In today’s industrial world, decision-makers face not only performance and cost challenges but also environmental responsibility. Many industries—from mining and oil & gas to metal forming and woodworking—depend on tungsten carbide wear parts.

These parts are known for their hardness, long life, and wear resistance. But one important question is becoming more common: Are tungsten carbide wear parts environmentally friendly?

This article looks at the environmental side of tungsten carbide. We will explore its production, use, recycling, and how industries can balance performance with sustainability.

What Makes Tungsten Carbide Special?

Tungsten carbide is a material made by combining tungsten and carbon.

When mixed with a binder metal, usually cobalt, it forms one of the hardest and most durable materials used in modern industry.

Key properties include:

High hardness and wear resistance

Longer service life compared to steel

Resistance to high temperatures

Ability to perform in extreme conditions

These advantages reduce downtime and replacement frequency, which already adds an environmental benefit by lowering waste.

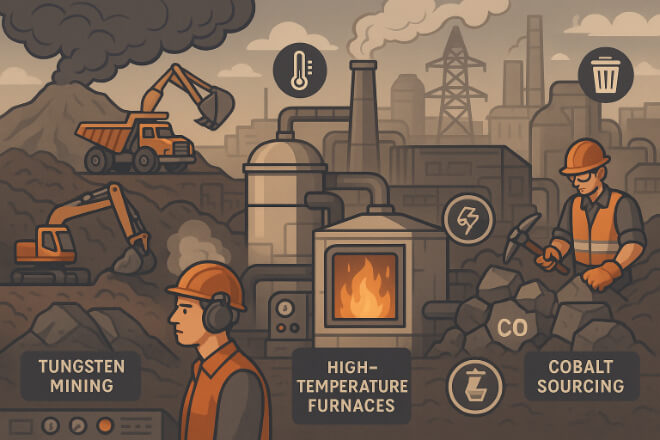

Environmental Challenges in Production

Like any industrial material, tungsten carbide has environmental costs during production.

1). Mining of Tungsten

Tungsten is mainly mined in China, Russia, and some European countries.

Mining activities can disturb local ecosystems, use significant energy, and generate waste.

2). Energy Use in Processing

Tungsten carbide is made through powder metallurgy, requiring high-temperature furnaces for sintering.

This process consumes large amounts of energy and may contribute to carbon emissions.

3). Use of Cobalt

Cobalt, often used as a binder, has environmental and ethical concerns due to its mining practices.

Responsible sourcing is becoming an important issue for decision-makers.

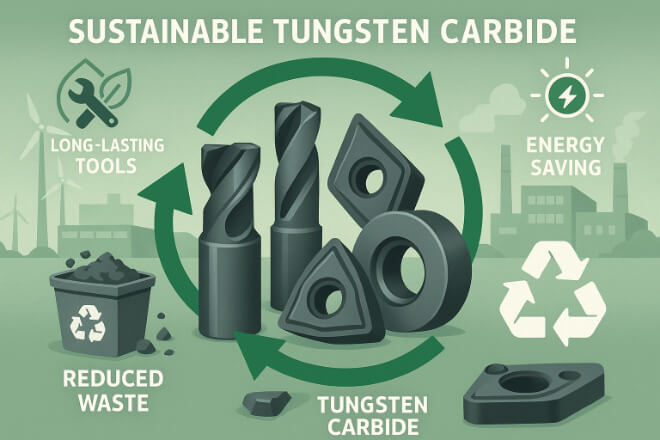

Positive Environmental Aspects of Tungsten Carbide

Even though its production has challenges, tungsten carbide also offers eco-friendly benefits:

Durability and Long Life

Tungsten carbide wear parts last 3–10 times longer than steel. This reduces the number of replacements, saving materials and energy in the long run.

Reduced Waste

Since parts last longer, industries generate less scrap metal and industrial waste.

Energy Efficiency in Use

In machining or drilling, sharper and harder tungsten carbide tools need less energy to perform the same job.

Recyclability

Tungsten carbide can be collected, reprocessed, and reused, making it part of a circular economy.

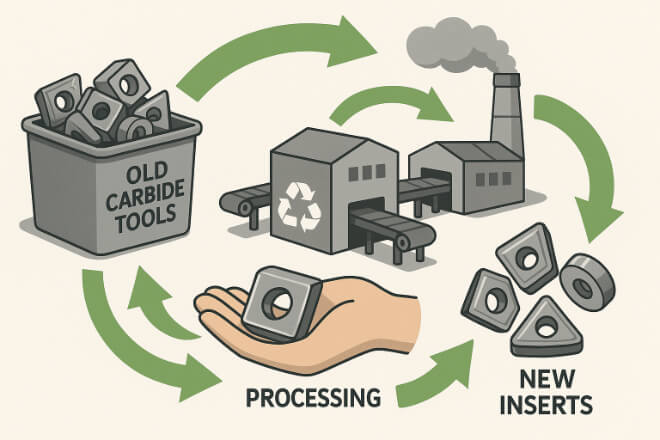

Recycling of Tungsten Carbide

One of the strongest environmental advantages of tungsten carbide is its recycling potential.

Scrap Collection: Old tools, inserts, and wear parts can be gathered instead of sent to landfills.

Chemical Recycling: Processes like the zinc method or chemical extraction allow tungsten carbide to be reused without losing quality.

Energy Savings: Recycling tungsten carbide requires much less energy compared to mining and processing new tungsten.

Cost Efficiency: Companies can save money by reusing scrap material while reducing their environmental footprint.

For decision-makers, investing in a recycling program or working with suppliers that recycle tungsten carbide is both sustainable and cost-effective.

How Do Tungsten Carbide Parts Compare Environmentally to Other Materials?

Here is a comparison between tungsten carbide and common alternatives:

| Material | Durability | Recyclability | Environmental Impact |

|---|---|---|---|

| Tungsten Carbide | Very High (long life) | High (recyclable with proper methods) | Moderate (energy use in production, but offset by long life) |

| Steel | Medium (shorter life) | Very High (easily recycled) | High (frequent replacements create more waste) |

| Ceramics | High (but brittle) | Low (difficult to recycle) | Moderate (shorter life if broken) |

| Plastics/Polymers | Low | Low (not widely recycled) | High (high waste and pollution risk) |

Strategies for Improving Environmental Performance

For companies using tungsten carbide wear parts, there are clear strategies to make operations more sustainable:

1). Work with Responsible Suppliers

Choose suppliers that use certified and ethically sourced tungsten and cobalt.

2). Implement Recycling Programs

Collect worn tungsten carbide tools and send them to recycling facilities.

3). Use Coatings to Extend Life

Applying protective coatings can make tungsten carbide last even longer, reducing replacements.

4). Adopt Additive Manufacturing

New methods like 3D printing tungsten carbide allow for efficient designs with less waste.

5). Regular Maintenance

Ensuring proper lubrication, cooling, and handling extends tool life and reduces premature disposal.

The Bigger Picture: Sustainability and Decision-Making

For executives and operations leaders, the key challenge is balancing performance, cost, and sustainability.

Tungsten carbide wear parts, when used responsibly, can be part of a sustainable business model.

Lower waste and longer life cycles reduce environmental impact.

Recycling options make it possible to re-enter tungsten into the supply chain.

Supplier responsibility helps avoid ethical and ecological issues in mining.

Making sustainability part of procurement and production decisions is not only good for the environment but also strengthens a company’s reputation and competitiveness.

Conclusion

So, are tungsten carbide wear parts environmentally friendly? The answer is yes—with conditions.

While production and raw material mining can have environmental costs, the durability, efficiency, and recyclability of tungsten carbide make it much greener than many alternatives.

For decision-makers, the takeaway is clear:

Invest in long-life tungsten carbide wear parts.

Build or join recycling programs.

Work with responsible suppliers.

Explore coatings and new manufacturing methods for added sustainability.

By doing so, companies can enjoy the high performance of tungsten carbide while also meeting environmental goals.

If you want to know more details about any company, please feel free to contact us.