Tungsten carbide (WC) wear parts are chosen for hard jobs: التعدين, النفط والغاز, تشغيل المعادن, pumps, and construction.

They last long because WC grains provide extreme صلابة and the metallic binder (usually cobalt or nickel) adds صلابة. Still, failures happen.

For decision-makers, knowing how and why tungsten carbide wear parts fail helps you reduce downtime, plan maintenance, and improve total cost of ownership (TCO).

This article explains the main failure mechanisms, what drives them, how to detect them, and what actions reduce risk.

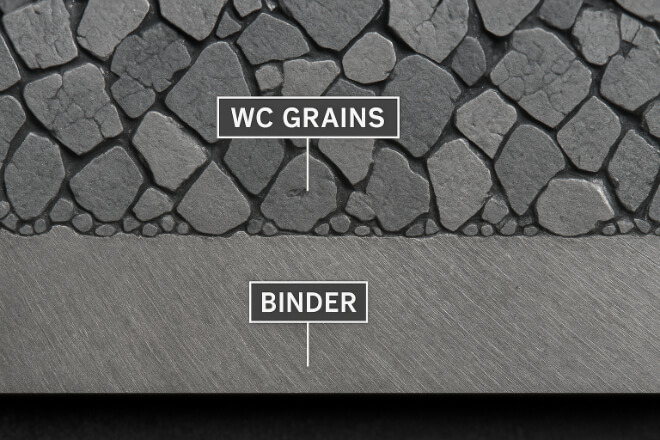

How Tungsten Carbide Wear Parts Are Built (Microstructure Basics)

Tungsten carbide wear parts are a composite. Hard WC grains are embedded in a ductile binder.

Grain size, binder content, and any alloying elements (Cr, Ni, etc.) shape performance.

Fine grains raise صلابة and abrasion resistance.

Coarser grains and higher binder improve صلابة ومقاومة التأثير.

Nickel or alloyed binders raise corrosion resistance but may change toughness.

Understanding this trade-off is the first step to preventing failure.

Operating Conditions That Drive Failure

Failures are rarely random; they follow operating conditions:

Particles (sand, rock, scale) → abrasion or erosion.

Chemicals / water → binder attack and corrosion.

Heat cycles → thermal fatigue and oxidation.

Shock / vibration → fracture and edge chipping.

Cyclic loads → mechanical fatigue.

Map your real environment to these drivers before selecting grade, geometry, and coating.

Abrasive Wear

Abrasive wear happens when hard particles slide or roll across the surface, cutting grooves and removing material.

It is common in drilling, crushing, and metal cutting.

Signals: Surface roughness rises, edges round off, size drifts.

Reduce risk: Choose harder, finer-grain WC; add wear-resistant coatings; use proper coolant/filtration; keep surfaces polished where possible.

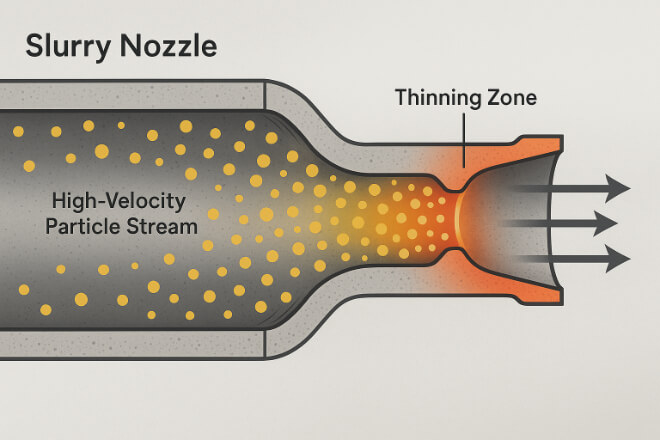

Erosive Wear

Erosion comes from high-velocity particles or slurry striking the surface at an angle. فوهات, الصمامات, and pump components see this daily.

Signals: Local thinning, directional scallops, performance drift (flow rate/pressure).

Reduce risk: Optimize flow geometry, switch to erosion-resistant grades, use dense coatings, minimize impingement angle, stabilize flow.

Corrosive Wear

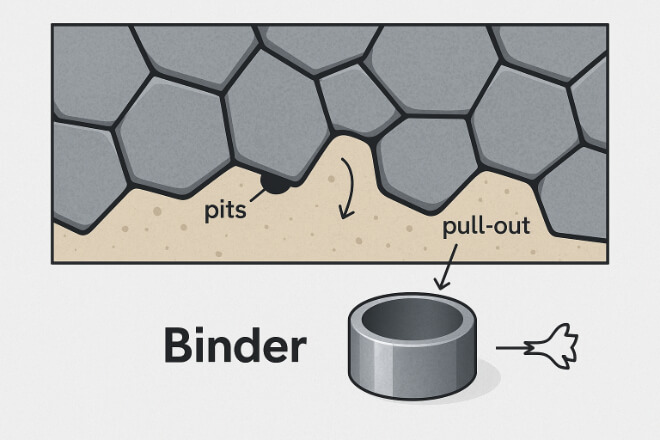

Corrosion mostly attacks the binder. Once the binder thins, WC grains lose support and get pulled out, accelerating wear.

Signals: Pitting, darkened binder areas, rapid roughening in wet/acidic service.

Reduce risk: Choose nickel-binder or alloyed binder; add anti-corrosion coatings; control pH and chlorides; avoid stagnant zones; consider binderless carbide for critical media.

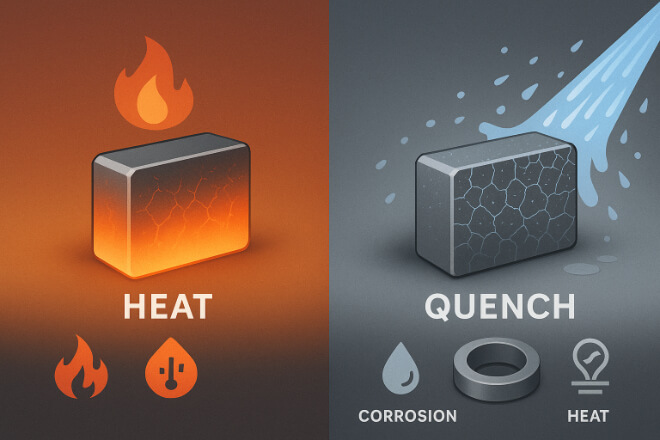

Thermal Fatigue and Thermal Shock

Fast heating and cooling cause micro-cracks that grow into larger cracks. Cutting tools, hot-work tools, and parts exposed to intermittent coolant are at risk.

Signals: Crack networks (“heat checking”), spalling, sudden edge failure.

Reduce risk: Tougher grades, controlled coolant application, steady thermal ramps, optimized duty cycles and speeds/feeds.

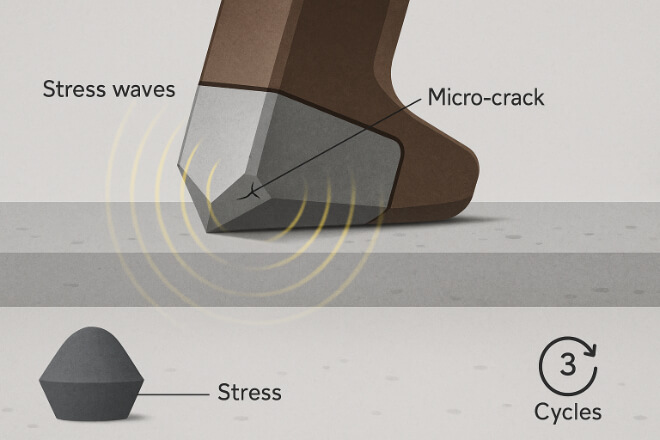

Mechanical Fatigue Under Cyclic Loads

Even loads below the static strength can cause failure when they repeat millions of times. Picks, crusher tools, and impact parts suffer here.

Signals: Delayed fracture after long service, cracks starting at stress raisers.

Reduce risk: Higher binder content for صلابة, generous radii/chamfers, eliminate sharp corners, reduce vibration, balance rotors and tooling.

Binder Depletion and Grain Pull-Out

Binder loss (by wear or corrosion) leads directly to grain pull-out. Pits form, edges dull, and wear accelerates.

Signals: Matte, pitted look; micro-cavities under magnification; rapid loss of size control.

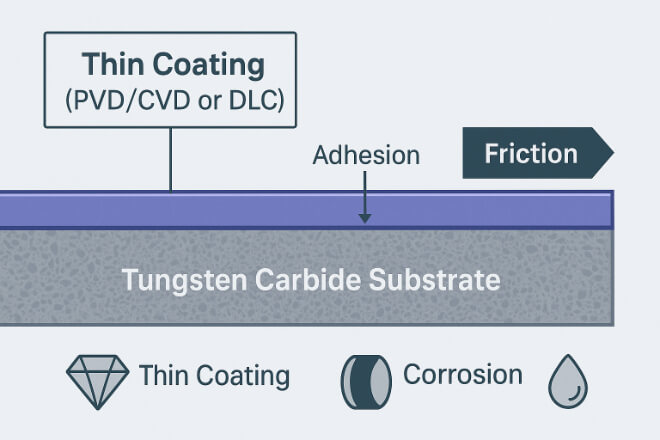

Reduce risk: Select grades with suitable binder type/content, polish contact zones, use seal-friendly finishes, apply dense PVD/CVD or diamond-like coatings where compatible.

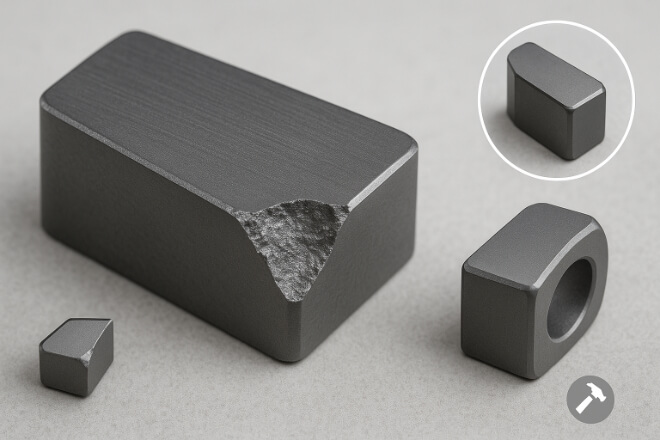

Edge Chipping and Bulk Fracture

If impact is high, geometry is sharp, or installation is misaligned, parts can chip or break.

Signals: Missing corners, step cracks, sudden tool loss.

Reduce risk: Tougher grades, edge prep (chamfer/radius), correct fixturing, align shafts and seats, avoid point loading, apply compressive surface states (where feasible).

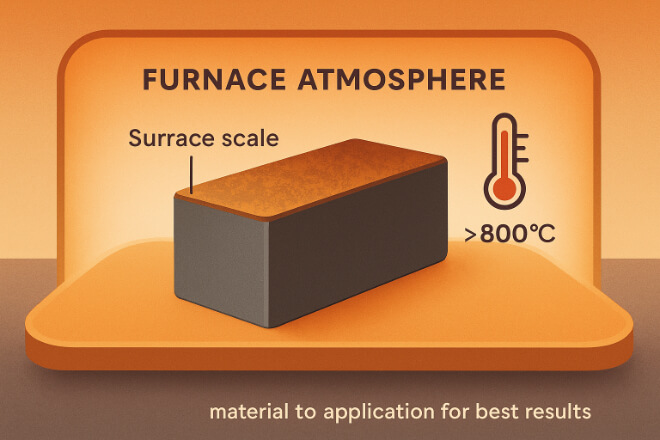

Oxidation and High-Temperature Damage

At high temperature and in oxygen, WC and binder can oxidize, reducing surface strength.

Signals: Scaling, color change, soft surface, oxide flakes.

Reduce risk: Protective coatings, inert or low-oxygen atmospheres, thermal shields, avoid prolonged over-temperature excursions.

Detecting Failure Early (Inspection & Metrics)

Early detection saves cost. Use simple controls:

Visual + loupe (10–20×): look for pits, cracks, and edge rounding.

Surface roughness: track Ra/Rz to spot early wear.

Mass/size checks: monitor critical diameters and thickness.

Vibration/flow/pressure: process signals that correlate with erosion or misalignment.

Failure records: log location, hours, media, temperature, and loads to see patterns.

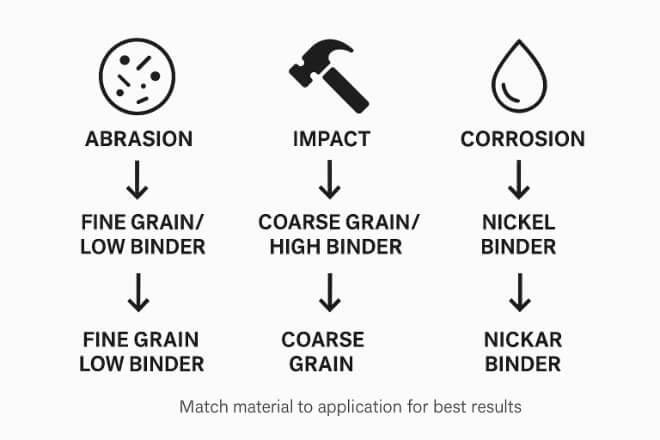

Preventing Failure: Design and Grade Selection

Design choices often decide life.

Match grade to risk: abrasion → fine grain/low binder; impact → coarser grain/higher binder; corrosion → nickel/Alloy-binder or binderless WC.

Geometry: remove sharp transitions; add fillets and edge prep; distribute load.

Fit and finish: control tolerances; polish where friction matters; avoid stress risers.

Process fit: confirm speed, load, and coolant match the material.

Surface Treatments and Coatings That Help

Coatings reduce wear and block corrosion/oxidation.

Hard PVD/CVD (TiN, TiCN, AlTiN, etc.) for abrasion and heat.

Diamond/DLC for sliding abrasion and low friction.

Chemical barriers for corrosive media (paired with nickel binders).

Ensure coating adhesion by using proper surface prep and compatible grades.

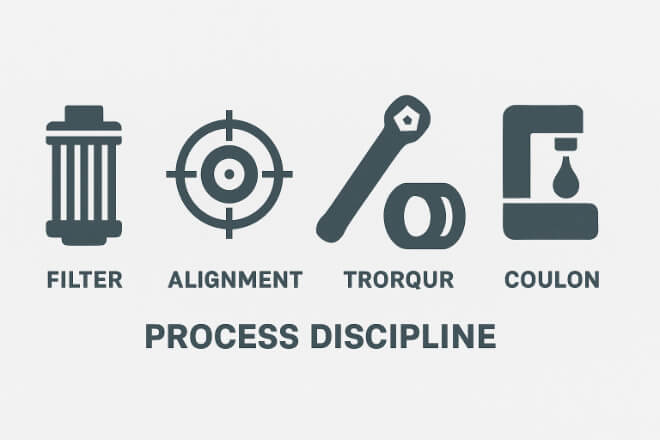

Operations and Maintenance Controls

Operator practice often defines outcome.

Keep filtration clean to remove abrasive fines.

Align and torque hardware to spec; avoid point loads.

Warm up hot-service parts; avoid sudden quench.

Swap parts on condition, not just time—use inspection data.

Train crews to spot early signs and report them.

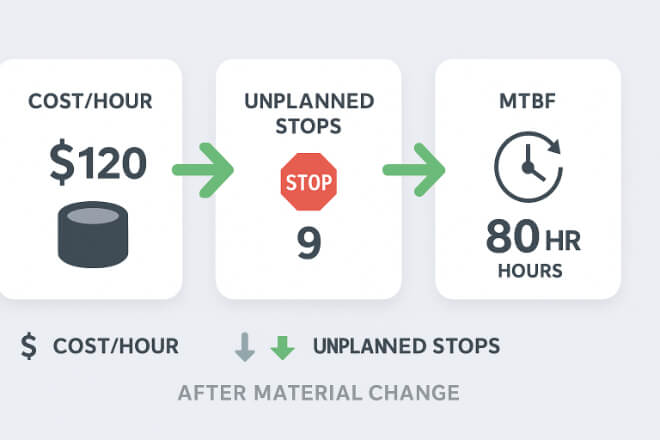

Economics: Downtime, TCO, and Decision Rules

Cheaper parts are costly if they fail early. Build a simple rule set:

If abrasion dominates, buy higher hardness and coatings.

If corrosion dominates, use nickel/Alloy-binder or barrier coatings.

If impact dominates, prioritize صلابة, edge prep, and geometry.

Track cost per operating hour and unplanned stops to guide future buys.

Failure Mechanisms at a Glance

| Failure Mechanism | Primary Driver | Early Signals | Prevention Focus |

|---|---|---|---|

| Abrasive Wear | Sliding/rolling hard particles | Grooves, edge rounding | Finer grains, hard coatings, filtration |

| Erosive Wear | High-velocity slurry/impingement | Local thinning, directional scallops | Flow geometry, dense coatings |

| Corrosive Wear | Binder attack by chemicals | Pitting, matte surface | Nickel/Alloy binder, barrier coatings |

| Thermal Fatigue/Shock | Rapid heat/cool cycles | Crack networks, spalling | Tough grades, coolant control |

| Mechanical Fatigue | Cyclic loads/vibration | Delayed fracture, root cracks | Higher binder, stress relief geometry |

| Binder Depletion | Wear/corrosion of binder | Pits, loose grains | Binder choice, polishing |

| Grain Pull-Out | Loss of grain support | التجاويف الدقيقة، قفزة الخشونة | تشطيب السطح، الطلاءات الكثيفة |

| التقطيع/الكسر | التأثير، عدم المحاذاة | شظايا الحواف، الزوايا المكسورة | إعداد الحافة، الدرجات الصعبة، المحاذاة |

| أكسدة | الأكسجين عالي الحرارة | مقياس، تغير اللون | الطلاءات الواقية/الغلاف الجوي |

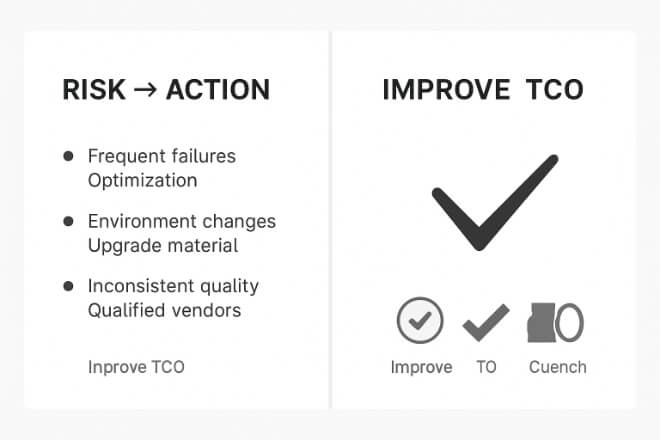

أهم النقاط لصناع القرار

حدد المخاطر السائدة لديك: التآكل، أو الحرارة، أو الاصطدام، أو الدورات.

حدد الدرجة والمادة الرابطة وحجم الحبوب لتتناسب مع هذا الخطر.

أضف الطلاءات حيث تحل حقًا المخاطر السائدة.

التحكم في الهندسة، والمحاذاة، والترشيح، والتبريد.

تتبع التكلفة لكل ساعة تشغيل والتوقفات غير المخطط لها - والشراء لتحسين هذه المقاييس.

خاتمة

تتعطل أجزاء كربيد التنغستن المقاومة للتآكل لأسباب معروفة. بربط ظروف التشغيل بالبنية الدقيقة والهندسة والطلاء وخطة الصيانة المناسبة، يمكنك إبطاء أي آلية عطل رئيسية.

النتيجة هي عمر أطول، ومفاجآت أقل، وتكلفة إجمالية للملكية أفضل. تعامل مع بيانات الأعطال كحلقة تغذية راجعة، وسيصبح كل استبدال أذكى من سابقه.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.