في الصناعات التي تتعامل فيها الآلات مع الضغط العالي أو السرعة العالية أو السوائل المسببة للتآكل، يجب أن تكون أنظمة الختم قوية وموثوقة.

قد يؤدي ضعف الختم إلى تسربات أو توقف مؤقت أو حتى حوادث. أحد أفضل الحلول هو حلقة ختم من كربيد التنغستن.

كربيد التنغستن معروف بـ صلابة والمتانة. عند استخدامه في حلقات الختم، يوفر حماية ممتازة ضد التآكل والحرارة والمواد الكيميائية.

بالنسبة لصناع القرار، فإن فهم ماهية هذه الحلقات وكيفية عملها هو أمر أساسي لإجراء استثمارات ذكية.

يشرح هذا الدليل كل ما تحتاج إلى معرفته حول حلقات ختم كربيد التنغستن - خصائصها وفوائدها وتطبيقاتها وكيفية اختيار النوع المناسب.

ما هي حلقات ختم كربيد التنغستن؟

حلقات ختم كربيد التنغستن هي مكونات ختم ميكانيكية مصنوعة من مركبات التنغستن والكربون.

يتم إضافة كمية صغيرة من المادة الرابطة (الكوبالت أو النيكل) لتحسين صلابة.

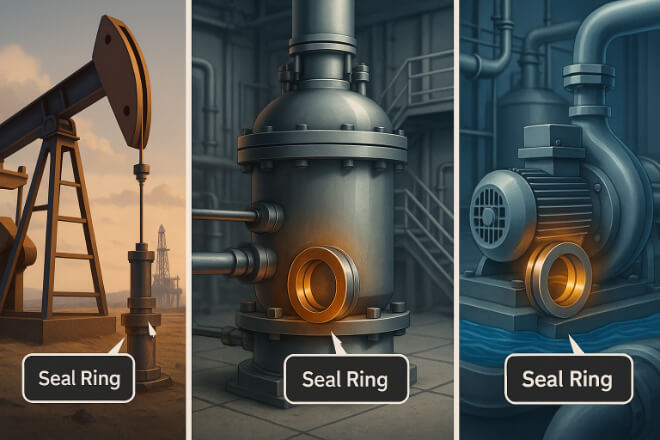

تُستخدم هذه الحلقات في المضخات، والضواغط، والخلاطات، وغيرها من الآلات الدوارة.

غرضها الرئيسي هو منع تسرب السوائل أو الغازات مع تحمل الاحتكاك والضغط.

المميزات الرئيسية:

أقصى صلابة (قريب من الماس)

مقاومة التآكل والصدأ

عمر خدمة طويل في ظل الظروف الصعبة

أداء مستقر في درجات الحرارة العالية

لماذا تختار كربيد التنغستن لحلقات الختم؟

يمكن تصنيع حلقات الختم من السيراميك، أو كربيد السيليكون، أو الفولاذ المقاوم للصدأ. ومع ذلك، يتميز كربيد التنغستن لعدة أسباب:

صلابة فائقة: تتعامل مع السوائل الكاشطة بشكل أفضل من معظم المواد.

كثافة عالية: توفر قدرة قوية على الختم تحت الأحمال الثقيلة.

الاستقرار الحراري: يعمل في البيئات الساخنة والباردة.

متعددة الاستخدامات: مناسبة لإغلاق الزيوت والمياه والمواد الكيميائية وحتى الغاز.

عمر أطول: يقلل من وقت التوقف وتكاليف الاستبدال.

بالنسبة للصناعات التي تعتبر فيها الموثوقية أمرًا مهمًا، فإن حلقات ختم كربيد التنغستن غالبًا ما تكون الخيار الأكثر فعالية من حيث التكلفة.

فوائد حلقات ختم كربيد التنغستن

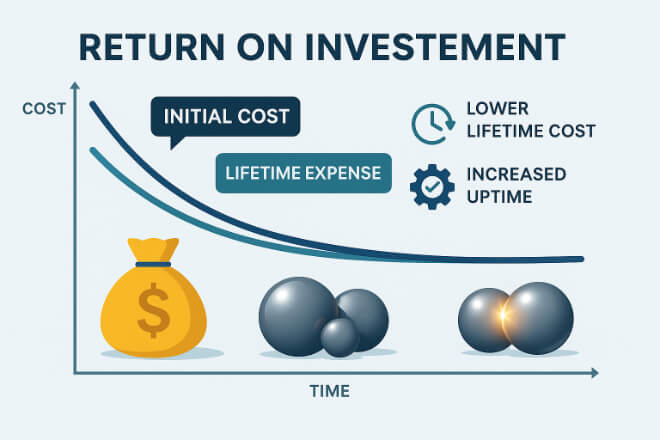

1) عمر خدمة أطول

يمكن أن تدوم 5 إلى 10 مرات أطول من الحلقات الفولاذية العادية، مما يوفر المال على المدى الطويل.

2) ممتاز مقاومة التآكل

حتى في السوائل الكاشطة مثل الملاط أو المخاليط الكيميائية، فإنها تقاوم الخدش والتآكل.

3) حماية أفضل من التآكل

تتمتع حلقات كربيد التنغستن المرتبطة بالنيكل بمقاومة خاصة للأحماض ومياه البحر.

4) أداء عالي في الختم

يحافظون على الإغلاق المحكم حتى عند الضغط العالي، مما يقلل من خطر التسرب.

5) توفير التكاليف

على الرغم من أن التكلفة الأولية أعلى، فإن عدد عمليات الاستبدال الأقل ووقت التوقف الأقل يعني عائد استثمار أقوى.

أنواع حلقات ختم كربيد التنغستن

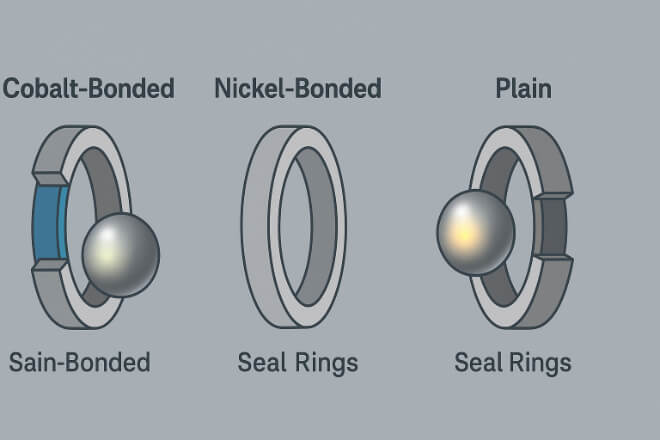

1). حلقات مرتبطة بالكوبالت

مزيد من المتانة

مثالي ل النفط والغاز صناعة

أقل قليلا مقاومة التآكل

2). حلقات ملتصقة بالنيكل

أفضل ضد الأحماض ومياه البحر

شائع في التطبيقات الكيميائية والبحرية

3). حلقات الختم العادية

الختم الأساسي للمياه والآلات العامة

4). حلقات الختم المركبة

كربيد التنغستن الممزوج بالسيراميك أو كربيد السيليكون

يتم استخدامه عندما تتطلب الظروف القاسية حماية متعددة الطبقات

التطبيقات الشائعة

النفط والغاز صناعة

يستخدم في المضخات والضواغط حيث يكون الضغط مرتفعًا والسوائل كاشطة.

الصناعة الكيميائية

يحمي الأنظمة من التآكل الناتج عن الأحماض والمواد الكيميائية العدوانية.

البحرية والبرية

يتعامل مع التعرض لمياه البحر ويمنع التسرب في المضخات تحت الماء.

محطات الطاقة

يضمن بقاء التوربينات والمضخات خالية من التسرب تحت الضغط الشديد.

الأغذية والأدوية

يحافظ على الخلاطات والمضخات خالية من التسرب مع تلبية معايير النظافة.

كيفية اختيار حلقة ختم كربيد التنغستن المناسبة

عند اتخاذ قرار الشراء، ضع في اعتبارك ما يلي:

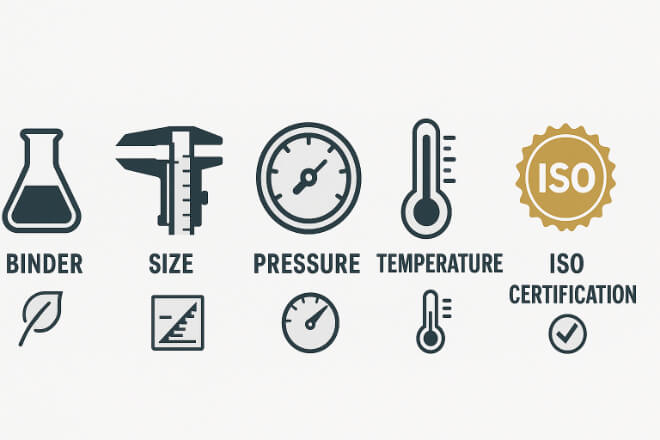

1) مادة الرابط:

الكوبالت ل صلابة

النيكل ل مقاومة التآكل

2) الحجم والشكل:

يجب أن يتناسب مع تصميم المضخة أو الضاغط.

3) ظروف التشغيل:

نطاق درجة الحرارة

مستوى الضغط

نوع السائل أو الغاز

4) خيارات الطلاء:

يتم طلاء بعض الحلقات بطبقات خاصة لتقليل الاحتكاك.

5) شهادة المورد:

تضمن معايير الجودة ISO أو غيرها من المعايير الموثوقية.

أفضل الممارسات لاستخدام حلقات الختم

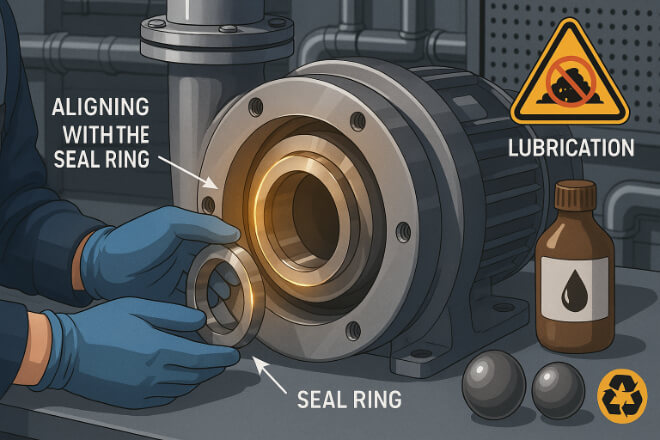

التثبيت الصحيح: يؤدي عدم المحاذاة إلى تقليل عمر المنتج.

التزييت المناسب: ضروري لتقليل الاحتكاك والحرارة.

التفتيش المنتظم: ابحث عن الشقوق أو الخدوش أو التآكل غير المتساوي.

تجنب التلوث: يمكن للأوساخ أو الرمال أن تتسبب في إتلاف الحلقة بسرعة.

الاستبدال في الوقت المناسب: لا تنتظر الفشل الكامل؛ خطط للاستبدال الوقائي.

الصيانة والاستبدال

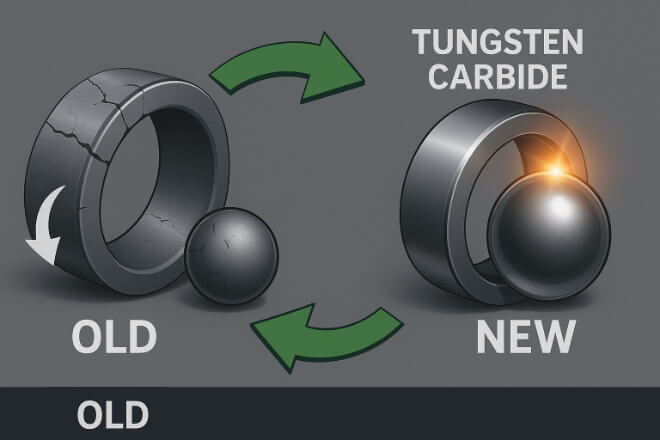

حتى أقوى حلقات الختم تتآكل في نهاية المطاف.

تردد التفتيش: كل 2-4 أسابيع في العمليات الحرجة.

علامات التآكل: زيادة التسرب أو الضوضاء أو الاهتزاز.

سياسة الاستبدال: قم دائمًا بالاستبدال بنفس الدرجة والأبعاد.

إعادة التدوير: يمكن إعادة تدوير حلقات كربيد التنغستن المستهلكة، مما يؤدي إلى خفض التكاليف.

فوائد التكلفة للشركات

تكلفة صيانة أقل: الحاجة إلى استبدالات أقل.

تقليل وقت التوقف عن العمل: تظل الآلات قيد التشغيل لفترة أطول.

عمليات أكثر أمانًا: تعمل الأختام الأقوى على تقليل مخاطر الحوادث.

عائد استثمار أعلى: المدخرات بمرور الوقت تفوق السعر الأعلى المقدم.

بالنسبة لصناع القرار، فإن الميزة المالية واضحة: فانخفاض عدد الإخفاقات يعني زيادة الإنتاجية وربحية أقوى.

دراسات الحالة

1) شركة حفر النفط

بعد التحول إلى حلقات ختم كربيد التنغستن، نجحت الشركة في تقليل وقت التوقف عن العمل بمقدار 40% لأن الأختام استمرت لفترة أطول في سوائل الحفر الكاشطة.

2) مصنع كيميائي

تتمتع الحلقات المرتبطة بالنيكل بمقاومة للتآكل الحمضي، مما يؤدي إلى خفض تكرار الاستبدال إلى النصف.

3). مصنع المضخات البحرية

تتمتع حلقات الختم بقدرة تحمل أطول في ظروف مياه البحر، مما أدى إلى تحسين رضا العملاء وخفض مطالبات الضمان.

كيفية الحصول على حلقات ختم كربيد التنغستن

عند تحديد المصادر، ينبغي لصناع القرار أن يقوموا بما يلي:

اختيار الموردين ذوي الخبرة المثبتة في الصناعة

تأكيد شهادات الجودة و ISO

اسأل عن المخزون المحلي للحصول على تسليم أسرع

اطلب تصميمات مخصصة إذا كنت بحاجة إلى أحجام فريدة

تحقق من خدمة ما بعد البيع للدعم الفني

لمزيد من المعلومات حول الموردين، قم بزيارة ريتوبز.كوم لاستكشاف الخيارات العالمية الموثوقة.

خاتمة

حلقات مانعة للتسرب من كربيد التنغستن هي أساس أنظمة الختم الموثوقة. صلابتها، ومقاومتها للتآكل، وحمايتها من التآكل تجعلها الخيار الأمثل للصناعات المتطلبة.

بالنسبة لقادة الشركة، فإن اختيار كربيد التنغستن يعني أداءً أقوى وعمر خدمة أطول وتكاليف إجمالية أقل.

سواء في الصناعات النفطية والغازية أو الكيميائية أو البحرية أو الطاقة، توفر هذه الحلقات الأمن والكفاءة التي تحتاجها الشركات.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.