مقدمة

تُعدّ المسامية مفهومًا بالغ الأهمية في علم المواد، خاصةً فيما يتعلق بالمواد عالية الأداء مثل كربيد التنغستن (WC) المستخدم في الأدوات الصناعية. ورغم إغفالها في كثير من الأحيان، إلا أن المسامية تلعب دورًا هامًا في تحديد القوة الميكانيكية ومقاومة التآكل والموثوقية العامة لأدوات الكربيد. تُوضح هذه المقالة ماهية المسامية، وكيفية تشكلها، وأهميتها، وكيفية تعامل المصنّعين معها.

ما هي المسامية؟

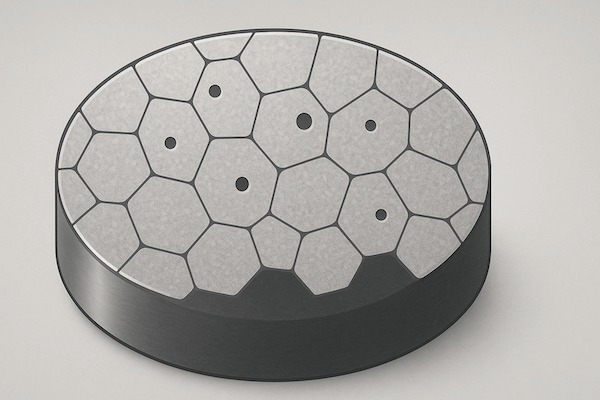

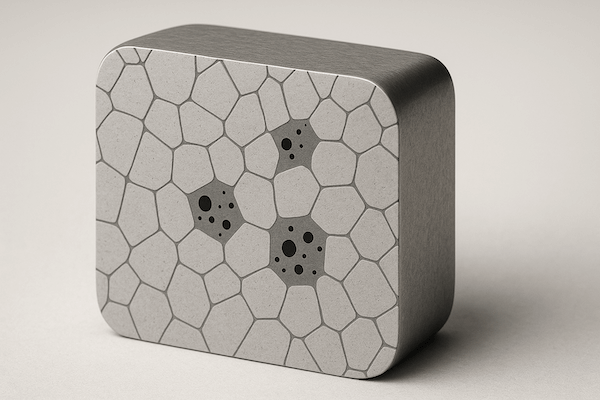

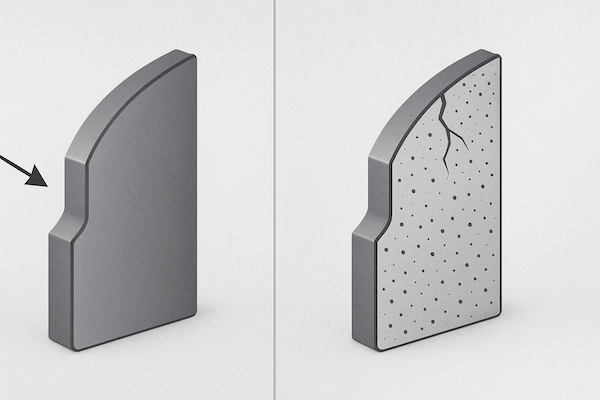

تشير المسامية إلى وجود فراغات أو مسام صغيرة داخل المادة. قد تكون هذه الفراغات مجهرية أو مرئية بالعين المجردة، وتنتج عن عدم اكتمال التكثيف أثناء عملية التصنيع. في الكربيدات الأسمنتية، المسامية هي الفراغ الذي يبقى شاغرًا بين حبيبات كربيد التنغستن والمعادن الرابطة، وعادةً ما تكون من الكوبالت أو النيكل.

كيف تتشكل المسامية في أدوات الكربيد

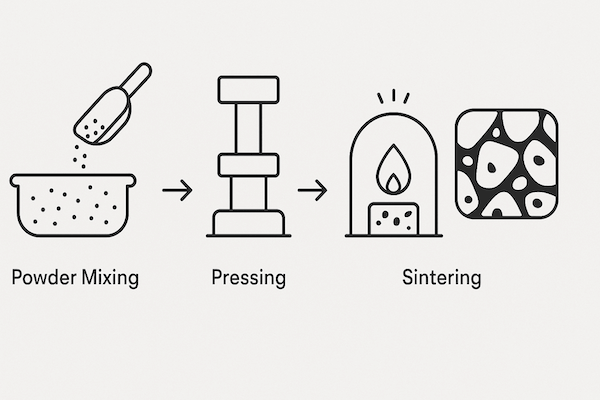

أدوات كربيد التنغستن يتم تصنيعها عادةً باستخدام تقنيات مسحوق المعادن التي تشمل خلط المسحوق والضغط والتلبيد. أثناء التلبيدتؤدي درجات الحرارة المرتفعة إلى ذوبان المادة الرابطة المعدنية وترابط حبيبات WC. ومع ذلك، إذا كانت ظروف التلبيد غير مثالية أو كانت جودة المواد الخام رديئة، فقد تبقى جيوب هوائية صغيرة، مما يُشكل المسامية.

تشمل الأسباب الشائعة للمسامية ما يلي:

ترطيب الرابط غير الكامل

توزيع المسحوق غير موحد

درجة حرارة التلبيد أو الوقت غير الكافي

الشوائب في المواد الخام

أنواع المسامية في كربيد التنغستن

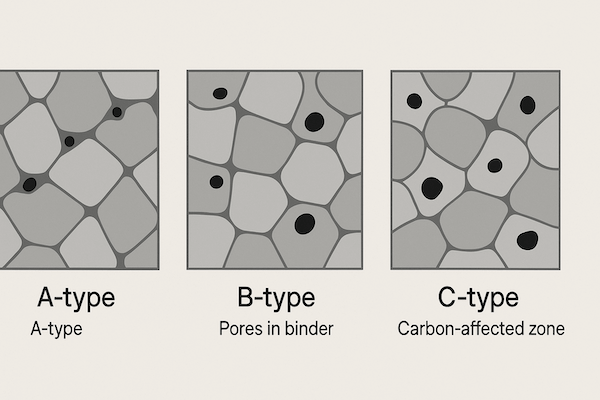

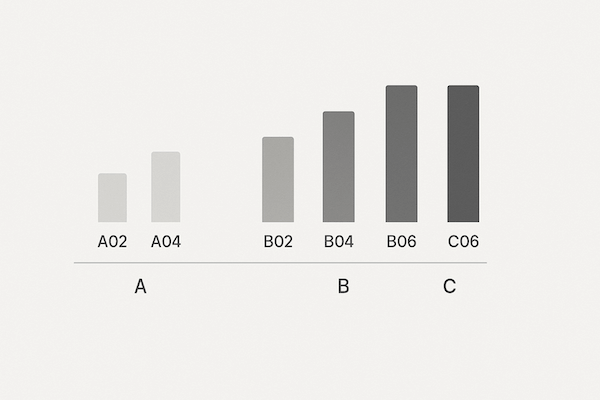

يتم تصنيف المسامية في كربيد الأسمنت عادة إلى ثلاثة أنواع:

النوع أ (المسام في طور الكربيد): يحدث بسبب التكثيف غير الكامل لحبيبات WC.

النوع ب (المسام في مرحلة الرابطة): غالبًا بسبب احتباس الغاز أو ضعف البلل.

النوع C (المسامية المرتبطة بالكربون): تنتج عن اختلال توازن الكربون، مثل تكوين الكربون الحر أو مرحلة إيتا.

يمكن لكل نوع أن يؤثر على أداء الأداة بشكل مختلف ويتم تصنيفه عادةً باستخدام المعايير الدولية مثل ISO 4505.

لماذا المسامية مهمة

للمسامية تأثير مباشر على الخواص الميكانيكية لأدوات كربيد التنغستن. قد تؤدي مستويات المسامية العالية إلى:

مخفض صلابة والقوة

الكسر أو التشقق المبكر

انخفاض الحرارة و مقاومة التآكل

عمر الأداة غير المتوقع

حتى الاختلافات الصغيرة في المسامية يمكن أن تؤثر بشكل كبير على كيفية أداء الأداة تحت الضغط - خاصة في التطبيقات الصعبة مثل القطع أو التعدين أو التشغيل عالي السرعة.

كيف يتحكم المصنعون في المسامية

يعد التحكم في المسامية أمرًا أساسيًا لإنتاج أدوات كربيد موثوقة. مصنعي أدوات الكربيد المتقدمة اعتماد عدة تقنيات منها:

التلبيد بالفراغ أو الضغط لتحسين التكثيف

الضغط الساخن المتساوي القياس (HIP) لإزالة المسام الداخلية

تحسين حبيبات المسحوق وخلطه

مراقبة الجودة الصارمة ومعايير تصنيف المسامية

الهدف هو تحقيق بنية مجهرية موحدة وكثيفة تعمل على تعزيز متانة الأداة وتناسقها.

خاتمة

قد تكون المسامية غير مرئية، لكن آثارها ليست كذلك. بالنسبة لأدوات كربيد التنغستن، يُعد فهم المسامية والتحكم بها أمرًا بالغ الأهمية لضمان الأداء العالي والسلامة وطول العمر. سواء كنت صانع أدوات أو مهندسًا أو مستخدمًا نهائيًا، فإن إدراك هذا العامل الخفي يُمكن أن يُؤدي إلى اختيار مواد أفضل وزيادة موثوقية المنتج.