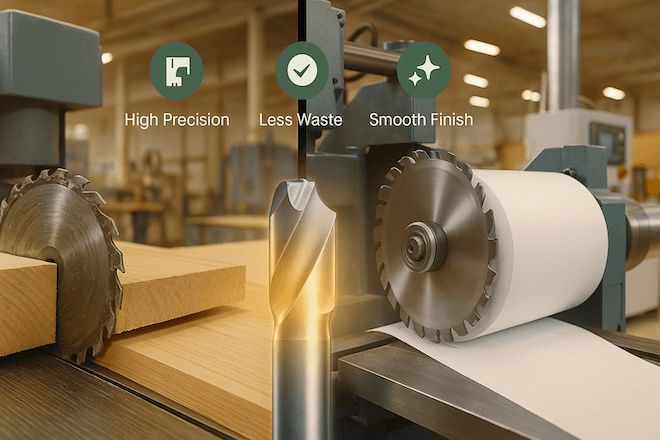

لماذا يُعد أداء أدوات القطع أمرًا مهمًا في صناعات الخشب والورق

في قطاعي النجارة وقطع الورق، يزداد الطلب على السرعة والدقة وتقليل الهدر أكثر من أي وقت مضى. تُستخدم أدوات القطع يوميًا لتشكيل الخشب، وتشذيب الألواح، وتقطيع لفات الورق، والحصول على تشطيبات أنيقة. إذا لم تكن الأدوات حادة أو متينة، فقد يؤدي ذلك إلى قطع رديء الجودة، وهدر كبير للمواد، وتعطل الآلة.

أدوات قطع كربيد التنغستن تساعد في حل هذه المشاكل. مقارنةً بأدوات الفولاذ العادية، تتميز أدوات الكربيد بثباتها لفترة أطول، ومقاومتها للتآكل، وأدائها الممتاز حتى مع المواد اللينة أو الكاشطة مثل ألواح MDF أو الألواح المصفحة.

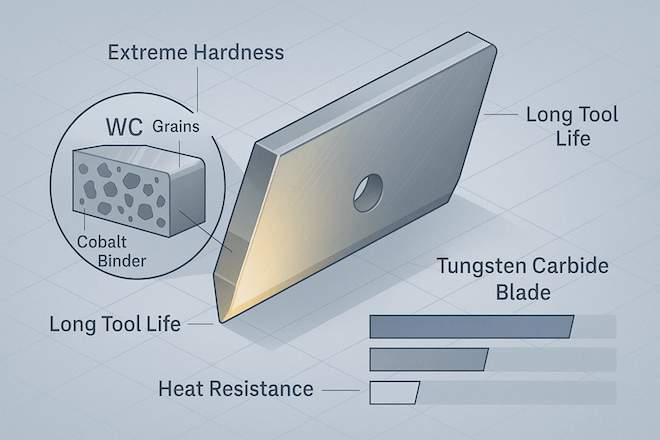

ما هو كربيد التنغستن؟

كربيد التنغستن مادة تُصنع من خلال دمج التنغستن (معدن شديد الصلابة) مع الكربون. والنتيجة مادة شديدة الصلابة ومقاومة للتآكل، أقوى بكثير من الفولاذ. وهو مثالي لأدوات القطع لأنه يحافظ على حافته لفترة طويلة، حتى بعد ساعات طويلة من الاستخدام.

في أعمال النجارة وقطع الورق، تعتبر هذه المتانة ضرورية. شفرات كربيد التنغستن يمكنها قطع الأخشاب الأكثر صلابة ومنتجات الورق الطبقي بسهولة، بينما تدوم لفترة أطول بكثير من الأدوات التقليدية.

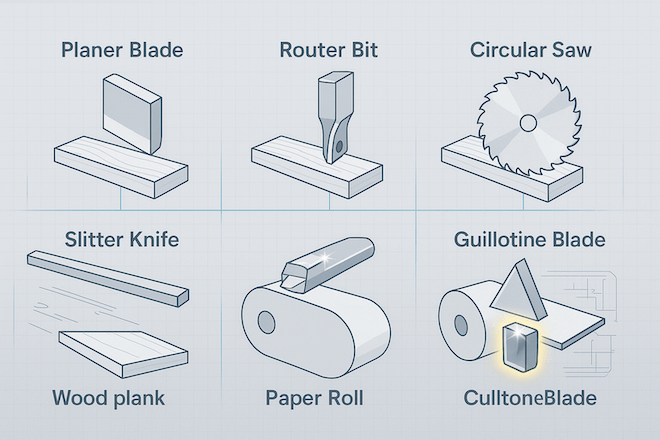

التطبيقات الشائعة في صناعات الخشب والورق

تُستخدم أدوات كربيد التنغستن في العديد من الطرق في أعمال النجارة وقطع الورق:

النجارة:

شفرات التخطيط للأسطح الملساء

بتات التوجيه لتشكيل الحواف

شفرات المنشار لقطع الأخشاب الصلبة والألواح متوسطة الكثافة

إدراجات تيرنر لتشكيل المخرطة

قص الورق:

سكاكين التقطيع لقص لفات الورق بسرعة عالية

شفرات القص لقطع دقيقة

شفرات المقصلة لقطع المكدس

يجب أن تعمل هذه الأدوات تحت الاستخدام المستمر، والسرعات العالية، والتحملات الضيقة.

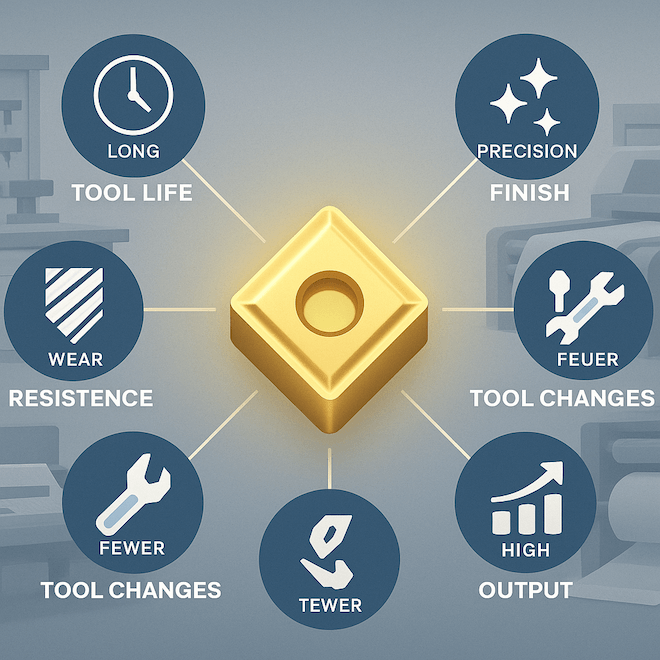

فوائد استخدام أدوات القطع المصنوعة من كربيد التنجستن

يقدم استخدام أدوات القطع المصنوعة من كربيد التنغستن العديد من الفوائد الرئيسية لهذه الصناعات:

عمر أطول للأداة يقلل من تغيير الأدوات ووقت التوقف عن العمل

دقة القطع الأفضل تضمن حواف نظيفة واحترافية

مقاومة عالية للتآكل تعني أداءً أفضل مع المواد الصلبة

انخفاض تكلفة التشغيل لأن الأدوات تدوم لفترة أطول وتعمل بشكل أفضل

تحسين الإنتاجية بسبب تقليل التوقفات اللازمة لشحذ الأدوات أو استبدالها

تساعد هذه المزايا الشركات المصنعة على تحقيق أهداف الإنتاج العالية مع الحفاظ على الجودة الثابتة.

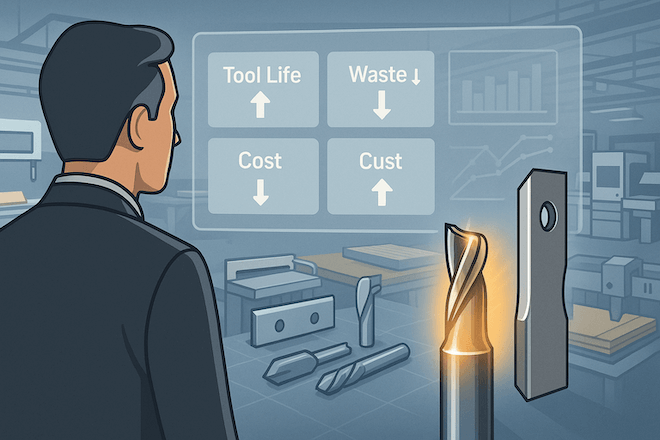

لماذا يختار صناع القرار كربيد التنغستن

بالنسبة للمديرين وصانعي القرار، يؤثر اختيار الأدوات بشكل مباشر على التكلفة والكفاءة ورضا العملاء. تساعد أدوات كربيد التنغستن على تقليل:

وقت صيانة الأداة

نفايات المواد من الجروح السيئة

تآكل المعدات بسبب الأداء الضعيف

توقفات غير مخطط لها

من خلال الاستثمار في أدوات الكربيد، غالبًا ما تشهد الشركات عوائد سريعة من خلال تدفق الإنتاج الأفضل والمشكلات الأقل في أرضية المتجر.

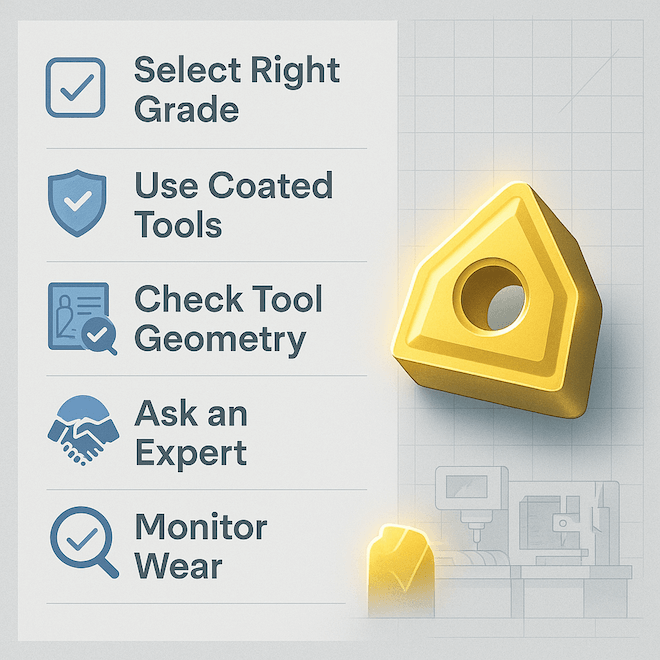

نصائح لاختيار أداة الكربيد المناسبة

ليست كل أدوات الكربيد متشابهة. إليك بعض النصائح للحصول على أفضل النتائج:

اختر الصحيح درجة الكربيد للمواد

يستخدم أدوات مطلية لتحسين الحياة والأداء

قم بمطابقة هندسة الأداة مع عملية القطع

العمل مع الموردين الموثوق بهم مثل Retop لتصميم الأدوات المخصصة

راقب تآكل الأداة بانتظام للحفاظ على جودة القطع

خاتمة

نجارة و قص الورق تتطلب المصانع الحديثة أدوات عالية الجودة وطويلة الأمد. توفر أدوات القطع المصنوعة من كربيد التنغستن المتانة والدقة والكفاءة التي تحتاجها. سواءً كان الأمر يتعلق بتشكيل أثاث خشبي فاخر أو تقطيع لفات ورق ضخمة، فإن هذه الأدوات تضمن سلاسة عمل الآلات وجمال مظهر المنتجات.

لتحقيق نجاح طويل الأمد، يُعد اختيار شريك الأدوات المناسب أمرًا بالغ الأهمية. تعرّف على المزيد حول الحلول عالية الجودة على www.retopz.com.