High RPM (Revolutions Per Minute) applications are common in many industries, from pumps and motors to turbines and compressors.

These systems often require components that can withstand extreme rotational speeds while maintaining performance and durability.

Tungsten carbide bushings are an ideal solution for such conditions, offering superior مقاومة التآكل, thermal stability, and high strength.

In this article, we will explore how tungsten carbide bushings perform in high RPM conditions, their advantages, and why they are the material of choice for high-speed machinery.

Why Tungsten Carbide Bushings Are Ideal for High RPM Conditions

High RPM applications place a lot of stress on components, requiring materials that can handle the friction, heat, and wear associated with rapid motion.

Tungsten carbide is an excellent choice for such conditions due to several key properties:

استثنائي صلابة: Tungsten carbide is one of the hardest materials available, making it highly resistant to wear and deformation at high speeds.

Low Friction: Tungsten carbide bushings offer low friction, reducing the risk of overheating and damage to components.

High Thermal Stability: Tungsten carbide maintains its strength and structure even at elevated temperatures, which is crucial in high RPM systems.

مقاومة التآكل: Tungsten carbide is resistant to corrosion, making it suitable for high-speed applications involving harsh chemicals or extreme environments.

These properties ensure that tungsten carbide bushings can handle the demands of high RPM machinery, providing long-lasting and reliable performance.

Key Benefits of Tungsten Carbide Bushings in High RPM Systems

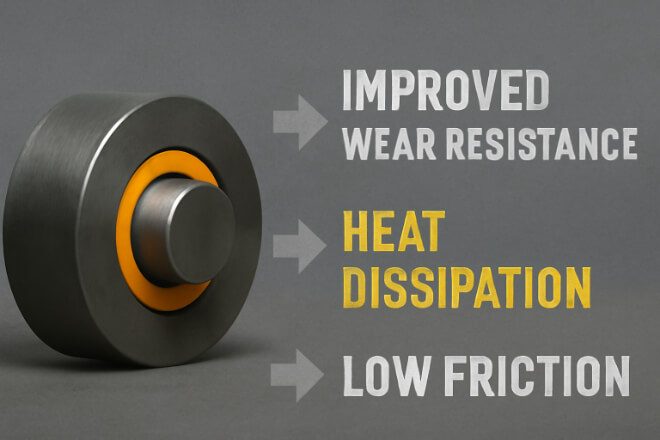

1). مقاومة التآكل

High RPM applications generate significant friction, which leads to wear and tear on components over time.

Tungsten carbide bushings, due to their hardness, resist wear much better than other materials.

This helps to extend the lifespan of the components, reducing the frequency of replacements and minimizing downtime.

- Example:

In pumps, the constant motion at high RPM can cause conventional materials to wear down quickly, resulting in leaks and reduced efficiency.

Tungsten carbide bushings can withstand these forces, maintaining performance for much longer.

2). Heat Dissipation

Friction at high speeds generates heat, which can lead to component failure if not properly managed.

Tungsten carbide has excellent thermal conductivity, allowing it to dissipate heat efficiently and prevent overheating.

- Example:

In turbine applications, high RPM leads to intense heat buildup. Tungsten carbide bushings help to maintain temperature stability, preventing thermal damage and improving overall system efficiency.

3). Low Friction

Tungsten carbide bushings have low coefficients of friction, reducing the amount of heat generated by frictional forces.

This is particularly important in high RPM applications where friction can quickly lead to wear and overheating.

- Example:

In high-speed motors, low friction is crucial to ensure smooth operation. Tungsten carbide bushings help to reduce friction, ensuring that the motor runs efficiently without excessive heat buildup.

4). Improved Reliability

The superior durability of tungsten carbide bushings leads to increased reliability in high RPM systems.

Since these bushings are less likely to wear out or deform, they help to prevent costly breakdowns and ensure that machinery operates smoothly over time.

- Example:

In compressors, the constant high-speed motion can put a lot of strain on components.

Tungsten carbide bushings improve reliability by providing robust support, reducing the likelihood of mechanical failures.

How Tungsten Carbide Bushings Perform in Specific High RPM Applications

1). High-Speed Motors

In high-speed motors, the continuous rotation creates significant friction and wear.

Tungsten carbide bushings provide excellent مقاومة التآكل and low friction, ensuring that the motor operates efficiently without overheating or excessive wear.

Performance: Tungsten carbide bushings handle high rotational speeds without degradation, maintaining performance and extending motor lifespan.

2). Pumps and Compressors

Pumps and compressors often operate at high RPM to move fluids or gases.

Tungsten carbide bushings are ideal for these applications, as they resist wear, prevent overheating, and maintain smooth operation under high-speed conditions.

Performance: Tungsten carbide bushings in pumps and compressors help maintain consistent performance, preventing leaks and ensuring continuous operation.

3). Turbines

Turbines operate at extremely high speeds, generating significant friction and heat.

Tungsten carbide bushings are used in turbine applications to withstand these conditions, providing reliable performance and preventing mechanical failure due to excessive wear.

Performance: Tungsten carbide bushings provide excellent heat dissipation and مقاومة التآكل, allowing turbines to run efficiently at high speeds.

4). Centrifugal Machinery

Centrifugal machinery, such as centrifuges and separators, operates at high RPM to separate materials based on their density.

Tungsten carbide bushings are used in these systems to ensure smooth operation, reduce friction, and extend the lifespan of the machinery.

- Performance: Tungsten carbide bushings allow centrifugal machinery to operate without friction-related issues, improving efficiency and reliability.

How to Choose the Right Tungsten Carbide Material for High RPM Applications

When selecting tungsten carbide bushings for high RPM systems, several factors should be considered:

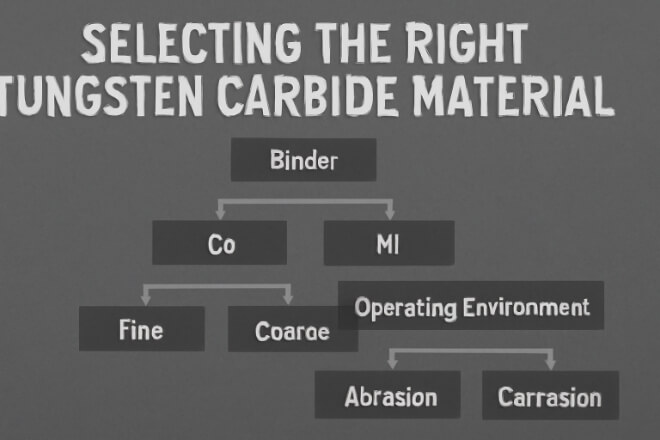

1). Binder Material

The binder material in tungsten carbide, such as cobalt or nickel, affects the bushing’s properties.

For high RPM applications, a bushing with a cobalt binder is typically preferred due to its صلابة and ability to withstand high-impact and high-stress conditions.

2). Grain Size

The grain size of tungsten carbide affects its hardness and wear resistance.

For high-speed applications, fine-grain tungsten carbide is often preferred because it offers superior wear resistance and a smoother surface finish.

3) بيئة التشغيل

Consider the environment in which the high RPM system will operate.

If the system is exposed to chemicals, corrosive liquids, or extreme temperatures, tungsten carbide with a nickel binder may be the best choice due to its corrosion resistance.

4). Temperature and Pressure Conditions

High RPM systems often experience significant temperature and pressure fluctuations.

It is essential to choose a tungsten carbide material that can maintain its strength and durability under these conditions.

Nanostructured tungsten carbide, with its superior toughness, is ideal for high-performance, high-speed applications.

Manufacturing Process for Tungsten Carbide Bushings

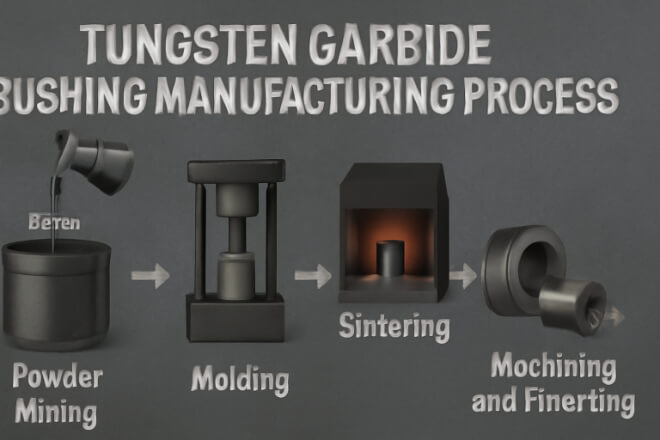

Tungsten carbide bushings are manufactured through several key steps to ensure they meet the specific demands of high RPM applications:

Powder Mixing: مسحوق كربيد التنغستن is mixed with a binder material (such as cobalt or nickel).

Molding: The mixture is pressed into molds to create the desired bushing shape.

Sintering: The molded bushings are heated at high temperatures to bond the particles and form a dense material.

Machining and Finishing: The sintered bushings are machined to achieve the desired dimensions and surface finish.

This manufacturing process ensures that tungsten carbide bushings are durable and can withstand the extreme conditions of high RPM systems.

خاتمة

Tungsten carbide bushings provide exceptional performance in high RPM conditions, offering wear resistance, heat dissipation, and reliability.

Their ability to withstand high friction, extreme temperatures, and corrosive environments makes them the material of choice for high-speed machinery.

By selecting the right tungsten carbide material, industries can improve the efficiency, lifespan, and reliability of their high RPM systems.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.