يعد قطع الأسلاك مهمة شائعة في التصنيع والأعمال الكهربائية والبناء والعديد من الصناعات الأخرى.

في حين أن هناك العديد من أنواع قواطع الأسلاك في السوق، قواطع أسلاك كربيد التنغستن تتميز بقوتها ودقتها ومتانتها.

بالنسبة للشركات التي تحتاج إلى أداء قطع موثوق به لفترات طويلة، فإن هذه الأدوات تعد استثمارًا ذكيًا.

تشرح هذه المقالة ما هي قواطع الأسلاك المصنوعة من كربيد التنغستن، ولماذا هي أفضل من القواطع القياسية، وتطبيقاتها الصناعية، وكيفية اختيارها وصيانتها للحصول على أفضل النتائج.

ما هي قواطع الأسلاك المصنوعة من كربيد التنغستن؟

قواطع الأسلاك المصنوعة من كربيد التنغستن هي أدوات يدوية أو قواطع مثبتة على الآلة ولها حواف قطع معززة بكربيد التنغستن.

كربيد التنغستن مركب مصنوع من ذرات التنغستن والكربون، وهو معروف بصلابته الفائقة، إذ يأتي في المرتبة الثانية بعد الماس. صلابة يتيح للقواطع تقطيع المواد الصلبة مع قدر أقل من التآكل والتلف.

على عكس قواطع الفولاذ العادية، تحافظ قواطع الأسلاك المصنوعة من كربيد التنغستن على حدتها لفترة أطول بكثير، حتى في ظل الاستخدام الكثيف.

كما أنها تقاوم التقطيع والتشوه، مما يجعلها مثالية لقطع المواد التي قد تتسبب بسرعة في إتلاف الأدوات الأخرى.

لماذا يُعد كربيد التنغستن مثاليًا لقطع الأسلاك

إن خصائص كربيد التنغستن تجعله مثاليًا لقطع أنواع مختلفة من الأسلاك، وخاصة في البيئات الصناعية حيث تكون السرعة والدقة والمتانة مهمة.

المزايا الرئيسية

عالي صلابة - يمكنه قطع الأسلاك الصلبة دون أن يصبح باهتًا بسرعة.

مقاومة التآكل - يتعامل مع القطع المتكررة دون فقدان الكفاءة.

مقاومة للتآكل - تحافظ على الأداء حتى في البيئات الصعبة.

الدقة - تضمن قطعًا نظيفة ودقيقة للحصول على جودة أفضل للمنتج النهائي.

التطبيقات الصناعية لقواطع أسلاك كربيد التنغستن

تُستخدم قواطع أسلاك كربيد التنغستن في العديد من الصناعات. من بين التطبيقات الشائعة:

الكهربائية و الالكترونيات -قطع النحاس والألمنيوم والأسلاك الكهربائية الدقيقة.

البناء - تقليم أسلاك ربط قضبان التسليح والشبكة الفولاذية.

الفضاء الجوي - قطع السبائك المتخصصة المستخدمة في مكونات الطائرات.

السيارات - العمل مع كابلات الفرامل وأسلاك المحرك والأنابيب المعدنية.

التصنيع - تحضير الأسلاك لخطوط التجميع وعمليات الإنتاج.

أنواع قواطع أسلاك كربيد التنغستن

تصاميم مختلفة تناسب احتياجات مختلفة. إليك بعض الأنواع الرئيسية المستخدمة في البيئات الصناعية:

| يكتب | الاستخدام الرئيسي |

|---|---|

| قواطع قطرية | قطع الأسلاك للأغراض العامة |

| قواطع النهاية | قطع نهايات الأسلاك بحيث تكون متساوية مع الأسطح |

| قواطع ثقيلة | قطع الأسلاك السميكة والصلبة أو القضبان الصغيرة |

| قواطع دقيقة | للأعمال الإلكترونية والمجوهرات الفاخرة |

| قواطع مثبتة على الآلة | قطع الأسلاك الآلي في خطوط الإنتاج |

كيفية اختيار قواطع الأسلاك المناسبة من كربيد التنغستن

عند اختيار قواطع الأسلاك المصنوعة من كربيد التنغستن لشركتك، ضع العوامل التالية في الاعتبار:

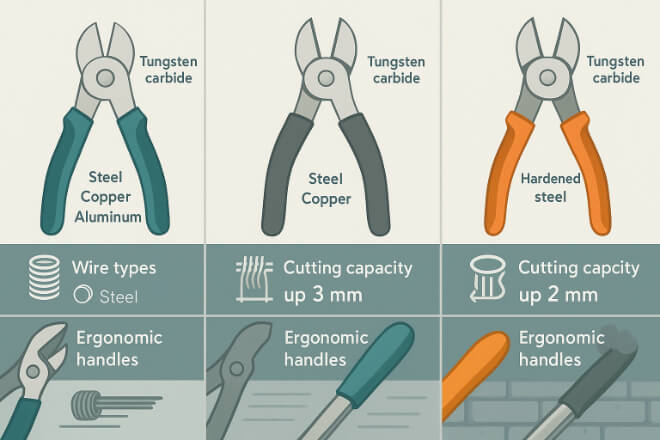

نوع السلك – اختر قاطعًا مصممًا وفقًا لصلابة وقطر السلك الذي تعمل به.

قدرة القطع - تأكد من أن الأداة قادرة على التعامل مع أكبر حجم من الأسلاك لديك.

تصميم المقبض - المقابض المريحة تقلل من تعب المشغل.

زاوية القطع - توفر الزوايا المختلفة مستويات مختلفة من الدقة.

سمعة العلامة التجارية - غالبًا ما توفر العلامات التجارية الراسخة جودة أفضل للمواد ودعمًا لما بعد البيع.

أفضل الممارسات لاستخدام قواطع الأسلاك المصنوعة من كربيد التنغستن

حتى أقوى القواطع تعمل بشكل أفضل وتدوم لفترة أطول عند استخدامها بشكل صحيح.

| أفضل الممارسات | لماذا هذا مهم |

|---|---|

| استخدم الأداة المناسبة للوظيفة | يمنع التحميل الزائد وتلف الشفرات |

| قطع عمودي على السلك | يقلل من الضغط ويضمن قطعًا نظيفة |

| تجنب الالتواء أثناء القطع | يمنع تقطيع حواف الكربيد |

| تنظيف بعد الاستخدام | يزيل الحطام الذي يمكن أن يسبب الصدأ أو البهتان |

| يحفظ في مكان جاف | يحمي من التآكل والتلف العرضي |

نصائح الصيانة لإطالة عمر الأداة

افحص بانتظام - ابحث عن الرقائق أو الشقوق في حواف القطع.

قم بالشحذ عند الحاجة - يمكن أن يؤدي إعادة الشحذ الاحترافي إلى إطالة عمر الأداة.

تجنب قطع المواد غير المناسبة - كربيد التنغستن قوي، لكنه ليس غير قابل للكسر.

قم بتزييت نقاط الارتكاز – مما يضمن التشغيل السلس ويقلل من التآكل.

قم بالتخزين بشكل صحيح - قم بتخزينه في علبة واقية عندما لا يكون قيد الاستخدام.

التكلفة مقابل القيمة في قواطع أسلاك كربيد التنغستن

عادةً ما تكون تكلفة قواطع أسلاك كربيد التنغستن أعلى من البدائل الفولاذية، لكنها تدوم لفترة أطول بكثير وتتطلب استبدالًا أقل. مع مرور الوقت، يُقلل هذا من تكاليف التشغيل ووقت التوقف عن العمل.

العوامل المؤثرة على السعر:

حجم الأداة وسعة القطع

درجة كربيد التنغستن

مقبض وتصميم مريح

العلامة التجارية والضمان

خاتمة

بالنسبة لصناع القرار في التصنيع أو البناء أو الإلكترونيات أو أي صناعة تعمل بالأسلاك، توفر قواطع الأسلاك المصنوعة من كربيد التنغستن أداءً ومتانة لا مثيل لها.

ورغم أن التكلفة الأولية قد تكون أعلى، فإن الفوائد طويلة الأجل في الكفاءة والجودة وتقليل استبدال الأدوات تجعلها استثمارًا قويًا.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.