Tungsten carbide bushings are known for their durability and مقاومة التآكل.

However, in boundary lubrication conditions, where the lubricant film is too thin to fully separate the bushing from the mating surface, ensuring proper lubrication is essential to prevent friction and wear.

This article will discuss the role of lubrication in boundary conditions, the factors that affect its performance, and best practices for maintaining tungsten carbide bushings in these environments.

What is Boundary Lubrication?

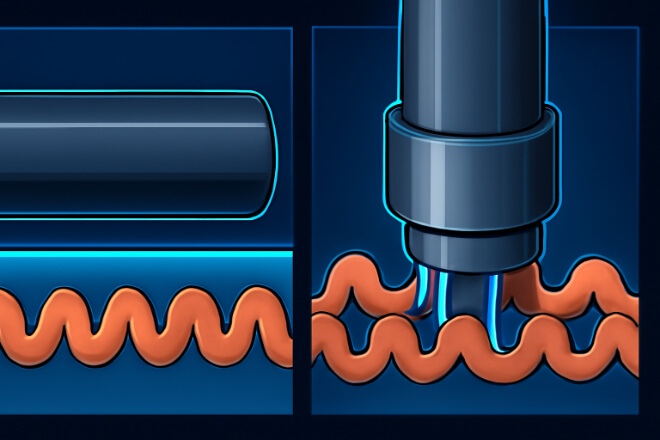

Boundary lubrication occurs when the lubricant film between two surfaces is too thin to fully separate them.

Under these conditions, the surfaces experience some degree of direct contact, resulting in increased friction and wear.

This situation is common in systems that operate at high pressures, speeds, or in environments where the lubricant is not sufficient to form a complete fluid film.

Characteristics of Boundary Lubrication:

Thin Lubricant Film: The lubricant is present but insufficient to create a full film separating the bushing and mating surface.

Increased Contact: Surfaces experience intermittent direct contact, increasing friction and wear.

Higher Temperature: Due to friction, temperatures rise, further reducing the efficiency of the lubrication.

In such conditions, ensuring the right type of lubricant and implementing proper lubrication strategies is crucial for preventing surface damage and excessive wear.

The Role of Lubrication in Tungsten Carbide Bushings

Tungsten carbide bushings, known for their صلابة و مقاومة التآكل, still require lubrication, especially in boundary conditions.

While tungsten carbide is a robust material, prolonged operation under boundary lubrication can lead to surface damage, such as galling, scoring, or wear, if not properly managed.

Why Lubrication Matters for Tungsten Carbide Bushings:

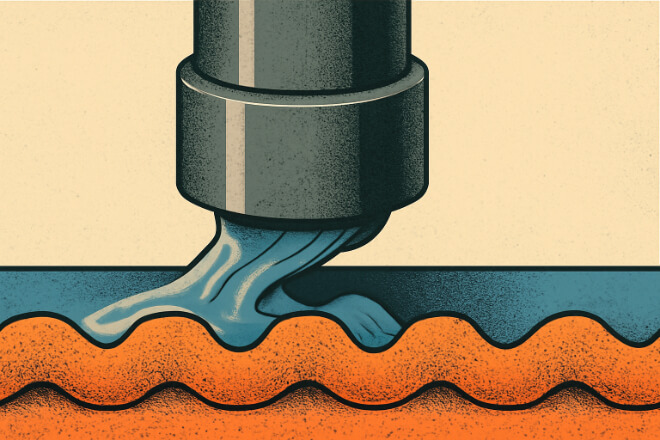

Minimizes Friction: Proper lubrication reduces friction between the bushing and mating surfaces, preventing excessive wear.

Reduces Surface Damage: Lubricants act as a barrier, preventing direct metal-to-metal contact and reducing the risk of scratches, scoring, and other forms of damage.

Prevents Overheating: Lubrication helps to dissipate heat generated by friction, preventing the bushing from overheating and maintaining its performance.

Enhances Durability: Consistent lubrication extends the lifespan of tungsten carbide bushings by reducing the rate of wear.

Factors Affecting Lubrication in Boundary Conditions

When operating under boundary lubrication conditions, several factors can affect the performance of the lubricant and, consequently, the bushing.

These factors must be carefully considered when designing a lubrication plan.

Key Factors to Consider:

Lubricant Viscosity:

The viscosity of the lubricant determines how effectively it can form a film between the bushing and the mating surface. A higher viscosity lubricant may be more effective in boundary conditions.

Load and Pressure:

The pressure and load on the bushing affect how much the lubricant film is compressed. Higher loads may reduce the effectiveness of the lubricant and increase wear.

Temperature:

Temperature fluctuations can affect the viscosity of the lubricant. High temperatures can reduce the lubricant’s effectiveness, while low temperatures can cause it to become too thick.

Speed of Operation:

The speed at which the bushing operates affects the formation of the lubricant film.

Higher speeds generally promote full-film lubrication, but in boundary conditions, the speed may not be enough to maintain that film.

Lubricant Type:

Different types of lubricants (e.g., oils, greases, solid lubricants) offer varying levels of protection and performance in boundary lubrication. Choosing the right lubricant is essential for minimizing wear and damage.

Choosing the Right Lubricant for Tungsten Carbide Bushings

Selecting the right lubricant is critical for optimizing the performance of tungsten carbide bushings in boundary lubrication conditions.

The lubricant should be able to withstand high pressures, provide adequate lubrication, and reduce friction while operating under extreme conditions.

1). Types of Lubricants:

Oils:

Oils provide a thin film of lubrication and are commonly used in high-speed applications.

They are often preferred in boundary lubrication because they can reduce friction while allowing for a higher viscosity.

Greases:

Greases are thicker than oils and can stay in place longer. They are used in applications where oils may not stay in place or provide adequate protection under pressure.

Solid Lubricants:

In extreme cases, solid lubricants such as graphite or molybdenum disulfide may be used.

These lubricants can withstand very high pressures and temperatures but are generally less effective in reducing friction than oils or greases.

2). Lubricant Selection Criteria:

Viscosity: Choose a lubricant with the appropriate viscosity for the operating conditions. It should be thick enough to provide a protective film but not so thick that it causes excess friction.

Additives: Look for lubricants with anti-wear additives, extreme pressure additives, or anti-oxidants to help protect against wear, corrosion, and oxidation, especially in boundary lubrication.

Compatibility: Ensure that the lubricant is compatible with the materials in the system, particularly the tungsten carbide bushing and the shaft or housing.

Best Practices for Lubrication in Boundary Conditions

Proper lubrication is essential to ensure the performance and longevity of tungsten carbide bushings in boundary lubrication conditions. Here are some best practices to follow:

Best Practices for Lubrication:

Frequent Lubrication Checks: In boundary lubrication conditions, lubricants can break down more quickly. Regular checks and replenishment of the lubricant are essential to maintain protection.

Apply Lubricant at Optimal Points: Ensure that the lubricant is applied at the right points in the system, particularly at contact areas where friction is highest. This will help prevent direct contact between the bushing and mating surface.

Maintain Proper Operating Temperatures: Use cooling systems or temperature control methods to ensure that the operating temperature stays within the optimal range for the lubricant to work effectively.

Monitor Load and Pressure: Keep an eye on the load and pressure on the bushing, as these factors can affect the lubricant’s ability to protect the surfaces. Adjust the lubrication plan as needed to account for changes in the operating environment.

Use Lubricant with Anti-Wear Additives: Choose lubricants that contain additives to reduce wear and protect the bushing and shaft from damage.

خاتمة

Proper lubrication is crucial for ensuring the longevity and performance of tungsten carbide bushings in boundary lubrication conditions.

By selecting the right lubricant, monitoring key factors like temperature and pressure, and following best practices for lubrication, you can minimize friction, prevent wear, and extend the life of your bushings.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.