In the world of industrial cutting, efficiency, precision, and durability are essential. Tungsten carbide tips play a crucial role in achieving these qualities in industrial saws and blades.

These tips are made from a material that is known for its صلابة, مقاومة التآكل, and heat tolerance, making them ideal for cutting through a variety of tough materials.

This blog will explore the role of tungsten carbide tips in industrial saws and blades, the benefits they bring, and how they improve cutting operations.

Introduction to Tungsten Carbide Tips in Cutting Tools

Tungsten carbide is a composite material made from tungsten and carbon. It is extremely hard and durable, making it ideal for applications that involve heavy wear and abrasion.

Tungsten carbide tips are small, tough pieces of this material that are attached to cutting tools like industrial saws and blades.

These tips maintain their sharpness for a longer time compared to traditional materials, reducing the need for frequent replacements and improving overall cutting performance.

Why Tungsten Carbide Tips Are Used in Industrial Saws and Blades

One of the main reasons tungsten carbide tips are used in industrial saws and blades is their exceptional hardness.

Tungsten carbide is one of the hardest materials available, which allows the tips to cut through tough materials like metals, concrete, and stone without losing their sharpness.

The wear resistance of tungsten carbide tips ensures that they last much longer than other materials, reducing the frequency of blade replacements and maintenance.

مقاومة الحرارة

During cutting, friction generates heat, which can cause traditional cutting tools to wear out quickly.

Tungsten carbide tips excel in heat resistance, meaning they can withstand the high temperatures generated during cutting without losing their strength or becoming deformed.

This makes them especially useful in high-speed cutting operations where heat is a significant concern.

Precision and Cutting Efficiency

Industrial saws and blades equipped with tungsten carbide tips are known for their precision.

ال صلابة of the tips ensures that the blades maintain a sharp edge for longer, leading to cleaner cuts with fewer defects.

This is crucial in industries where precision cutting is essential, such as in metalworking, woodworking, and construction.

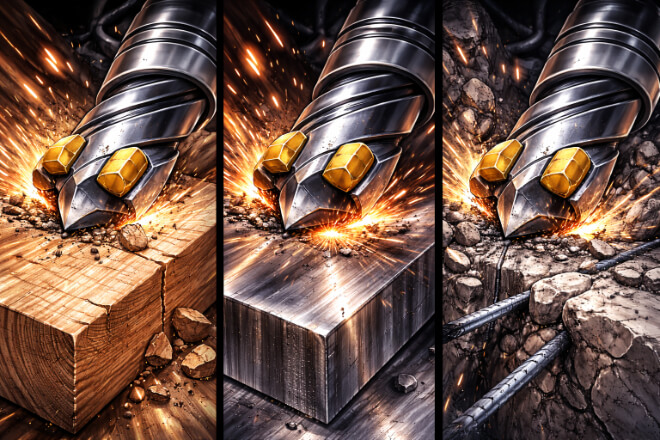

Applications of Tungsten Carbide Tips in Industrial Saws and Blades

1). Woodworking Saws and Blades

In woodworking, saws and blades equipped with tungsten carbide tips are commonly used to cut through hard and soft woods.

The durability of tungsten carbide ensures that the blades stay sharp even after extended use, leading to consistent performance.

Tungsten carbide-tipped blades also help reduce the need for frequent sharpening, allowing for longer cutting periods with minimal interruptions.

2). Metal Cutting Saws

Tungsten carbide tips are widely used in metal cutting saws because of their ability to handle hard metals like steel, aluminum, and brass.

These tips provide the necessary durability and sharpness to cut through tough metal without wearing down quickly.

Tungsten carbide-tipped metal cutting blades are essential in manufacturing processes where high precision and efficiency are critical.

3). Concrete and Stone Cutting Saws

When it comes to cutting concrete, stone, or other hard materials, tungsten carbide tips are the best choice.

The tips’ صلابة و مقاومة التآكل allow the blades to cut through these materials more efficiently than traditional blades.

This makes tungsten carbide-tipped saws indispensable for construction, mining, and demolition projects.

Benefits of Tungsten Carbide Tips in Industrial Saws and Blades

1). Increased Tool Life

One of the key benefits of tungsten carbide tips is their extended tool life.

Due to their صلابة و مقاومة التآكل, these tips can last much longer than standard saw blades, reducing the need for frequent replacements and maintenance.

This leads to cost savings in the long term, as companies spend less on replacement tools and downtime.

2). Improved Cutting Performance

Tungsten carbide tips improve the cutting performance of saws and blades by ensuring that the cutting edge remains sharp for longer periods. This leads to smoother cuts, reduced vibrations, and improved accuracy.

The ability to cut through tough materials more efficiently also enhances overall productivity, as less time is spent on retooling and sharpening.

3). Cost-Effectiveness

Although tungsten carbide-tipped blades may have a higher initial cost, their longer lifespan and improved cutting performance make them a more cost-effective option in the long run.

The reduced need for tool replacements and maintenance means that companies can achieve greater productivity at a lower overall cost.

Challenges and Considerations

1). Initial Cost

Tungsten carbide-tipped saws and blades can be more expensive upfront compared to those made from other materials.

However, this initial cost is typically offset by the longer tool life and reduced maintenance requirements, making them a worthwhile investment for businesses.

2). Brittleness

While tungsten carbide is incredibly hard, it can also be brittle.

If the tool is subjected to extreme stress, such as when hitting a hard object or encountering an unexpected impact, the tips can chip or break.

Therefore, it’s important to handle tungsten carbide-tipped tools carefully to avoid damage.

3). Maintenance and Care

While tungsten carbide tips require less maintenance than traditional blades, proper care is still essential for maximizing their lifespan.

Regular cleaning and proper storage can help prevent damage and ensure that the blades maintain their sharpness and performance over time.

خاتمة

Tungsten carbide tips play a crucial role in improving the performance, efficiency, and durability of industrial saws and blades.

Their hardness, wear resistance, and heat resistance make them ideal for cutting through tough materials with precision and minimal downtime.

While the initial cost may be higher, the long-term benefits, including extended tool life and improved cutting performance, make them a cost-effective choice for industrial applications.

By investing in tungsten carbide-tipped tools, companies can improve their productivity, reduce maintenance costs, and ensure high-quality cutting results.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.