When machines run day after day in heavy industries like التعدين, النفط والغاز, تشغيل المعادن, or agriculture, the weakest link is often the part that wears down first.

To avoid frequent breakdowns, many companies depend on أجزاء تآكل كربيد التنغستن. These parts are known for their strength, hardness, and ability to resist wear better than steel or other common materials.

Behind every carbide wear part is a manufacturer whose skills, technology, and quality control directly affect performance.

For decision-makers, choosing the right tungsten carbide wear parts manufacturer is as important as selecting the material itself.

In this article, we’ll look at:

The role of carbide wear parts in modern industries.

What makes a good manufacturer.

How to evaluate suppliers.

Global leaders and regional specialists.

Why long-term partnerships matter.

Why Tungsten Carbide Wear Parts Are Essential

Tungsten carbide is a material made by combining tungsten and carbon powder with a binder, usually cobalt or nickel.

The result is a compound that is almost as hard as diamond but still has enough toughness to handle shocks and impacts.

Key advantages of أجزاء تآكل كربيد التنغستن include:

عالي صلابة: They resist scratching and deformation.

مقاومة التآكل: Longer life compared to steel or iron parts.

Heat resistance: Perform well even at high machining temperatures.

مقاومة التآكل: Many parts last longer in harsh chemical environments.

These features explain why manufacturers worldwide produce specialized carbide parts for industries that demand durability.

Common Types of Carbide Wear Parts

Manufacturers offer a wide range of products depending on customer needs. Typical parts include:

Cutting and drilling tools: Inserts, bits, and مطاحن نهاية.

التعدين tools: Buttons, picks, and crusher components.

Oil & gas parts: مقاعد الصمامات, sleeves, and pump plungers.

Industrial dies: For stamping, forming, and extrusion.

Agricultural tools: Tillage blades and plow tips.

نجارة and paper knives: Long-lasting cutting edges.

| فئة | Examples | Main Industries |

|---|---|---|

| أدوات القطع | Drills, inserts, end mills | Machining, metalworking |

| Mining Parts | Drill buttons, picks, wear plates | Mining, construction |

| النفط والغاز | Valve seats, sleeves, plungers | Energy, petrochemical |

| Industrial Dies | Stamping dies, extrusion dies | Automotive, aerospace |

| Agriculture | Plowshares, tillage tools | Farming, food processing |

| Wood/Paper | Saws, planer knives, slitters | Woodworking, packaging |

What Makes a Good Manufacturer?

Not all carbide parts are equal. The quality depends heavily on the manufacturer’s technology and processes. Good suppliers focus on:

Raw material quality: Using high-purity tungsten carbide powders and reliable cobalt/nickel binders.

Powder mixing and pressing: Ensuring even density and fewer weak points.

Sintering: Using controlled high-temperature furnaces for strength.

Precision grinding: Achieving tight tolerances and smooth finishes.

Coatings: Adding layers like TiAlN or DLC for extra performance.

Quality inspection: صلابة testing, microstructure analysis, and dimensional checks.

Manufacturers that invest in modern equipment and skilled engineers produce parts that last longer and perform better.

How to Evaluate a Manufacturer

When choosing a supplier, decision-makers should look beyond price. Important factors include:

Certifications (ISO 9001, ISO 14001, etc.).

Experience in serving your specific industry.

R&D capability for custom solutions.

Supply chain reliability and global delivery options.

Customer service with engineering support.

A manufacturer that understands your application can recommend the right carbide grade, binder, and coating, saving you money in the long run.

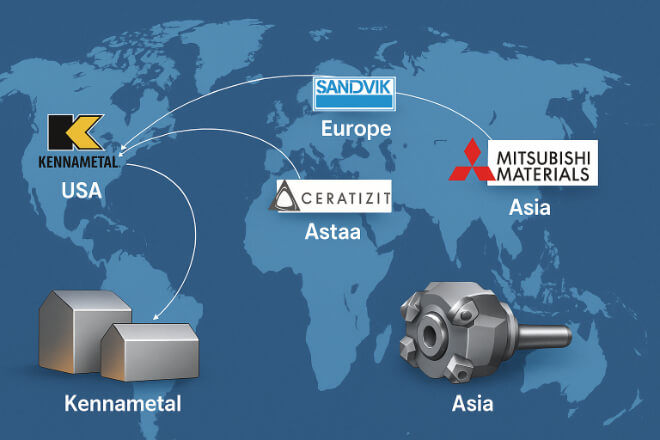

Leading Global Manufacturers

Several large companies dominate the global market:

Sandvik (Sweden) – Known for mining and construction tools.

Kennametal (USA) – Offers wide solutions in cutting and wear parts.

CERATIZIT (Luxembourg) – Strong in precision cutting and custom carbide.

Mitsubishi Materials (Japan) – Focused on advanced coatings and tooling.

Sumitomo Electric (Japan) – Large presence in cutting inserts and wear parts.

These companies set global benchmarks in technology, consistency, and performance.

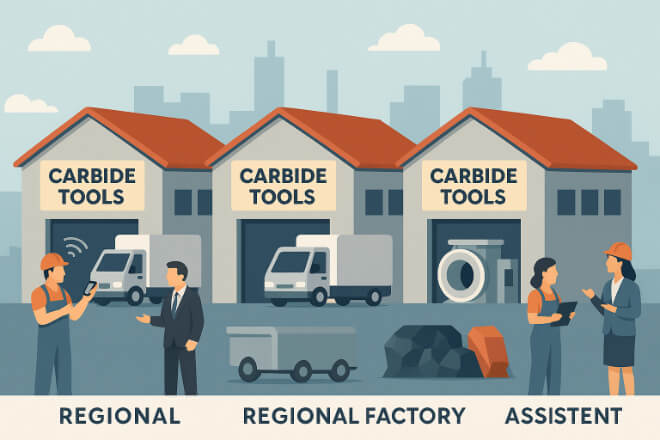

Regional and Local Specialists

Alongside global giants, many regional manufacturers serve local industries with shorter lead times and custom services. Examples include:

China and India – Strong in mass production and competitive pricing.

Europe – Specialized in high-end carbide for aerospace and automotive.

Southeast Asia – Suppliers for fast-growing electronics and textile industries.

For some buyers, a local supplier with technical support may be more valuable than a global giant.

Why Long-Term Partnerships Matter

Buying carbide wear parts is not just about a single purchase. Building a long-term relationship with the right manufacturer ensures:

Stable quality over years.

Better pricing agreements with volume.

Faster access to new technologies.

Priority support during urgent needs.

A trusted supplier becomes a partner in efficiency, not just a vendor.

خاتمة

Tungsten carbide wear parts are critical in industries where performance and reliability matter.

The manufacturer you choose plays a key role in ensuring these parts deliver value. By focusing on quality, technology, and service—not just cost—you can make smarter sourcing decisions.

For industries that run 24/7, the right carbide wear parts supplier is more than a choice—it’s an investment in long-term success.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.