Cryogenic and LNG (Liquefied Natural Gas) systems are designed to operate under extreme conditions.

These systems often involve very low temperatures, high pressures, and corrosive environments. To ensure these systems run efficiently and reliably, the right materials are essential.

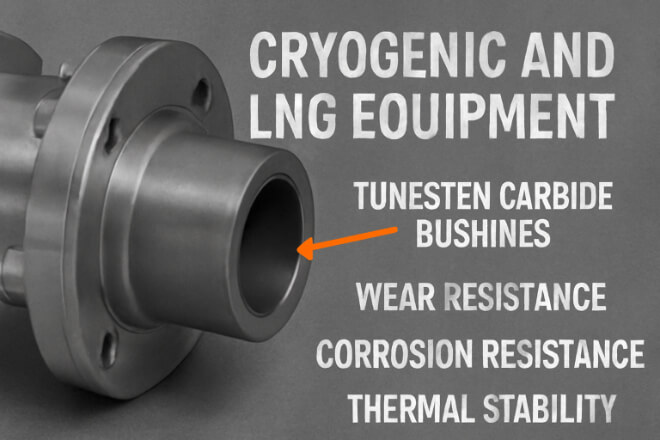

Tungsten carbide bushings are one such material that provides superior performance in cryogenic and LNG applications.

This article will explore why tungsten carbide bushings are ideal for these systems, their key benefits, and how to select the right material for your equipment.

Why Tungsten Carbide Bushings Are Ideal for Cryogenic and LNG Applications

Cryogenic and LNG equipment is exposed to harsh conditions, including freezing temperatures and corrosive substances.

Tungsten carbide bushings are perfect for these environments because of their outstanding properties:

عالي مقاومة التآكل: Tungsten carbide is extremely hard, making it resistant to the abrasive forces commonly found in cryogenic and LNG systems.

Cryogenic Stability: Unlike other materials that become brittle at low temperatures, tungsten carbide retains its toughness and performance even at cryogenic temperatures.

مقاومة التآكل: Tungsten carbide resists chemical and corrosive attacks, which is essential for LNG systems exposed to natural gas liquids and other aggressive substances.

Thermal Stability: Tungsten carbide can withstand both high and low temperatures, maintaining its mechanical properties across a broad temperature range, which is crucial for cryogenic systems that cycle between extreme temperatures.

These properties make tungsten carbide an excellent choice for cryogenic and LNG applications, where reliability, performance, and durability are critical.

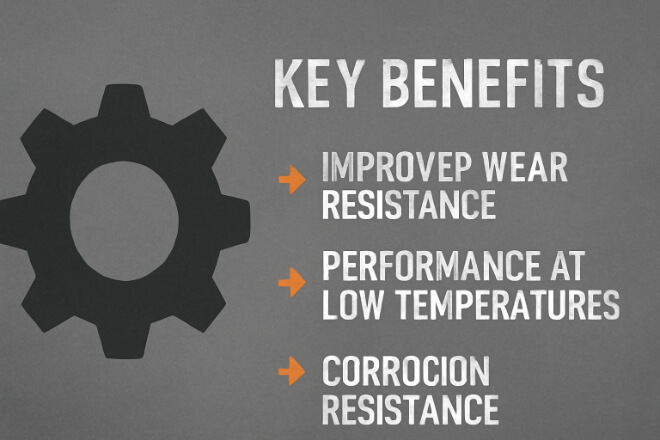

Key Benefits of Tungsten Carbide Bushings for Cryogenic and LNG Equipment

1). مقاومة التآكل

Cryogenic and LNG systems often deal with high friction and abrasive particles, especially in pumps, valves, and compressors.

Tungsten carbide’s hardness prevents wear, reducing the need for frequent replacements and lowering maintenance costs.

This makes it ideal for components that operate under constant wear conditions, like bushings in cryogenic pumps.

2). Reliable Performance at Low Temperatures

Cryogenic systems need materials that can withstand extreme cold without becoming brittle.

Tungsten carbide maintains its strength and durability at temperatures as low as -196°C (the temperature of liquid nitrogen).

This ensures that tungsten carbide bushings do not fail or degrade, even in the harshest cryogenic environments.

3). مقاومة التآكل

LNG and cryogenic systems are often exposed to corrosive gases, liquids, and chemicals.

Tungsten carbide’s resistance to corrosion ensures long-lasting performance even in environments where other materials would corrode or degrade.

This is especially important for LNG systems that handle natural gas liquids, which can be highly corrosive.

4). Thermal Cycling Stability

Cryogenic and LNG equipment often undergo rapid temperature fluctuations as they cycle between the cold storage of liquefied gas and its vaporization.

Tungsten carbide’s thermal stability ensures that it can withstand these temperature changes without losing its mechanical integrity, preventing failures in critical system components.

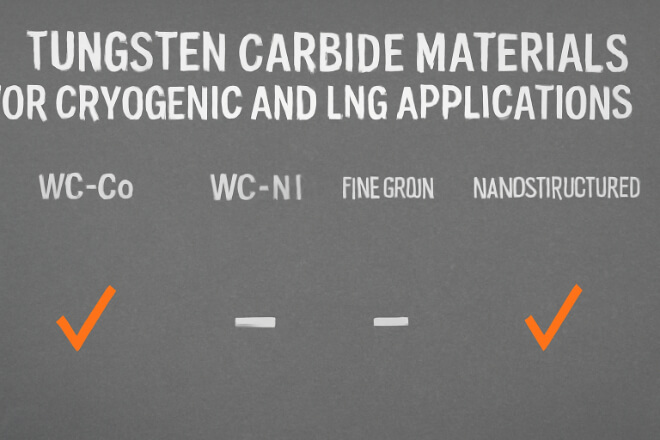

Types of Tungsten Carbide Materials for Cryogenic and LNG Equipment

The selection of tungsten carbide material depends on the specific requirements of the cryogenic or LNG system.

The key factors to consider include binder material, grain size, and the environment in which the bushing will be used. The most commonly used tungsten carbide types in these applications are:

1). WC-Co (Cobalt Binder Tungsten Carbide)

WC-Co is the most common tungsten carbide material, known for its high مقاومة التآكل and toughness.

The cobalt binder enhances the material’s toughness, making it suitable for high-impact and high-stress applications like cryogenic pumps and valves.

Best for: Abrasive slurry handling, high-impact cryogenic pumps, and valves.

2). WC-Ni (Nickel Binder Tungsten Carbide)

WC-Ni uses nickel instead of cobalt as a binder. This formulation offers superior مقاومة التآكل, making it ideal for LNG systems that deal with corrosive substances, such as natural gas liquids.

Best for: Cryogenic and LNG equipment exposed to aggressive chemicals or corrosive fluids.

3). Fine-Grain Tungsten Carbide

Fine-grain tungsten carbide is produced by reducing the grain size of tungsten carbide particles.

This results in a denser, harder material that provides better wear resistance and a smoother surface finish.

Fine-grain tungsten carbide is ideal for systems with smaller, abrasive particles or where precision is required.

Best for: High-abrasion environments like cryogenic pumps and LNG compressors.

4). Nanostructured Tungsten Carbide

Nanostructured tungsten carbide combines ultra-fine grain sizes with advanced manufacturing techniques, improving both wear resistance and صلابة.

It performs well in systems requiring both hardness and high impact resistance.

- Best for: High-performance LNG and cryogenic systems requiring superior wear resistance and toughness.

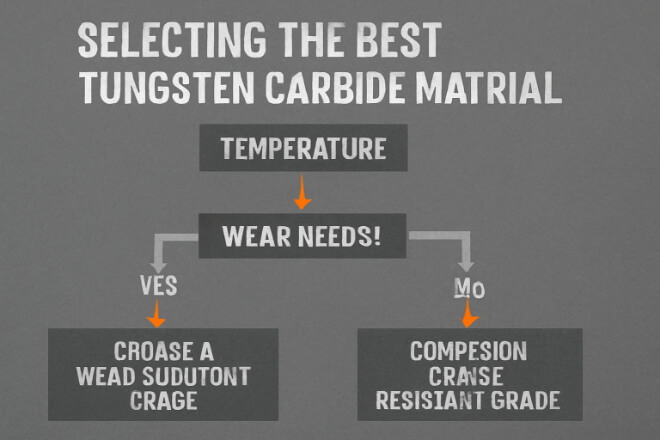

Key Considerations When Choosing Tungsten Carbide Bushings for Cryogenic and LNG Equipment

Choosing the right material for tungsten carbide bushings in cryogenic and LNG equipment depends on several factors:

1). Temperature Range

The material should be able to maintain its properties at the operating temperature of the system.

For cryogenic applications, tungsten carbide with fine-grain or nanostructured compositions may be the best choice due to their high performance at low temperatures.

2). Corrosive Environments

If the equipment is exposed to corrosive gases or liquids, WC-Ni offers excellent corrosion resistance.

This makes it ideal for LNG applications, where the risk of corrosion is high due to natural gas liquids and chemicals.

3). Wear vs. Impact Resistance

In systems where مقاومة التآكل is critical, fine-grain tungsten carbide provides enhanced hardness and durability.

However, if the application also involves high-impact forces, WC-Co or nanostructured tungsten carbide might be better options due to their toughness.

4). Cost vs. Performance

While materials like WC-Co and nanostructured tungsten carbide offer superior performance, they may come at a higher cost.

It’s essential to balance performance with the specific needs of your equipment and system requirements.

Applications of Tungsten Carbide Bushings in Cryogenic and LNG Equipment

Tungsten carbide bushings are used in several critical components in cryogenic and LNG systems, including:

Cryogenic Pumps: Tungsten carbide bushings are essential in pumps that handle liquefied gases, where reliability and wear resistance are critical.

Cryogenic Valves: Tungsten carbide is used in valve components, ensuring precise operation and durability at low temperatures.

Cryogenic Tanks: Tungsten carbide bushings help in maintaining the seals and integrity of storage tanks, preventing wear and ensuring long service life.

LNG Transport Equipment: Tungsten carbide is used in LNG transport pipelines and valves to withstand the extreme pressures and temperatures encountered during transportation.

خاتمة

Tungsten carbide bushings are indispensable in cryogenic and LNG applications due to their exceptional wear resistance, corrosion resistance, and thermal stability.

By selecting the right material—whether it’s WC-Co, WC-Ni, fine-grain tungsten carbide, or nanostructured tungsten carbide—industries can ensure reliable and efficient performance in cryogenic and LNG systems, improving the longevity and safety of their equipment.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.