In the world of manufacturing and machining, tool life is a critical factor that impacts productivity, cost, and overall efficiency.

Tungsten carbide tips are known for their durability and precision, making them a popular choice in various industries.

However, to get the most out of tungsten carbide tools, it’s essential to implement the right techniques that maximize their lifespan.

In this blog, we’ll explore key strategies and best practices for improving tool life with tungsten carbide tips, ensuring that your tools perform at their best for longer.

Understanding Tungsten Carbide Tips and Their Durability

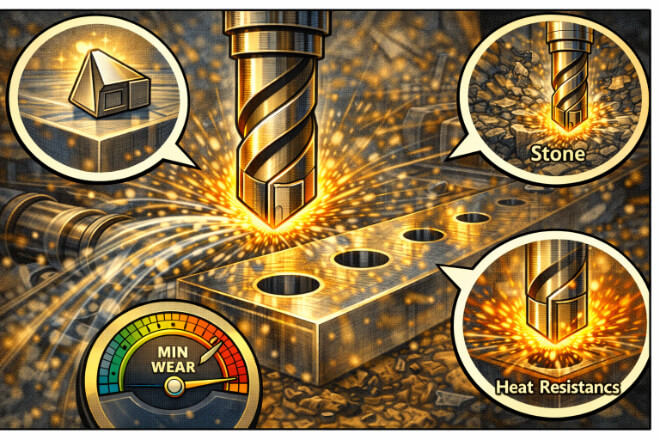

Tungsten carbide is one of the hardest materials used in cutting tools. The exceptional صلابة و مقاومة التآكل make tungsten carbide tips ideal for high-performance machining applications.

These tips can withstand extreme pressure, high temperatures, and abrasive conditions, making them a preferred choice for industries that require precision and durability.

1). Why Tungsten Carbide Tips Are Durable

Tungsten carbide’s hardness, صلابة, and wear resistance are the main factors that contribute to its long-lasting performance.

The material’s ability to resist abrasion, heat, and deformation helps maintain sharp cutting edges, which directly influences tool longevity.

By using tungsten carbide tips, manufacturers can reduce the frequency of tool replacements, resulting in significant cost savings over time.

Techniques to Extend the Life of Tungsten Carbide Tips

While tungsten carbide tips are inherently durable, certain practices can further extend their lifespan.

These techniques focus on optimizing the conditions under which the tools operate, ensuring that they remain effective over time.

1). Optimizing Cutting Parameters

One of the most important factors in extending the life of tungsten carbide tips is adjusting the cutting parameters—cutting speed, feed rate, and depth of cut.

Properly calibrated settings can prevent excessive wear on the tool and reduce the chances of tool failure.

سرعة القطع: Running carbide tips at the right cutting speed is crucial for preventing heat buildup. Too high a speed can cause overheating and tool degradation, while too low a speed can cause excessive friction, resulting in premature wear.

Feed Rate: The feed rate should be optimized to ensure that the cutting tool is not overloaded. Too fast a feed rate increases cutting forces and wear, while too slow a feed rate can reduce machining efficiency.

Depth of Cut: Shallow cuts reduce the stress on carbide tips, whereas deeper cuts require more power and increase wear. Adjusting the depth of cut based on the material being worked on helps prolong tool life.

2). Proper Cooling and Lubrication

Coolant and lubrication are essential for controlling heat during machining operations.

Excessive heat can cause carbide tips to soften, reducing their effectiveness. Proper cooling can extend tool life by preventing overheating and reducing friction.

Water-Based Coolants: These coolants are effective for cooling and flushing away debris during cutting operations, maintaining tool performance and preventing heat buildup.

Oil-Based Lubricants: These lubricants reduce friction and help prevent tool wear, particularly when working with tougher materials.

Using the right coolant and lubrication, in the correct amounts, ensures that carbide tips perform at their best for longer periods.

Proper Tool Maintenance for Tungsten Carbide Tips

Regular maintenance is key to keeping carbide tools in optimal condition.

By inspecting tools regularly, maintaining them properly, and performing reconditioning when needed, businesses can extend tool life and reduce overall costs.

1). Routine Inspections

Checking for signs of wear, cracks, or chips on tungsten carbide tips should be part of a regular maintenance routine.

Early detection of damage can prevent the need for complete tool replacement and allow for reconditioning.

2). Reconditioning and Sharpening

Tungsten carbide tips can be reconditioned or resharpened to restore their cutting effectiveness.

Resharpening extends the tool’s lifespan and ensures that it continues to provide precise cuts. Reconditioning is a cost-effective solution compared to purchasing new tools.

3). Tool Storage

Proper storage of tungsten carbide tips also plays an important role in their longevity.

Store the tools in a clean, dry environment to prevent rust and corrosion. Avoid dropping or mishandling the tools to prevent physical damage.

Choosing the Right Grade of Tungsten Carbide Tips

Different grades of tungsten carbide are designed for specific applications.

The right grade should be selected based on the material being cut and the type of operation being performed.

Choosing the correct grade will ensure that the tool can withstand the specific stresses it will encounter, helping to extend its service life.

1). Material Compatibility

Harder grades of tungsten carbide are ideal for cutting tougher materials such as steel, titanium, and other hard metals.

For softer materials, a standard grade of carbide might suffice. Using the correct grade based on the material being processed can help prevent excessive wear and tear on the tool.

2). Grade vs. Cost

Higher-grade tungsten carbide tools typically come at a higher price, but they offer superior مقاومة التآكل and longer life, making them more cost-effective in the long run.

It’s important to balance initial cost with the tool’s expected lifespan and performance.

The Impact of Material Being Cut on Tool Life

The material being cut plays a significant role in how long tungsten carbide tips will last.

Softer materials will cause less wear on the tools, while tougher, more abrasive materials will wear down carbide tips more quickly.

1). Cutting Hard Materials

When cutting hard materials like steel, titanium, or composites, carbide tips are exposed to higher stresses, which can lead to faster wear.

In such cases, selecting higher-grade carbide tips and optimizing cutting parameters (like feed rate and cutting speed) can help reduce wear and extend tool life.

2). Cutting Soft Materials

When cutting softer materials like wood or plastic, tungsten carbide tips last longer because the material is less abrasive.

In these cases, using a lower-grade carbide tip may be sufficient, reducing upfront costs while still offering excellent performance.

خاتمة

Extending the life of tungsten carbide tips requires a combination of proper cutting techniques, routine maintenance, and the right material selection.

By optimizing cutting parameters, ensuring proper cooling and lubrication, and performing regular tool inspections and reconditioning, businesses can maximize the performance and lifespan of their carbide tools.

Investing in these best practices will lead to significant cost savings and enhanced efficiency in the long term.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.