تشتهر أدوات القطع المصنوعة من كربيد التنغستن بصلابتها وعمرها الطويل. ولكن مع الاستخدام المكثف، حتى أفضل أدوات الكربيد قد تصبح باهتة أو مهترئة. بدلاً من التخلص منها، يمكن شحذ العديد منها وتجديدها لاستعادة أدائها في القطع.

في هذا الدليل، سنشرح خطوة بخطوة، بلغة إنجليزية مبسطة، كيفية شحذ أدوات القطع المصنوعة من كربيد التنغستن وتجديدها. ستتعلم أيضًا كيفية تحديد وقت الشحذ المناسب، وكيفية اختيار الطريقة والمعدات المناسبة.

لماذا يجب تجديد أدوات كربيد التنغستن؟

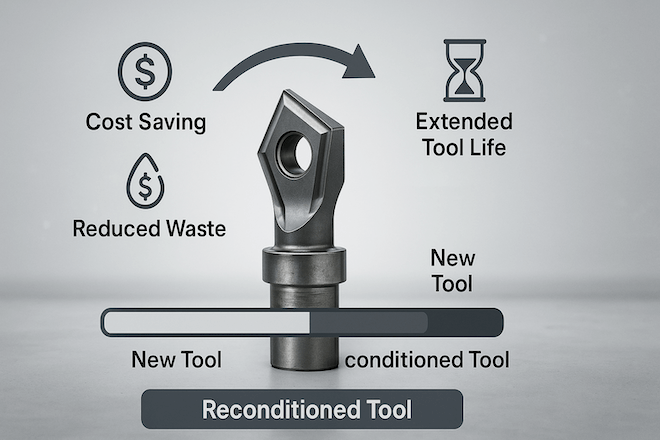

أدوات كربيد التنغستن أغلى من أدوات الفولاذ العادية. لذلك، يُعدّ شحذها وإعادة استخدامها خيارًا تجاريًا مربحًا. تساعدك إعادة تأهيلها على:

وفر المال على البدائل

الحفاظ على هندسة الأداة ودقتها

تقليل وقت التوقف في الإنتاج

تقليل النفايات ودعم الاستدامة

تقدم ريتوب مجموعة كاملة من أدوات القطع المصنوعة من الكربيد، مع دعم لخدمات إعادة الشحذ والطحن. يمكنك استكشاف المزيد هنا: أدوات القطع المصنوعة من كربيد التنغستن.

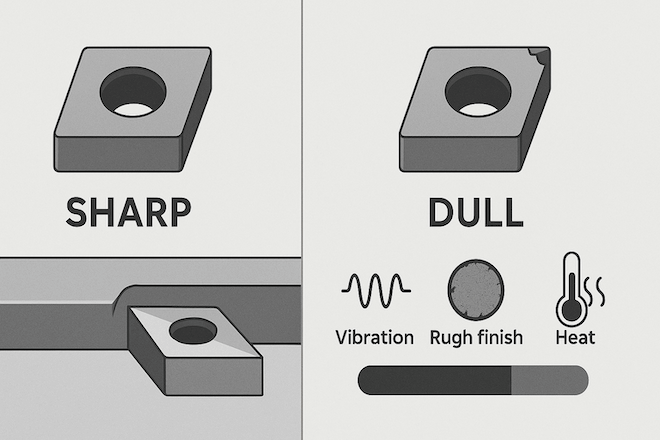

علامات شائعة تشير إلى أن أداة الكربيد الخاصة بك بحاجة إلى شحذ

لست متأكدًا من متى يجب إعادة الشحذ؟ ابحث عن هذه العلامات:

حافة القطع الباهتة

الثرثرة أو الاهتزاز أثناء التشغيل

سوء تشطيب السطح على قطعة العمل

زيادة قوة القطع أو ضغط الأداة

تآكل واضح على جوانب الأداة أو زواياها

قد يؤدي استخدام أداة غير حادة لفترة طويلة إلى ارتفاع درجة حرارتها أو كسرها أو حدوث عيوب في أجزائها.

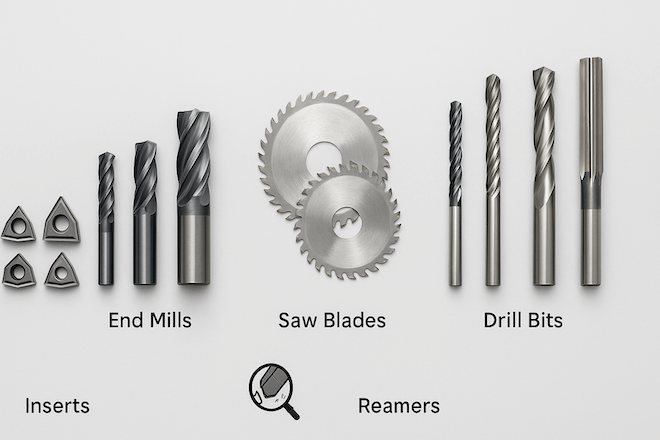

أنواع أدوات كربيد التنغستن التي يمكن تجديدها

يمكن تجديد العديد من أنواع أدوات الكربيد إذا لم تكن مكسورة بشكل سيء للغاية:

أدوات كربيد مخصصة

استكشف كتالوجنا الكامل هنا:

👉 أدوات قطع كربيد مخصصة

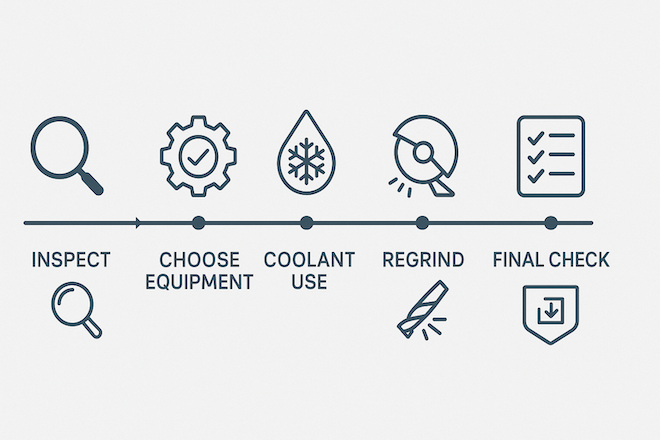

خطوة بخطوة: كيفية شحذ أدوات القطع المصنوعة من كربيد التنجستن

1. افحص الأداة بعناية

قبل الشحذ، افحص الأداة تحت ضوء ساطع أو عدسة مكبرة. تحقق من:

علامات التآكل

الشقوق

رقائق البطاطس

حواف مكسورة

قد لا يكون من المفيد شحذ الأدوات التالفة بشدة.

2. اختر معدات الشحذ المناسبة

يتطلب شحذ كربيد التنغستن استخدام مواد كاشطة ماسية أو عجلات CBN. عجلات الطحن العادية لا تُجدي نفعًا.

تشمل الآلات والأدوات الشائعة ما يلي:

آلة طحن الأدوات CNC

آلة طحن الأسطح الدقيقة

أداة عالمية وقاطعة ومطحنة

عجلات طحن الماس (راتنج أو رابطة زجاجية)

بالنسبة للأدوات المعقدة أو الأدوات المطلية، يوصى بالخدمة المهنية.

3. استخدم سائل التبريد أو التشحيم

يُولّد الطحن حرارةً قد تُتلف الكربيد. استخدم دائمًا:

سائل تبريد قابل للذوبان في الماء أو

سائل تبريد قائم على الزيت

يساعد هذا على تقليل الشقوق الحرارية ويحافظ على صلابة الأداة.

4. إعادة صقل الحافة القاطعة

اتبع الهندسة الأصلية عند إعادة الطحن. تشمل الأجزاء الرئيسية التي يجب إعادة طحنها ما يلي:

زوايا الخلوص الأولية والثانوية

زوايا أشعل النار

حواف المزمار (للمثاقب والقواطع الطرفية)

نصف قطر الزاوية أو الحافة

استخدم عجلات الماس ذات الحبيبات الدقيقة للحصول على حافة ناعمة وحادة.

5. نظف وافحص مرة أخرى

بعد الشحذ:

تنظيف الأداة

التحقق من وجود شقوق على السطح

اختبار أداء القطع إذا كان ذلك ممكنا

إذا كان لديك طلاء (مثل TiAlN أو TiCN)، فقد تحتاج إلى إعادة طلاء الأداة بعد الشحذ.

تعرف على المزيد حول الطلاءات هنا:

👉 دليل طلاء كربيد التنغستن

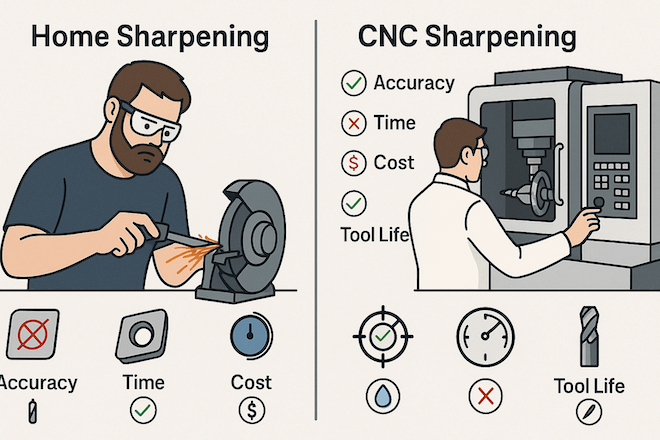

الشحذ بنفسك مقابل الشحذ الاحترافي: أيهما أفضل؟

| عامل | شحذ افعلها بنفسك | خدمة احترافية |

|---|---|---|

| يكلف | أقل إذا كانت الأدوات قليلة | أكثر فعالية من حيث التكلفة للدفعات |

| دقة | يعتمد على المهارة والمعدات | دقة عالية |

| وقت | مضيعة للوقت | تحول أسرع |

| معالجة الطلاء | غير ممكن في المنزل | يمكن إزالة الطلاءات وإعادة تطبيقها |

| أداة الحياة | قد يقصر مع تقنية سيئة | ضمان عمر أداة ممتد |

نصيحة: بالنسبة للأدوات عالية الدقة مثل إدخالات الكربيد و مطاحن نهاية، من الأكثر أمانًا استخدام خدمة إعادة الطحن الاحترافية مثل إعادة.

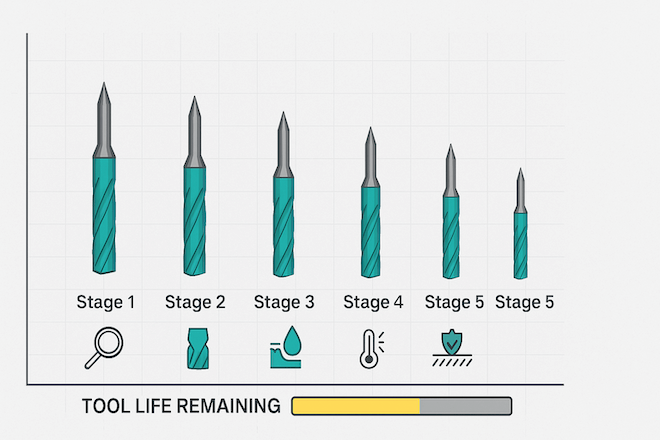

كم مرة يمكنك إعادة شحذ أداة الكربيد؟

هذا يعتمد على:

نوع الأداة

الحجم الأولي

طلب

جودة إعادة الطحن

عادةً، يمكن إعادة شحذ أدوات الكربيد من 3 إلى 5 مرات قبل الحاجة إلى استبدالها بالكامل.

قد تسمح أدوات الكربيد المُخصصة ذات الحواف السميكة بإعادة طحن أكثر. اطلع على دليلنا هنا:

👉 لماذا تتمتع أدوات القطع المصنوعة من كربيد التنغستن بمقاومة فائقة للتآكل

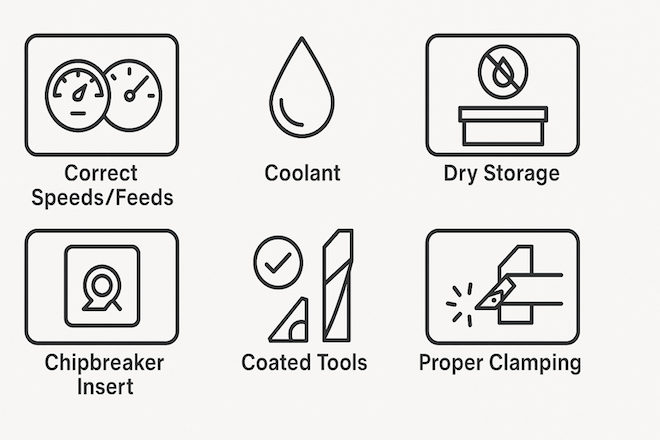

كيفية زيادة عمر الأداة بين عمليات الشحذ

استخدم هذه النصائح للحصول على عمر أطول للأداة وتأخير عملية الشحذ:

اختر الصحيح درجة الكربيد لموادك

استخدم سرعات القطع والتغذية المناسبة

تطبيق سائل التبريد أثناء التشغيل

تجنب الأحمال الصدمية أو القطع المتقطع

قم بتخزين الأدوات في صناديق جافة ومبطنة

استخدم أدوات كربيد مطلية للحصول على عمر أطول للارتداء

المزيد من النصائح هنا:

👉 نصائح الصيانة لإطالة عمر أدوات القطع المصنوعة من كربيد التنجستن

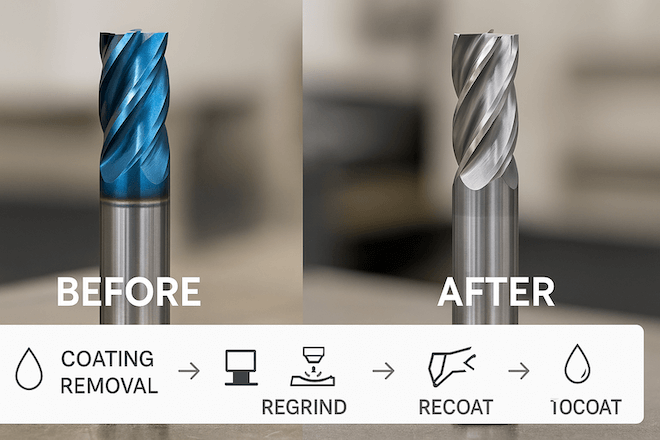

هل يمكن إعادة شحذ الأدوات المطلية؟

نعم، ولكن يجب إزالة الطلاء أولاً. تتم إزالة معظم الطلاءات باستخدام:

التجريد الكيميائي

النقش البلازمي

بعد الشحذ، يمكن إعادة طلاء الأداة لمزيد من الحماية.

خدمات إعادة التأهيل الموثوقة من Retop

في Retop، لا نقوم فقط بتوريد أدوات كربيد التنغستن عالية الأداء، بل نقدم أيضًا:

فحص وتقييم الأدوات

إعادة الشحذ والطحن الدقيق

خدمة إعادة طلاء الأدوات

إصلاح أو إعادة تشكيل الأدوات المخصصة

تضمن معدات الطحن CNC المتقدمة ومراقبة الجودة الصارمة أن أدواتك المعاد تجديدها تعمل وكأنها جديدة.

خاتمة

شحذ وتجديد أدوات كربيد التنغستن طريقة ذكية لإطالة عمرها وتوفير المال. باستخدام المعدات والتقنية المناسبة، أو باختيار مزود موثوق مثل ريتوب، يمكنك إعادة إحياء أدواتك القديمة والحفاظ على سير أعمالك بكفاءة.

إذا لم تكن متأكدًا من كيفية إعادة الطحن أو كنت بحاجة إلى مساعدة، تواصل معنا للحصول على الدعم. نحن هنا لمساعدتك في صيانة أدوات الكربيد الخاصة بك وتحسين أدائها.