When companies choose كرات كربيد التنغستن, they often focus on صلابة and durability. These are important, but one factor that many overlook is size.

The diameter of a tungsten carbide ball is not just a measurement on paper—it directly affects strength, مقاومة التآكل, and long-term performance.

For decision-makers in industries like النفط والغاز, السيارات, chemical, and الفضاء الجوي, choosing the right ball size can mean the difference between smooth operation and costly downtime.

In this guide, we explain why size matters, how it changes performance, and what to consider before making a purchase.

What Makes Tungsten Carbide Balls Unique

Tungsten carbide is a compound of tungsten and carbon, often combined with cobalt or nickel as a binder.

The material is nearly as hard as diamond and can handle extreme stress.

Main qualities include:

استثنائي صلابة

عمر خدمة طويل

Ability to hold shape under pressure

Because of these traits, tungsten carbide balls are trusted in precision tools, heavy-duty machinery, and critical systems.

But these advantages only deliver full value when the correct ball size is chosen.

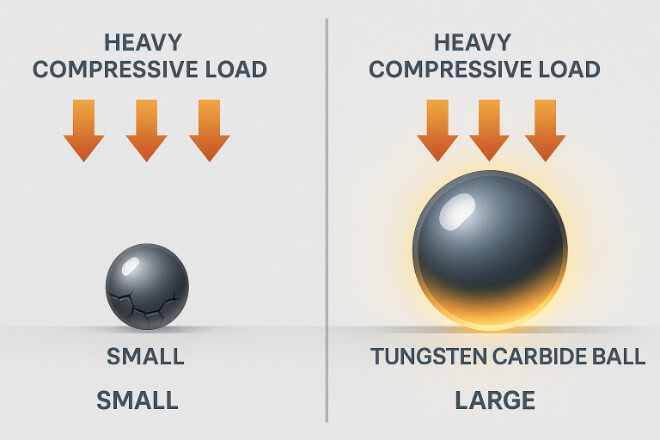

How Ball Size Influences Strength

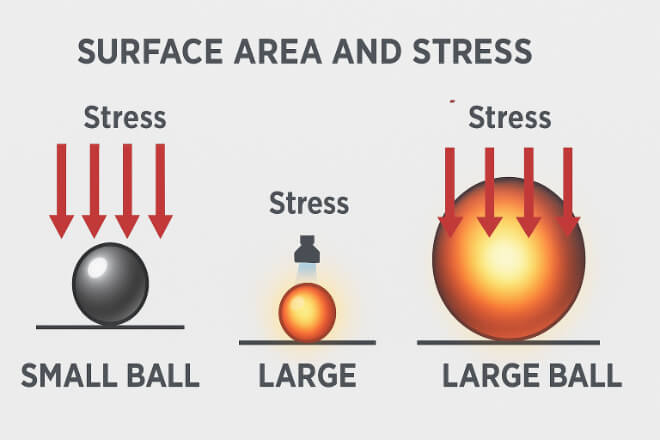

The relationship between ball size and strength is simple: larger surface area spreads out stress, smaller size concentrates stress.

Small balls are excellent for lightweight precision tasks but can deform faster under heavy loads.

Large balls handle higher forces and resist cracking but may reduce speed or increase friction in certain systems.

على سبيل المثال:

A 1 mm ball in a flowmeter gives fine measurement accuracy.

A 20 mm ball in a valve provides sealing strength against high fluid pressure.

This difference shows that size is not just a design choice—it is a performance factor.

Load Capacity and Ball Size

The ability of a ball to carry weight depends heavily on size. Bigger balls can take on more pressure because the force is spread across a wider contact area.

Example comparison:

Small ball: Higher stress concentration, more risk of fatigue.

Large ball: Lower stress per surface unit, better durability.

In bearings, this means smaller balls give higher rotational speed but lower load capacity, while larger balls give strength but reduce maximum speed.

Decision-makers need to balance speed versus strength depending on the system.

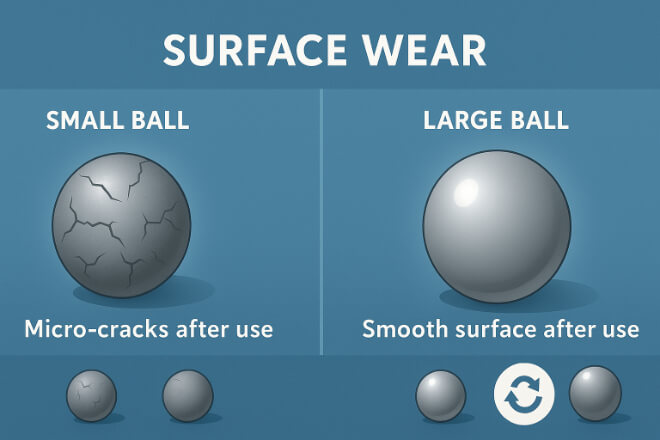

Wear Resistance and Ball Size

Tungsten carbide is already resistant to wear, but size plays a role too.

Smaller balls often show faster surface fatigue because the pressure is concentrated.

Larger balls distribute force better, reducing wear over time.

That is why industries with heavy fluids or abrasive particles—such as mining or oil drilling—prefer larger carbide balls.

In contrast, precision labs and flowmeters rely on smaller balls for accuracy.

Real-World Applications Where Size Matters

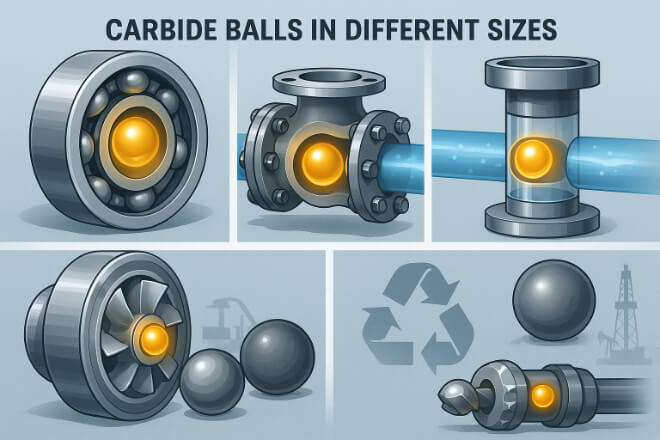

1). Bearings

Ball size controls both strength and speed. Small balls are used in high-speed instruments, while larger ones support heavy loads in engines or turbines.

2). Valves

Valve systems that handle gases or liquids under high pressure often use larger balls for tight seals. The wrong size can cause leaks and downtime.

3). Flowmeters

Small balls provide smooth movement and precise measurement in flowmeters.

They allow sensitive adjustments where accuracy is more important than strength.

4). النفط والغاز حفر

Large carbide balls are common in drilling motors and valve systems. Their size helps withstand abrasive mud and high impact.

5). السيارات و الفضاء الجوي

Both small and medium-sized carbide balls are used in engines, fuel systems, and turbochargers.

Size choice depends on whether speed, strength, or durability is the priority.

Choosing the Right Size: Key Factors

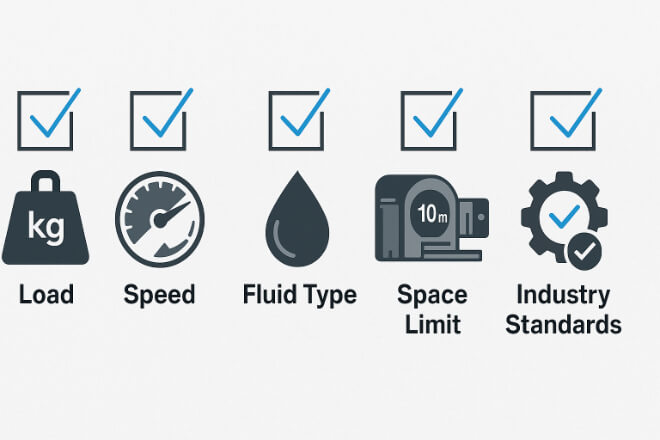

When selecting carbide ball size, decision-makers must consider:

Load Conditions – What pressure or weight will the ball handle?

Speed Needs – Does the system prioritize fast rotation or heavy strength?

Fluid or Gas Type – Corrosive or abrasive media require larger, tougher balls.

Space Limits – Equipment design may restrict the maximum ball size.

Industry Standards – Certain industries have set size ranges for safety.

Choosing the wrong size can result in premature failure or inefficiency.

Best Practices for Using Tungsten Carbide Balls of Any Size

To make sure carbide balls deliver their maximum value:

Install Correctly: Use proper seating and alignment.

Use Proper Lubrication: Reduces stress, whether the ball is small or large.

Inspect Regularly: Look for flat spots, cracks, or wear signs.

Avoid Contaminants: Dust and dirt increase stress on smaller balls especially.

Plan Replacement: Keep the right sizes in stock for fast replacement.

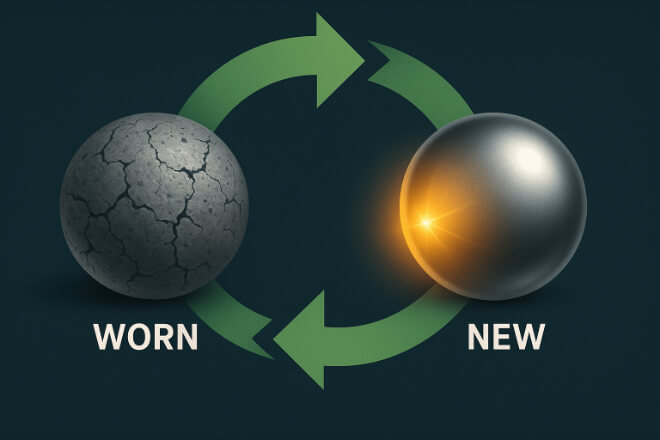

Maintenance and Replacement Strategies

Even though tungsten carbide lasts longer than steel, it still needs care.

Inspection Frequency: In critical industries, check size and condition every few weeks.

Signs of Failure: Inaccurate readings, valve leakage, or noisy bearings.

Replacement Policy: Always replace with the same size—changing size can damage the system.

Recycling Advantage: Old carbide balls can be recycled, lowering long-term cost.

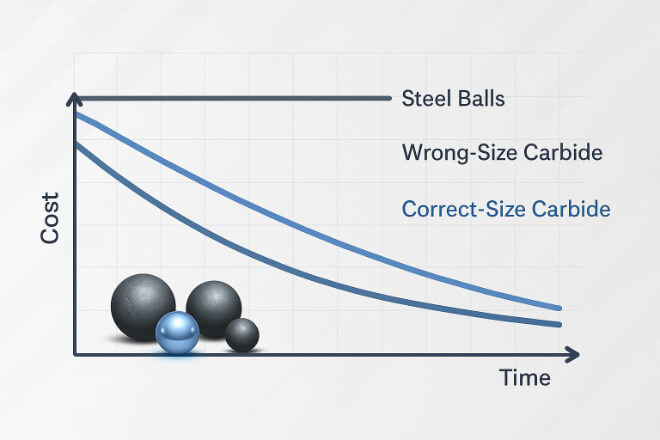

Cost Impact of Ball Size Decisions

Ball size does not only affect technical performance but also financial outcomes.

Correct Size = Savings: Longer tool life, fewer breakdowns, more uptime.

Wrong Size = Costs: Increased maintenance, downtime, and part failures.

For decision-makers, choosing the right size brings a clear return on investment.

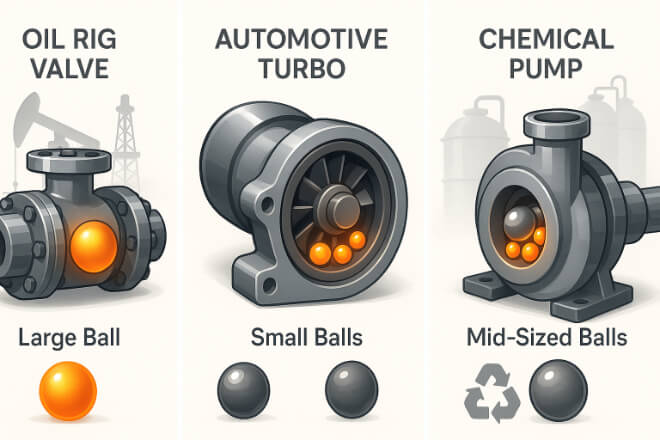

دراسات الحالة

1). Oilfield Valves

A drilling company switched from medium to larger carbide balls in valve systems. Result: fewer leaks and longer tool life.

2). Automotive Bearings

A car manufacturer used smaller balls in turbochargers. The result was higher speed and improved efficiency without sacrificing safety.

3). Chemical Pumps

Using mid-sized balls gave the best balance—strong enough for corrosive fluids, yet precise enough for flow control.

How to Source the Right Size

To ensure the right ball size for strength and performance:

Work with Experienced Suppliers: They can recommend correct diameters.

Ask for Technical Support: Good suppliers provide load and size charts.

Check Certifications: ISO standards ensure consistency.

Look for Custom Options: Some applications need non-standard sizes.

Choose Local Stock: Fast delivery reduces downtime.

For supplier directories and industry references, visit Retopz.com.

خاتمة

Tungsten carbide ball size is a key factor in strength. From tiny balls in flowmeters to large ones in drilling tools, the diameter directly influences performance, durability, and cost efficiency.

For decision-makers, understanding the link between ball size and strength ensures better system design, smoother operation, and smarter investments.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.