Tungsten carbide bushings are widely used in industries that require exceptional مقاومة التآكل, durability, and صلابة.

These bushings play a critical role in high-performance machinery, from pumps to heavy equipment.

However, one common challenge during installation is the risk of cracking the bushing during the press-fit process.

This blog will explore how to press-fit tungsten carbide bushings properly, minimizing the risk of cracking and ensuring long-lasting performance.

What is Press-Fitting?

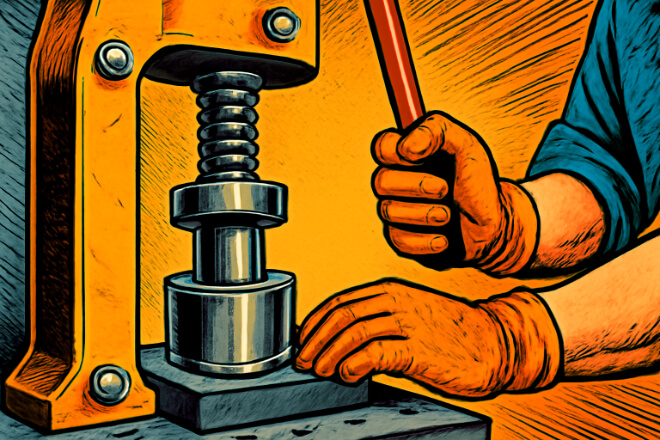

Press-fitting is a method of installing a component, such as a bushing, into a housing or bore by applying a force that presses the part into place.

The fit is typically tight enough to create a frictional bond that holds the bushing in place without the need for fasteners.

Types of Press Fits: There are different types of press fits, such as interference fits and transition fits, each suited for different levels of force and clearance between the bushing and the housing.

While press-fitting is an efficient way to install bushings, it can put significant stress on brittle materials like tungsten carbide, which increases the risk of cracking if not done correctly.

Why Tungsten Carbide Bushings are Prone to Cracking

Tungsten carbide is known for its صلابة, but it is also a relatively brittle material.

Unlike softer metals, it can crack or fracture when subjected to excessive stress or improper installation methods.

The primary reasons tungsten carbide bushings crack during press-fitting include:

Excessive Force: Applying too much force during installation can cause the bushing to crack.

Improper Alignment: If the bushing is misaligned with the housing or bore, uneven pressure can cause stress concentrations, leading to cracks.

Temperature Fluctuations: Extreme temperature differences between the bushing and housing can increase the risk of cracking.

Poor Fit Tolerances: If the fit between the bushing and the housing is too tight, the bushing may experience stress that leads to cracking.

Steps to Prevent Cracking When Press-Fitting Tungsten Carbide Bushings

To ensure that tungsten carbide bushings are press-fitted without cracking, follow these essential steps:

1). Select the Right Fit

The first step in preventing cracking is to choose the correct fit between the bushing and the housing. The fit should not be too tight, as this can increase the risk of stress during installation.

Interference Fit: For critical applications where a strong bond is needed, use an interference fit, but make sure the fit is not excessively tight.

Transition Fit: A transition fit offers a balance between an interference fit and a clearance fit. It’s a safer option when working with brittle materials like tungsten carbide.

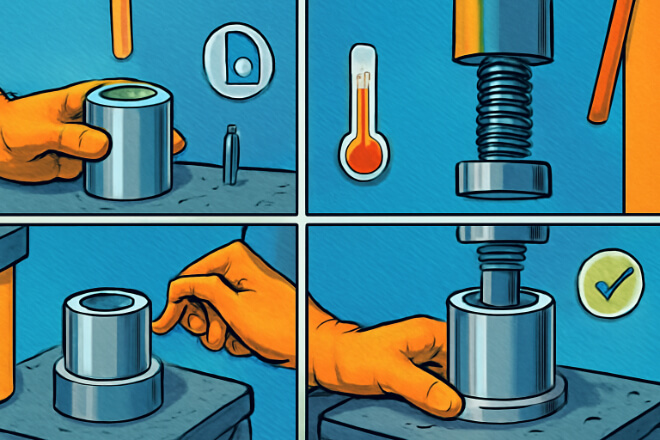

2). Use Proper Alignment Techniques

Misalignment during the press-fit process can cause uneven stress, leading to cracks.

Always ensure that the bushing and housing are properly aligned before pressing. Here are a few tips:

Check Alignment: Use an alignment tool or jig to ensure that the bushing is aligned correctly with the housing or bore before pressing.

Apply Pressure Evenly: Use a press machine that applies pressure uniformly across the bushing to prevent localized stress concentrations.

3). Control the Temperature

Temperature control is another key factor in preventing cracking.

Tungsten carbide can expand or contract significantly depending on the temperature, and temperature differences between the bushing and housing can cause cracking.

Warm the Bushing: Before pressing, heat the tungsten carbide bushing slightly (but not excessively) to reduce the risk of thermal shock. This can help expand the bushing slightly for a smoother press fit.

Cool the Housing: Cooling the housing or bore can also help create a proper fit by allowing it to contract, making the fit easier without applying excessive force.

4). Apply Lubrication

Lubrication helps reduce friction during the press-fit process, lowering the force required to install the bushing and preventing unnecessary stress.

Use Proper Lubricants: Apply an appropriate lubricant that is compatible with tungsten carbide and the material of the housing. This will reduce friction and make the installation process smoother.

Lubrication Placement: Apply lubricant on both the bushing and the housing bore to ensure even distribution of pressure and minimize the risk of cracking.

5). Gradually Apply Pressure

Instead of applying all the force at once, gradually increase the pressure during the press-fitting process.

This allows the bushing to fit smoothly into place without sudden stress that could cause cracking.

Manual vs. Machine Pressing: If using a manual press, apply pressure slowly and ensure there are no sudden movements. Automated presses can help ensure a consistent application of pressure.

Measuring the Fit and Tolerances

Before press-fitting a tungsten carbide bushing, it’s important to measure the fit and tolerances to ensure that the dimensions are correct. The following measurements should be taken:

Outer Diameter of the Bushing: Measure the diameter of the bushing to ensure it matches the housing’s inner diameter.

Housing Diameter: Measure the bore diameter to confirm it is appropriate for the bushing.

Interference or Transition: Calculate the amount of interference (if any) between the bushing and housing. This should be within acceptable limits to avoid excessive stress.

Common Tolerances for Tungsten Carbide Bushings

| Tolerance Type | Recommended Range | Importance |

|---|---|---|

| Outer Diameter of Bushing | ±0.005 to ±0.020 mm | Ensures proper fit with housing |

| قطر التجويف | ±0.005 to ±0.020 mm | Prevents over-pressing or under-pressing |

| Interference Fit | 0.002 to 0.005 mm | Minimizes stress during press-fit |

The Importance of Press-Fit Quality Control

Quality control is essential when press-fitting tungsten carbide bushings to prevent cracks and ensure reliable performance. Here are some key quality control steps:

Check for Cracks: Before installation, inspect the bushing for any visible cracks or defects. Even minor cracks can compromise the bushing’s performance.

Verify Press-Fit Dimensions: Double-check the tolerance and dimensions to make sure the press fit is within acceptable limits.

Post-Installation Inspection: After press-fitting, inspect the assembly to ensure that the bushing is securely in place and there are no signs of damage or stress.

خاتمة

Press-fitting tungsten carbide bushings without cracking requires careful attention to fit, alignment, temperature control, lubrication, and pressure application.

By following best practices for press-fit installation, manufacturers can ensure the longevity and performance of their tungsten carbide bushings in demanding applications.

Proper quality control and precision machining will help prevent cracking and maintain the integrity of the components.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.