البيئات شديدة البرودة والتبريد - مثل محطات الغاز الطبيعي المسال (LNG)، الفضاء الجوي تتطلب مرافق الاختبار والمختبرات العلمية وأنظمة أعماق البحار حلولاً مانعة للتسرب يمكنها العمل بشكل موثوق في درجات حرارة منخفضة للغاية.

في هذه البيئات، تصبح المواد هشة، وتتصرف السوائل بشكل مختلف، وأي فشل يمكن أن يسبب توقفًا مكلفًا أو مخاطر تتعلق بالسلامة.

حلقات ختم كربيد التنغستن يعد خيارًا موثوقًا به للمضخات والضواغط والتوربينات العاملة في هذه الظروف القاسية.

تشرح هذه المقالة خصائصها ومزاياها وتطبيقاتها وأفضل الممارسات لصناع القرار.

تحديات الظروف المبردة والباردة للغاية

يؤدي التشغيل في درجات حرارة منخفضة تصل إلى -196 درجة مئوية (-320 درجة فهرنهايت) إلى خلق تحديات:

هشاشة المواد → يمكن أن تتشقق المعادن والبلاستيك أو تتشوه.

الانكماش الحراري → تتقلص المكونات، مما يؤدي إلى عدم المحاذاة.

مشاكل التزييت → تتكاثف السوائل أو تتجمد، مما يؤدي إلى زيادة الاحتكاك.

مخاطر فشل الختم → حتى التسريبات الصغيرة يمكن أن تسبب مواقف خطيرة.

تكاليف التوقف عن العمل → تعتبر الإصلاحات في المرافق المبردة مكلفة.

خصائص حلقات ختم كربيد التنغستن

كربيد التنغستن مركب من التنغستن والكربون، مرتبط بالكوبالت أو النيكل. خصائصه تجعله مثاليًا للبرد القارس:

عالي صلابة → يحافظ على القوة و مقاومة التآكل.

التمدد الحراري المنخفض → يقلل من التغيرات الأبعادية أثناء التبريد.

صلابة → يقاوم التشقق الناتج عن الصدمات الحرارية أو الاهتزاز.

مقاومة التآكل → يؤدي أداءً جيدًا مع السوائل المبردة مثل الغاز الطبيعي المسال أو الأكسجين السائل.

عمر خدمة طويل → يقلل من الصيانة والاستبدالات.

كربيد التنغستن المرتبط بالكوبالت مقابل كربيد التنغستن المرتبط بالنيكل

1) كربيد التنغستن المرتبط بالكوبالت

مقاومة أكبر للتأثير.

مناسب للمضخات والضواغط المعرضة للاهتزاز.

2) كربيد التنغستن المرتبط بالنيكل

أرقى مقاومة التآكل.

الأفضل للأنظمة المبردة التي تتعامل مع الأكسجين أو الهيدروجين أو السوائل الغنية بالمواد الكيميائية.

المزايا مقارنة بمواد الختم الأخرى

| ميزة | كربيد التنغستن | سيراميك | فُولاَذ |

|---|---|---|---|

| صلابة درجات الحرارة المنخفضة | ممتاز | منخفض، هش | معتدل |

| مقاومة التآكل | ممتاز | معتدل | فقير |

| مقاومة التآكل | عالية (درجات النيكل) | جيد جدًا | قليل |

| الانكماش الحراري | قليل | معتدل | عالي |

| عمر الخدمة | طويلة الأمد | معتدل | قصير |

التطبيقات في البيئات المبردة والباردة

حلقات ختم كربيد التنغستن تستخدم على نطاق واسع في:

مضخات وضواغط الغاز الطبيعي المسال → ضمان نقل الغازات المسالة دون تسرب.

أنظمة الاختبار المبردة في مجال الطيران والفضاء → تحمل البرد الشديد أثناء اختبار الصواريخ أو الأقمار الصناعية.

المختبرات العلمية → الحفاظ على سلامة الختم في أنظمة النيتروجين السائل.

معدات أعماق البحار البحرية → مقاومة الضغط العالي ومياه البحر المتجمدة.

أنظمة وقود الهيدروجين → توفير ختم آمن لتطبيقات الطاقة النظيفة.

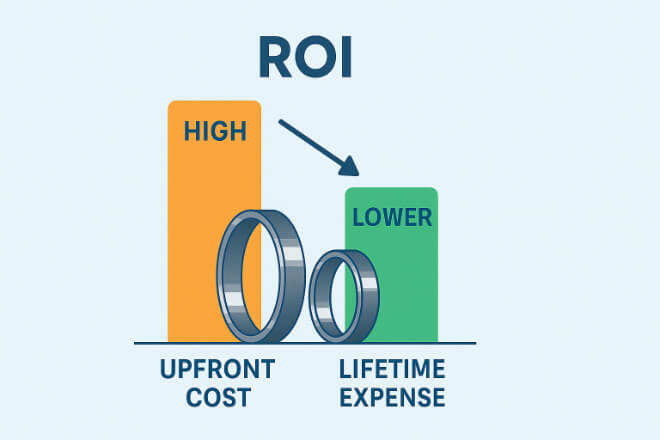

التكلفة مقابل القيمة طويلة الأجل

على الرغم من أن حلقات ختم كربيد التنغستن لها سعر أولي أعلى، فإنها:

تقليل وقت التوقف عن العمل عن طريق الاستمرار لفترة أطول.

انخفاض تكاليف الصيانة مع عدد أقل من عمليات الاستبدال.

حماية المعدات الهامة من التسربات والتلف.

توفير عائد استثمار أفضل في البيئات الباردة عالية المخاطر.

الفوائد البيئية والسلامة

منع التسرب → يقلل من خطر التلوث البيئي.

مواد قابلة لإعادة التدوير → يدعم أهداف الاستدامة.

تحسين الكفاءة → تستهلك الأنظمة الخالية من التسرب طاقة أقل.

أفضل الممارسات لاستخدام حلقات ختم كربيد التنغستن

مطابقة المجلد للبيئة → النيكل للسوائل المسببة للتآكل والتبريد العميق، والكوبالت للاهتزازات العالية.

استخدم تقنيات التثبيت المناسبة → تجنب الخدوش أو عدم المحاذاة.

فحص بانتظام → اكتشاف التآكل أو الضرر الناتج عن الانكماش في وقت مبكر.

العمل مع الموردين ذوي الخبرة → ضمان المواصفات الصحيحة للظروف المبردة.

تخطيط جداول الصيانة → تجنب عمليات الإغلاق غير المخطط لها في الأنظمة الحرجة.

أهم النقاط لصناع القرار

حلقات ختم كربيد التنغستن هي الخيار الأفضل للتطبيقات المبردة والباردة للغاية.

تمددها الحراري المنخفض، مقاومة التآكل، و صلابة منع التسربات والأضرار.

يؤدي اختيار المادة الرابطة الصحيحة (النيكل أو الكوبالت) إلى زيادة الموثوقية إلى أقصى حد.

يؤدي الاستثمار في كربيد التنغستن إلى تقليل وقت التوقف عن العمل والتكلفة والمخاطر البيئية.

خاتمة

في أنظمة التبريد العميق والباردة جدًا، تُعدّ موثوقية الختم أمرًا بالغ الأهمية. تُوفّر حلقات الختم المصنوعة من كربيد التنغستن أداءً لا يُضاهى، مما يضمن بقاء المضخات والضواغط والتوربينات خالية من التسرب حتى في الظروف القاسية.

بالنسبة لصناع القرار، يعد اختيار كربيد التنغستن استثمارًا استراتيجيًا في السلامة والكفاءة والاستدامة.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.