When companies buy حلقات ختم الكربيد, they often focus on the initial purchase price. However, the true cost of these components goes far beyond that.

For decision-makers in industries like النفط والغاز, chemical processing, or mechanical equipment manufacturing, the total cost of ownership (TCO) is what truly defines long-term value.

This article explains how repairability and a smart lifecycle strategy can reduce the total cost of ownership of tungsten carbide seal rings.

With the right approach, companies can extend part life, minimize downtime, and improve overall equipment efficiency.

What Total Cost of Ownership Really Means

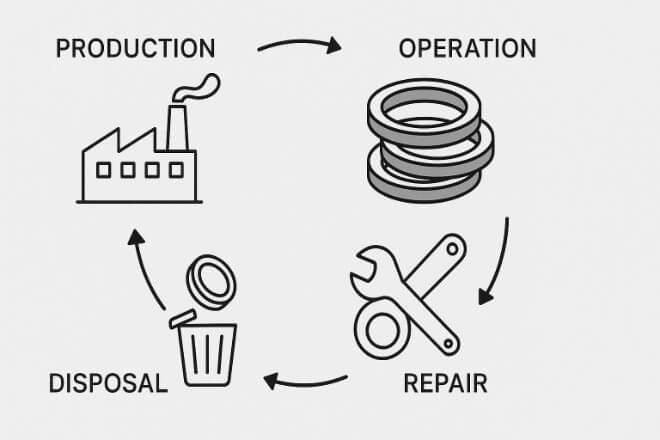

The total cost of ownership (TCO) includes all expenses related to the purchase, operation, maintenance, and replacement of a product during its lifetime.

ل حلقات ختم الكربيد, this means more than the unit price. It covers:

Manufacturing and customization

Installation and removal

Maintenance and repair

Downtime costs during replacement

Disposal or recycling at the end of life

By understanding these cost factors, managers can make smarter purchasing and maintenance decisions that support both performance and budget goals.

The Hidden Costs of Seal Ring Failures

Even a small seal ring failure can lead to major operational problems. Leakage, vibration, and overheating often cause expensive downtime.

For example, in a pump or compressor, a worn carbide seal ring can stop the entire system until a new one is installed.

Many companies underestimate these hidden costs, which include:

Unplanned shutdowns

Labor and replacement expenses

Energy losses from inefficient sealing

Increased risk of secondary component damage

Investing in high-quality tungsten carbide seal rings with proper grade selection and precision finishing can greatly reduce these hidden costs over time.

Factors That Influence Lifecycle Costs

Several factors affect the lifecycle cost of a carbide seal ring:

| عامل | وصف | Impact on Cost |

|---|---|---|

| درجة المادة | Determines wear, corrosion, and temperature resistance | Higher grade can reduce replacement frequency |

| تشطيب السطح | Affects sealing efficiency and friction loss | Better finish lowers energy and wear costs |

| Operating Conditions | Pressure, temperature, and media type | Extreme conditions shorten lifespan |

| Maintenance Schedule | Regular inspection and re-lapping | Extends usable life |

| Repair Options | Ability to regrind or reuse | Reduces total replacement cost |

The Role of Repairability in Reducing TCO

Repairability is one of the most important but often overlooked factors in reducing ownership costs.

Many حلقات ختم الكربيد can be re-lapped, re-ground, or refurbished, returning them to like-new condition.

Key Benefits of Repairing Seal Rings:

40–70% cheaper than complete replacement

Shorter lead time compared to new production

Reduced waste and environmental impact

Consistent dimensional control after regrinding

When working with a trusted carbide component supplier, repair and inspection programs can become part of your lifecycle management strategy, significantly lowering total cost.

Planning a Lifecycle Strategy for Seal Rings

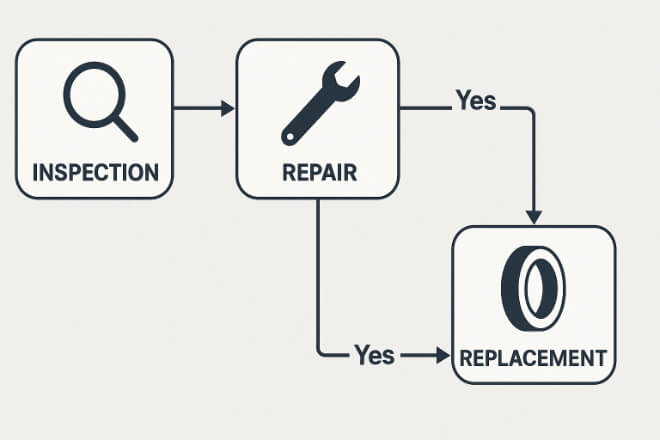

A lifecycle strategy ensures your equipment continues to perform with minimal unplanned downtime. It should include the following steps:

Baseline Evaluation – Inspect existing carbide seal rings for wear and record failure modes.

Predictive Maintenance – Use operation data (vibration, temperature, pressure) to predict wear before failure.

Repair vs Replace Decision – Create a clear rule for when rings should be re-lapped or replaced.

Supplier Partnership – Work with your manufacturer for ongoing inspection and material upgrades.

Lifecycle Cost Tracking – Keep data on total service time, repair frequency, and cost per hour of operation.

A well-structured lifecycle plan not only controls cost but also improves reliability and sustainability.

Comparing Repair and Replacement Costs

Let’s look at an example comparison between repairing and replacing carbide seal rings.

| Option | Average Cost (USD) | Lead Time | التأثير البيئي |

|---|---|---|---|

| Repair / Re-lap | $120–$180 | 1–2 weeks | Low (material reused) |

| New Replacement | $250–$350 | 3–5 weeks | High (new raw material used) |

While prices vary depending on size and grade, repairing usually saves 40–50% and reduces delivery time by half.

Extending Service Life Through Proper Handling

Even the best carbide seal rings can fail early if handled or installed incorrectly. To maximize service life:

Avoid dropping or impacting the rings during assembly.

Clean sealing faces thoroughly before installation.

Use correct torque and alignment when mounting.

Maintain clean lubrication to reduce friction.

Small actions in handling can greatly reduce wear and protect your investment.

Partnering with the Right Supplier

Choosing a reliable tungsten carbide seal ring manufacturer is part of controlling total cost. A strong supplier should provide:

Technical advice on grade selection and finish

In-house repair and re-lapping services

Fast turnaround for urgent replacements

Long-term cost and performance tracking

A supplier that understands your industry can help design a custom lifecycle plan, ensuring consistent performance and reduced ownership cost.

خاتمة

Understanding the total cost of ownership for carbide seal rings is essential for effective asset management. Instead of focusing only on price, consider repairability, service life, and lifecycle strategy.

Companies that integrate repair programs and data-driven maintenance reduce costs, improve reliability, and extend the useful life of their carbide components.

In today’s competitive market, smarter lifecycle management is not only about saving money — it’s about building sustainable operations and maximizing return on every investment.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.