conditions:

Keep track of operational parameters such as temperature, pressure, and speed. Adjust system settings to ensure that both the bushing and seal operate within the recommended limits.

تشحيم:

Ensure that proper lubrication is maintained between the tungsten carbide bushing and the shaft. Lubrication reduces friction, which can help extend both the seal and bushing’s lifespan.

Common Issues When Pairing Tungsten Carbide Bushings with Mechanical Seals

While pairing tungsten carbide bushings with mechanical seals provides many benefits, certain challenges can arise if not done correctly.

Common Issues to Watch for:

Misalignment: Misalignment between the bushing and mechanical seal can cause uneven wear, leading to failure.

Improper Fit: If the seal does not fit the bushing and shaft properly, it can lead to leakage and wear.

Incompatible Materials: Using incompatible materials for the bushing and seal can lead to early failure. Ensure both components are made from materials that are compatible with each other and the system’s fluids.

Excessive Pressure: High operating pressures can exceed the mechanical seal’s limits, causing failure and damaging both the seal and bushing.

Lack of Lubrication: Insufficient lubrication can cause both the bushing and seal to wear out faster, reducing their lifespan and effectiveness.

خاتمة

Pairing tungsten carbide bushings with the right mechanical seal upgrades is essential for improving system performance, extending component lifespan, and preventing failures.

By carefully selecting the appropriate seal material, type, and design based on your operational needs, and following best practices for installation and maintenance, you can significantly enhance the efficiency and reliability of your equipment.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.