In woodworking, achieving precision and efficiency is critical for creating high-quality finished products.

Woodworking machines, from saws to routers and planers, require tools that can withstand wear, maintain sharpness, and deliver consistent results.

Tungsten carbide tips have become the preferred choice in woodworking applications due to their صلابة, durability, and precision.

This blog will explore how tungsten carbide tips perform in woodworking machines and why they are an excellent investment for manufacturers looking to improve productivity and reduce tool replacement costs.

Why Tungsten Carbide Tips Are Ideal for Woodworking Machines

Tungsten carbide tips are highly valued in the woodworking industry for their outstanding performance and ability to withstand the harsh demands of cutting, shaping, and finishing wood.

Here are the key reasons why they are so effective.

1). Exceptional صلابة and Sharpness

Tungsten carbide is one of the hardest materials available, making it ideal for cutting through wood, especially dense or hardwoods.

The hardness ensures that carbide tips retain their sharp cutting edges for a longer time than standard steel tools, reducing the frequency of tool changes and ensuring clean, precise cuts.

2). مقاومة التآكل

Woodworking involves continuous cutting, which results in significant friction between the tool and the material.

Tungsten carbide tips resist wear much better than other materials, ensuring that the tools maintain cutting performance over extended periods.

This resistance to wear translates to fewer tool replacements, which helps reduce operational costs in woodworking shops.

3). Heat Resistance

Woodworking machines often generate heat due to friction during the cutting process.

Tungsten carbide’s excellent heat resistance helps to maintain the sharpness of the tool and prevent deformation, even in high-speed operations.

This heat resistance ensures that carbide tips continue to perform effectively and retain their shape for longer periods.

Performance Benefits of Tungsten Carbide Tips in Woodworking Machines

Using tungsten carbide tips in woodworking machines offers significant performance benefits that improve the efficiency and quality of wood processing operations.

1). Increased Cutting Precision

Tungsten carbide tips allow woodworking machines to achieve high precision when cutting, shaping, or finishing wood.

Whether it’s a circular saw, router, or planer, carbide tips help create smooth, clean cuts with minimal effort.

This precision ensures that woodworking products meet the required specifications and quality standards.

2). Longer Tool Life

One of the biggest advantages of tungsten carbide tips is their longevity.

These tips last much longer than steel or other materials, reducing the need for frequent tool replacements.

In woodworking, where machines operate for long hours, carbide tips ensure longer periods of continuous operation without compromising cutting performance.

3). Reduced Downtime and Maintenance

Since tungsten carbide tips last longer and require less frequent replacement, woodworking operations experience reduced downtime.

Machines can run longer without interruptions for tool changes or maintenance.

This increased uptime improves productivity and lowers operational costs by reducing maintenance efforts and tool replacement expenses.

Applications of Tungsten Carbide Tips in Woodworking Machines

Tungsten carbide tips are used in a wide variety of woodworking machines, each requiring high performance for specific tasks. These tools are crucial for many types of wood processing.

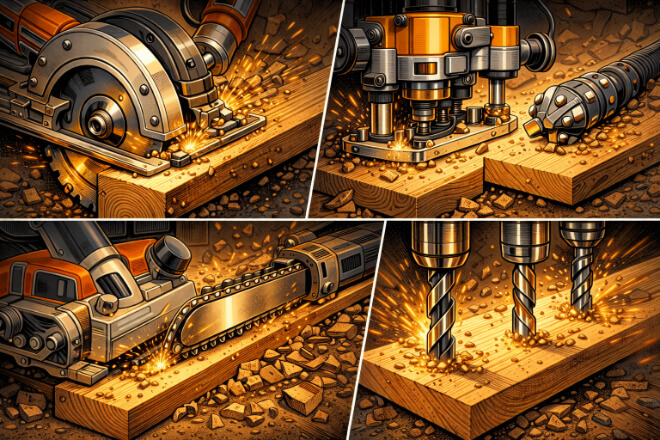

1). Saw Blades

Circular saw blades, band saw blades, and table saw blades often use tungsten carbide tips to cut through hardwoods and other dense materials.

The tips’ durability ensures that these saw blades can handle tough cuts without losing their sharpness, making them ideal for both rough cutting and fine finishing.

2). Router Bits

Router bits with tungsten carbide tips are used to shape and edge wood, and they must be durable enough to withstand continuous use.

The hardness and sharpness of carbide tips allow router bits to create clean, detailed cuts, whether for decorative edges, grooves, or hollowing operations.

3). Planer and Jointer Blades

Planers and jointers use tungsten carbide tips to smooth and flatten wood surfaces.

These tools need to cut through tough and often uneven material, and carbide tips ensure that the blades remain sharp and effective, allowing for a smooth finish.

4). Drill Bits

Tungsten carbide drill bits are often used in woodworking for drilling holes in wood.

These tips provide the strength and durability needed to drill through tough wood fibers without dulling quickly, making them an excellent choice for high-volume drilling operations.

Maximizing the Performance of Tungsten Carbide Tips in Woodworking Machines

To get the most out of tungsten carbide tips, it’s essential to use them properly and maintain them well. Here are some tips to optimize their performance in woodworking operations:

1). Adjusting Cutting Parameters

Cutting speed, feed rate, and depth of cut should be adjusted to optimize the performance of tungsten carbide tips in woodworking machines.

Operating within the correct parameters ensures that the tips stay sharp for longer and perform efficiently, preventing excessive wear and ensuring consistent cutting.

2). Regular Inspections and Maintenance

Regular inspections and maintenance are key to keeping tungsten carbide-tipped tools in top condition.

Checking for wear, cracks, or other signs of damage allows for early detection of issues, which can be addressed before the tool fails.

Proper maintenance also involves sharpening carbide tips when necessary to keep cutting performance optimal.

3). Proper Storage and Handling

Proper storage and handling of tungsten carbide tools help to prevent damage.

Storing tools in a dry, clean environment and using them according to the manufacturer’s recommendations will help maintain their durability and extend their useful life.

The Cost-Effectiveness of Tungsten Carbide Tips in Woodworking

While tungsten carbide tips may have a higher initial cost than other materials, their long-term benefits make them a cost-effective choice for woodworking operations.

1). Fewer Tool Replacements

Tungsten carbide tips last longer than traditional materials, meaning they need to be replaced less often.

This reduces the overall cost of purchasing and storing replacement tools, contributing to significant savings over time.

2). Lower Operational Costs

With fewer tool replacements and less maintenance required, the overall operational costs are lower.

Additionally, the extended tool life and increased productivity from using tungsten carbide tips reduce downtime and labor costs, further improving the cost-effectiveness of woodworking operations.

3). Increased Productivity

The durability and performance of tungsten carbide tips help increase productivity by reducing downtime for tool changes, maintaining cutting efficiency, and improving the speed of operations.

More efficient cutting leads to faster job completion and improved output, helping businesses meet deadlines and increase profits.

خاتمة

Tungsten carbide tips play a crucial role in enhancing the performance and efficiency of woodworking machines.

Their exceptional hardness, wear resistance, and heat tolerance make them the ideal choice for cutting, shaping, and finishing wood.

By using tungsten carbide tips, woodworking businesses can achieve high precision, reduced downtime, longer tool life, and lower operational costs, making them a smart investment for the long term.

Whether for cutting, routing, or planing, tungsten carbide tips provide the durability and performance needed to succeed in a competitive market.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.