Rock drilling and exploration require tools that can endure harsh environments and break through tough rock formations. Tungsten carbide tips have become a crucial component in drilling tools used for these purposes.

Known for their durability, مقاومة التآكل, and exceptional صلابة, tungsten carbide tips improve drilling performance, reduce downtime, and extend tool life.

In this guide, we will explore how tungsten carbide tips are used in rock drilling, the benefits they offer, and how they contribute to efficient exploration operations.

What Are Tungsten Carbide Tips?

Tungsten carbide is a material composed of tungsten and carbon, offering high صلابة و resistance to wear.

Tungsten carbide tips are small, tough pieces of this material that are attached to drill bits, tools, and other cutting equipment.

These tips are designed to withstand extreme conditions, providing the necessary cutting power to drill through rock, soil, and other hard materials efficiently.

Why Tungsten Carbide Tips Are Essential for Rock Drilling and Exploration

أرقى صلابة and Durability

The primary reason tungsten carbide tips are used in rock drilling and exploration is their exceptional hardness.

Tungsten carbide is one of the hardest materials known, making it ideal for breaking through hard rock and other geological formations.

These tips maintain their sharpness longer than conventional materials, leading to improved drilling efficiency and a reduced need for frequent tool replacements.

Drilling through rock subjects tools to extreme stress and abrasion.

Tungsten carbide tips offer excellent wear resistance, meaning they can endure prolonged contact with rough, abrasive surfaces without degrading.

This results in longer tool life and reduced maintenance costs for drilling operations.

مقاومة الحرارة

During rock drilling, tools generate significant heat due to friction.

Tungsten carbide tips excel in heat resistance, enabling them to perform in high-temperature environments without losing their strength or hardness.

This is particularly useful in exploration, where drilling operations can occur deep underground where heat and pressure are significant factors.

Applications of Tungsten Carbide Tips in Rock Drilling

1). Rotary Drilling

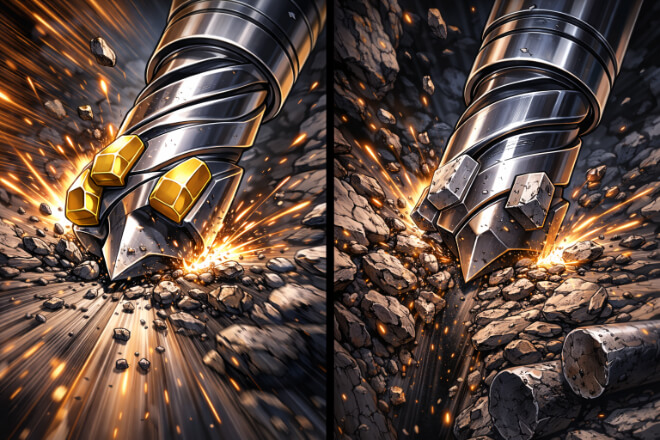

Rotary drilling is the most common method used in rock drilling. In this process, a drill bit equipped with tungsten carbide tips rotates and cuts into rock.

The hardness of the tips ensures that the drill bit can maintain sharpness and continue cutting through hard rock formations, enhancing overall drilling speed and efficiency.

2). Percussion Drilling

Percussion drilling involves rapid hammering to break through hard rock.

Tungsten carbide tips are often used in percussion drills because of their ability to withstand high-impact forces without breaking or losing their sharpness.

This makes them ideal for drilling through rock layers that are too tough for conventional drilling methods.

3). Exploration Drilling

In exploration drilling, the goal is to gather geological samples, often from deep underground.

Tungsten carbide tips are essential for ensuring that the drill bit can penetrate rock formations at varying depths and hardness levels.

The resilience of these tips ensures they perform consistently, even under harsh conditions, ensuring accurate samples are collected.

Benefits of Using Tungsten Carbide Tips in Rock Drilling and Exploration

1). Improved Drilling Speed

Tungsten carbide tips increase drilling efficiency by reducing the amount of time needed to penetrate hard rock.

Their sharpness and durability allow for faster drilling, which is crucial in both mining and exploration projects. The faster the drilling process, the less downtime, leading to increased productivity.

2). Longer Tool Life

Since tungsten carbide is highly resistant to wear, the tips last much longer compared to those made from softer materials.

This not only reduces the frequency of tool replacements but also cuts down on maintenance costs, making it a cost-effective choice in the long run.

3). Reduced Maintenance Costs

With longer-lasting tools, companies can save money on repairs and replacements.

Tungsten carbide tips help avoid the need for frequent servicing, allowing operations to stay on schedule and reducing the risk of unexpected downtime.

Challenges and Considerations When Using Tungsten Carbide Tips

1). Initial Cost

While tungsten carbide tips are highly durable, they can be more expensive than other materials.

The initial investment in tungsten carbide drill bits and tools may be higher, but the cost savings over time due to reduced maintenance and tool replacements often make up for the initial expense.

2). Tool Wear in Soft Rock

In some cases, tungsten carbide tips may wear more quickly in softer rock formations, as the material is not needed as much for cutting.

It is important to choose the right material for the specific drilling environment to ensure optimal performance.

3). Need for Specialized Equipment

Tungsten carbide tips may require specialized tools and machines for mounting and maintenance.

While they are highly effective, ensuring the proper setup and handling is essential for maximizing their performance.

خاتمة

Tungsten carbide tips are a vital component in rock drilling and exploration. Their superior hardness, wear resistance, and heat tolerance make them an excellent choice for drilling through tough rock formations.

By improving drilling speed, reducing downtime, and extending tool life, tungsten carbide tips contribute to more efficient and cost-effective exploration projects.

While the initial investment may be higher, the long-term benefits make tungsten carbide a worthwhile choice for companies involved in rock drilling operations.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.