Compressors are essential in many industries, but they are often subject to wear and tear, leading to costly downtime.

Tungsten carbide bushings improve compressor reliability by offering superior مقاومة التآكل, reducing maintenance, and extending service life.

In this article, we’ll explore how these bushings contribute to smoother, more efficient compressor performance.

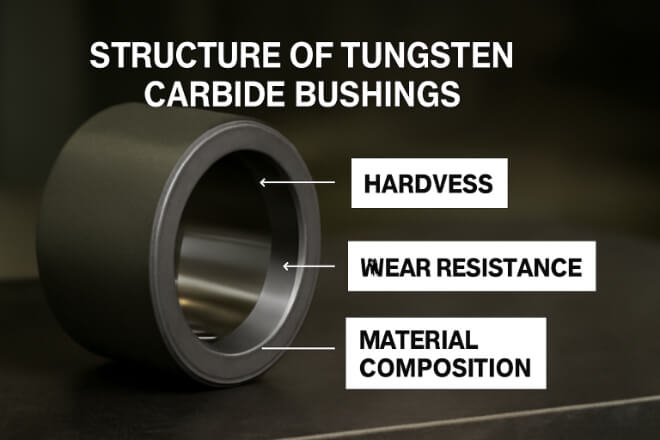

What Are Tungsten Carbide Bushings?

Tungsten carbide bushings are components made from a combination of tungsten and carbon, which together form a highly durable material.

These bushings are used as bearings to reduce friction between moving parts in compressors, which is essential to maintaining the smooth operation of the system.

Tungsten carbide’s exceptional صلابة و مقاومة التآكل make it an ideal choice for applications where components are subject to high stress, frequent motion, and abrasive materials.

The manufacturing process for tungsten carbide involves sintering tungsten powder at high temperatures, resulting in a material that is both dense and extremely hard.

This gives tungsten carbide bushings the ability to withstand harsh conditions that would degrade other materials.

How Tungsten Carbide Bushings Improve Compressor Reliability

In a compressor, the bushings are key components that support rotating shafts and reduce friction.

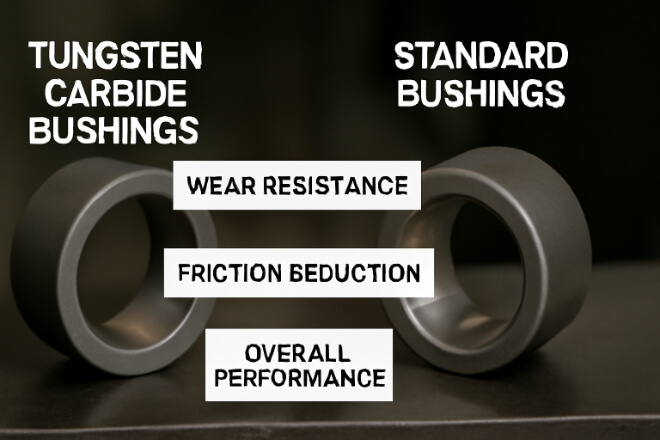

Tungsten carbide bushings offer several important benefits that directly contribute to improved reliability:

Compressors are exposed to significant friction, which can cause rapid wear and degradation of components.

Tungsten carbide bushings significantly reduce this wear, which helps the compressor continue to function effectively for longer periods without performance degradation.

Reduced Maintenance:

By reducing wear and preventing damage to the compressor’s moving parts, tungsten carbide bushings lower the frequency of repairs and maintenance.

This is especially important in industries where compressor downtime can result in costly interruptions.

عمر خدمة أطول:

The extreme صلابة of tungsten carbide means that bushings made from this material last longer than those made from standard materials like bronze or steel.

This results in fewer replacements, reducing overall operating costs and improving system reliability.

Corrosion and High-Temperature Resistance:

Many compressors operate in harsh environments, such as those in the oil and gas industry, where exposure to high temperatures, pressure, and corrosive substances is common.

Tungsten carbide bushings resist corrosion and maintain their strength even under high-temperature conditions, ensuring reliable performance.

Key Benefits of Tungsten Carbide Bushings for Compressors

Using tungsten carbide bushings in compressors provides several key benefits:

زيادة الموثوقية:

The main benefit is the enhanced reliability of the compressor.

Tungsten carbide bushings perform well under high pressure and temperature conditions, which means the compressor can operate at peak efficiency for longer periods.

توفير التكاليف:

While tungsten carbide bushings may come with a higher initial cost compared to other materials.

The long-term savings in maintenance and reduced downtime make them a cost-effective choice. Reduced failure rates lead to lower repair and replacement costs.

Improved Efficiency:

Tungsten carbide bushings help the compressor run more smoothly by reducing friction, which directly improves the overall efficiency of the system.

Lower friction means the compressor requires less energy to operate, which can lead to energy savings over time.

Protection Against Abrasive Materials:

في الصناعات مثل التعدين and oil extraction, compressors often deal with abrasive gases and materials.

Tungsten carbide bushings provide a high level of protection against the wear caused by these abrasive substances.

Applications of Tungsten Carbide Bushings in Compressors

Tungsten carbide bushings are widely used in various types of compressors across different industries:

Compressors in the oil and gas industry often deal with harsh conditions, including high pressures and abrasive materials.

Tungsten carbide bushings provide the durability and wear resistance needed to maintain reliability in these demanding environments.

In mining operations, compressors are used to power pneumatic tools and transport materials.

Tungsten carbide bushings help reduce wear from the abrasive materials commonly found in these environments.

المعالجة الكيميائية:

Compressors used in chemical plants must handle volatile substances, which can cause wear and corrosion.

Tungsten carbide bushings provide مقاومة التآكل and wear, ensuring long-term performance.

Manufacturing:

In industrial applications, compressors help power equipment and machinery.

Tungsten carbide bushings extend the service life of these compressors, reducing the risk of downtime and improving efficiency.

How Tungsten Carbide Bushings Contribute to Pump and Compressor Performance

Tungsten carbide bushings contribute to improved performance by enhancing the durability and reliability of compressors.

Here’s how they work to increase the effectiveness of the system:

تقليل الاحتكاك:

Tungsten carbide’s low friction properties ensure that the moving parts of a compressor operate smoothly, resulting in lower energy consumption and less wear on the components.

Smooth Operation:

The exceptional hardness of tungsten carbide ensures that the bushings remain intact and functional even under high stress.

This leads to smoother operation, which in turn reduces noise and vibration in the system.

Lower Operating Costs:

With reduced friction and wear, tungsten carbide bushings can help lower the overall operating costs of a compressor by improving its energy efficiency and reducing the frequency of repairs.

Challenges and Considerations When Using Tungsten Carbide Bushings

While بطانات كربيد التنغستن offer many benefits, there are a few considerations:

يكلف:

Tungsten carbide is a more expensive material compared to alternatives like bronze or steel.

However, the durability and longevity of tungsten carbide bushings mean that the higher initial cost is often justified by the long-term savings in maintenance and downtime.

هشاشة:

Tungsten carbide is extremely hard but also brittle. Improper installation or handling can lead to cracking or breakage.

It’s important to ensure proper installation and care during operation to avoid damage.

Material Compatibility:

In some cases, tungsten carbide may not be compatible with certain types of lubricants or other materials.

It’s important to consider the operating conditions and consult with experts to ensure the best match.

خاتمة

Tungsten carbide bushings are an excellent choice for improving compressor reliability.

With their wear resistance, high-temperature stability, and ability to withstand abrasive and corrosive environments, these bushings enhance the performance and longevity of compressors.

While they may come with a higher upfront cost, the long-term savings in maintenance, energy efficiency, and reduced downtime make them a valuable investment for industries relying on compressors for critical operations.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.