مقدمة

As factories and industries become more modern and connected, cutting tools must also evolve. Tungsten carbide cutting tools are already popular in many industries. But now, they are playing an even bigger role in advanced manufacturing.

In this article, we’ll explore the future of tungsten carbide tools, how they are being improved with new technology, and how they will support smart, fast, and sustainable production.

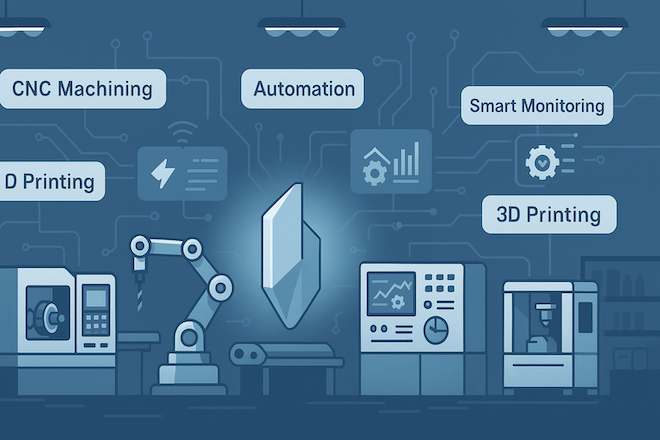

What Is Advanced Manufacturing?

Advanced manufacturing uses modern methods, smart machines, and digital systems to make products. It includes technologies like:

تصنيع باستخدام الحاسب الآلي

Robotics

Automation

IoT (Internet of Things)

AI and data monitoring

3D printing

These systems help companies:

Save time

Reduce waste

Make more accurate parts

Lower costs

Be more flexible in production

To keep up, manufacturers need tools that are strong, reliable, and precise—like أدوات القطع المصنوعة من كربيد التنغستن.

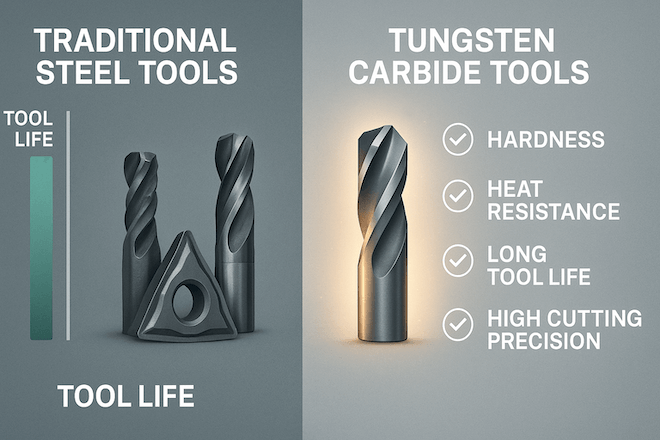

Why Are Tungsten Carbide Tools Still the Top Choice?

Tungsten carbide is made from tungsten and carbon, forming an extremely hard compound. Its advantages include:

عالي صلابة والقوة

Wear and heat resistance

عمر خدمة طويل

Sharp edges for precision cuts

These tools are perfect for cutting steel, aluminum, titanium, composite, and even wood in high-speed machines.

في إعادة, we provide a wide range of tungsten carbide cutting tools that are trusted in more than 50 countries.

Explore our top tools:

Future Trends in Tungsten Carbide Cutting Tools

Let’s look at how tungsten carbide tools are being improved to meet the needs of advanced manufacturing.

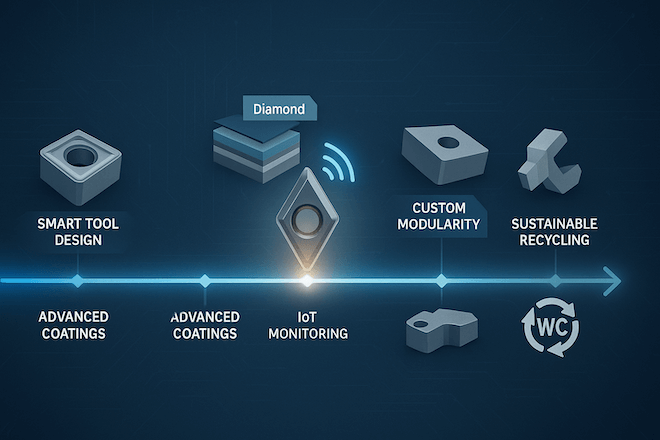

1. Smarter Tool Design

New designs are being developed to improve:

Chip evacuation

سرعة القطع

تشطيب السطح

Tools now include internal coolant holes, multi-flute geometry, and hybrid profiles for faster machining and longer life.

2. Coatings and Surface Technology

Modern carbide coatings make carbide tools last even longer. Popular coatings include:

TiAlN (نيتريد التيتانيوم والألومنيوم)

AlCrN (Aluminum Chromium Nitride)

Diamond coatings for non-metal machining

These coatings increase heat resistance, reduce friction, and help tools work better at high speeds.

👉 Learn more about coatings in our tungsten carbide technical glossary على www.retopz.com

3. Tool Monitoring and Data Feedback

In smart factories, tools are being paired with sensors and IoT systems to track:

Tool wear

Cutting forces

Vibration

Temperature

This data helps machines know when to change a tool before failure. It also helps improve future cutting conditions.

4. Tool Customization and Modularity

In the future, more factories will ask for custom-made carbide tools that fit their exact machines and materials. Benefits of customization:

وقت تعطل أقل

Better cutting performance

Lower total cost per part

في إعادة, we offer full support for custom carbide tool design.

5. Sustainability and Tool Recycling

Tungsten carbide is 100% recyclable. In advanced factories, tool recycling is part of a circular economy. Manufacturers save money and reduce environmental impact by:

Sending back worn tools

Reprocessing the material

Making new tools with recycled carbide

👉 Retop supports green manufacturing through durable tools and material recycling. See more in our post: كيف تدعم أدوات القطع المصنوعة من كربيد التنغستن التصنيع المستدام

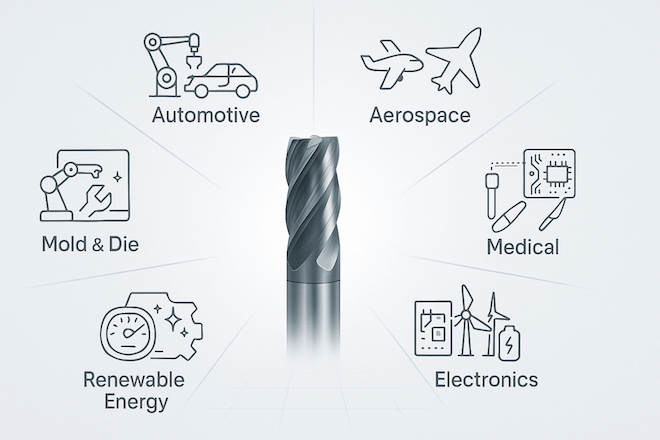

Key Industries Leading the Future

Tungsten carbide tools are critical in advanced manufacturing across industries:

| صناعة | Tool Applications |

|---|---|

| السيارات | Engine blocks, transmission parts, brake rotors |

| الفضاء الجوي | Titanium parts, turbine blades, aircraft frames |

| طبي | Surgical tools, implants, precision drilling |

| الالكترونيات | PCB routing, micro-machining, connector slots |

| قوالب وقوالب | Injection molds, precision cavities |

| Renewable Energy | Wind turbine parts, battery enclosures |

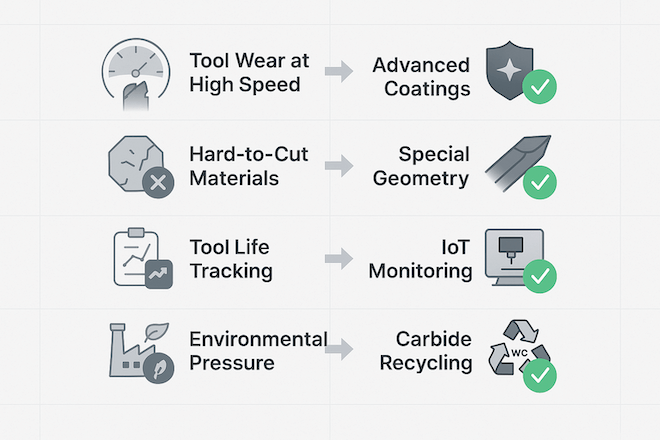

Challenges and Solutions

Even the best tools have challenges. Here’s how tungsten carbide technology is solving them:

| تحدي | حل |

|---|---|

| Tool wear at high speeds | New coatings and cooling methods |

| Hard-to-cut materials | Custom geometries, stronger carbide grades |

| Tool life tracking | Sensors and smart tool holders |

| Sustainability goals | Recycling programs and long-life designs |

What Retop Is Doing for the Future

At Retop, we are always working on next-generation carbide tools. Here’s how we support the future of machining:

High-performance carbide grades

Precision grinding and finishing

Customized geometries

Application-specific tool development

Rapid prototyping for custom tools

Sustainable sourcing and recycling

We help manufacturers stay competitive in industries that demand high accuracy, speed, and reliability.

خاتمة

The future of tungsten carbide cutting tools is smarter, faster, and more sustainable. As advanced manufacturing grows, carbide tools will continue to be the foundation of high-performance machining.

Whether it’s aerospace, automotive, or medical manufacturing, choosing the right cutting tool can improve product quality, machine uptime, and environmental performance.

If you’re ready to move forward with the next generation of carbide tools, contact Retop اليوم.