In industries that rely on high-performance equipment, maximizing tool efficiency is critical to reducing operational costs.

Tungsten carbide tips, known for their durability and مقاومة التآكل, offer significant advantages in such environments.

While the initial cost of tungsten carbide tips may be higher compared to traditional materials, they can lead to considerable savings in the long run by reducing downtime, maintenance costs, and tool replacements.

This blog will explore how investing in tungsten carbide tips can help businesses save money, improve equipment performance, and boost overall profitability.

Why Tungsten Carbide Tips Are Ideal for High-Performance Equipment

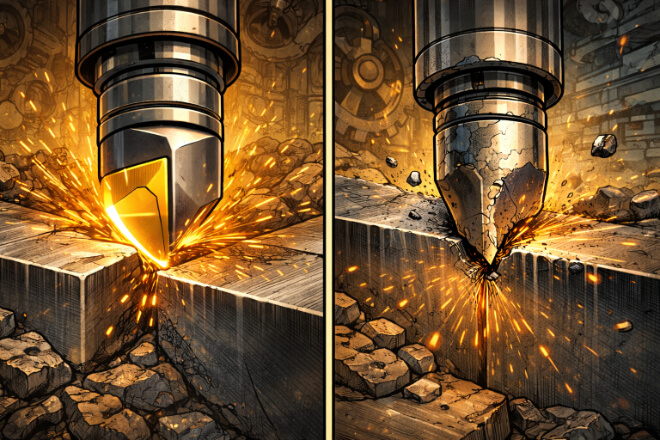

Tungsten carbide is one of the hardest materials available, making it an ideal choice for high-performance tools that are subject to extreme wear.

High-performance equipment, such as drills, saws, and cutters, often works in harsh conditions where standard tools would quickly degrade.

Tungsten carbide tips can withstand these demanding environments, offering enhanced performance and longevity.

Key Benefits of Tungsten Carbide Tips:

مقاومة التآكل: Tungsten carbide tips are highly resistant to wear, making them perfect for tools that cut, grind, or drill hard materials.

متانة: The toughness of tungsten carbide allows tools to last longer, even under intense pressure and extreme temperatures.

مقاومة الحرارة: Tungsten carbide maintains its صلابة at higher temperatures, making it suitable for high-speed operations where heat is generated.

By using tungsten carbide tips in high-performance equipment, businesses can reduce the frequency of tool replacements, cut down on maintenance, and improve overall efficiency.

Reducing Tool Replacement Costs

One of the most significant cost-saving benefits of using tungsten carbide tips in high-performance equipment is the reduction in tool replacement frequency.

Tungsten carbide tools last much longer than those made from softer materials, such as high-speed steel (HSS) or ceramics.

This means businesses spend less on purchasing replacement tips and can allocate resources to other areas of production.

How Tungsten Carbide Reduces Tool Replacement Costs:

Longer Lifespan: Tungsten carbide tips can handle more wear before they need to be replaced, reducing the frequency of replacements and associated costs.

زيادة الإنتاجية: With fewer tool replacements, downtime is reduced, leading to higher overall productivity. Fewer replacements also mean less labor is needed for tool changes.

Lower Material Costs: Tungsten carbide’s durability means fewer wasted resources in replacing damaged tools, helping companies maximize their material investment.

In industries where tools are used continuously, the cost savings from reduced tool replacement can add up significantly.

Lower Maintenance and Repair Costs

In addition to reducing replacement costs, tungsten carbide tips can lower maintenance and repair expenses.

Tools made from softer materials tend to wear out faster, requiring frequent sharpening, repairs, and adjustments.

Tungsten carbide tips, on the other hand, maintain their sharpness and effectiveness for much longer, requiring less frequent maintenance.

How Tungsten Carbide Helps Lower Maintenance Costs:

Fewer Sharpening Needs: Tungsten carbide tools stay sharper for longer, reducing the need for regular sharpening and the associated costs.

Reduced Breakdowns: Since tungsten carbide tools are less prone to damage, the likelihood of unexpected tool failures and breakdowns is lower.

وقت تعطل أقل: With fewer repairs and less maintenance required, operations can run smoothly without interruption, reducing the downtime that can be costly for businesses.

By using tungsten carbide tips, businesses can extend the intervals between tool servicing and reduce the costs associated with keeping equipment in good working order.

Improved Equipment Performance and Efficiency

The superior performance of tungsten carbide tips can lead to more efficient operations, which translates to cost savings.

Equipment that runs more efficiently requires less energy, has fewer breakdowns, and operates faster, all of which contribute to reduced operational costs.

How Tungsten Carbide Improves Equipment Performance:

Faster Processing: Tungsten carbide tips maintain their cutting efficiency even during high-speed operations, enabling faster processing times.

Higher Precision: The durability of tungsten carbide ensures that tools maintain their sharpness and precision over a longer period, leading to higher-quality outputs and fewer defects.

Better Heat Dissipation: Tungsten carbide’s resistance to heat allows equipment to operate at higher speeds without suffering from overheating, improving both efficiency and longevity.

With improved performance, equipment requires less energy and time to complete tasks, leading to significant cost savings.

Total Cost of Ownership (TCO) and ROI

When evaluating the cost savings of tungsten carbide tips, it’s important to consider the Total Cost of Ownership (TCO), which includes the upfront purchase price, maintenance costs, and operational costs over the lifespan of the tools.

Although tungsten carbide tips typically have a higher initial cost than alternative materials, their long-term benefits far outweigh the initial investment, providing a higher return on investment (ROI).

TCO Breakdown for Tungsten Carbide Tips:

| Cost Factor | أطراف كربيد التنغستن | Alternative Materials (e.g., HSS) |

|---|---|---|

| Initial Purchase Price | أعلى | أدنى |

| تكاليف الصيانة | أدنى | أعلى |

| Replacement Frequency | Less Frequent | More Frequent |

| Tool Lifespan | Longer | أقصر |

| Downtime | الحد الأدنى | أعلى |

As shown in the table, while the initial cost of tungsten carbide tips is higher, their longer lifespan, lower maintenance costs, and reduced downtime result in a lower TCO, making them a more cost-effective solution in the long run.

خاتمة

Using tungsten carbide tips in high-performance equipment offers numerous cost-saving benefits for businesses.

While the upfront cost may be higher, the long-term savings in tool replacements, maintenance, and downtime make tungsten carbide an economical choice.

By improving tool performance, enhancing equipment efficiency, and lowering operational costs, tungsten carbide tips provide a high return on investment (ROI), helping companies maximize their budgets and improve their bottom line.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.