Marine and offshore operations are some of the toughest industrial environments.

Equipment such as pumps, compressors, propulsion systems, and drilling platforms must operate continuously while exposed to seawater, pressure, vibration, and corrosive fluids.

In such settings, sealing systems play a critical role in preventing leaks and protecting machinery.

Among the many materials available, tungsten carbide seal rings have proven to be one of the most reliable choices.

This article explains their benefits, performance advantages, and why decision-makers in the marine and offshore sectors should consider them for long-term efficiency and safety.

Why Sealing Is Critical Offshore

Marine and offshore systems work in harsh environments where failure can be costly and dangerous. Seal rings ensure:

Leak prevention – Protecting motors, bearings, and sensitive components.

Corrosion resistance – Withstanding constant exposure to seawater.

Safety – Preventing spills of oil, gas, or chemicals.

Operational reliability – Keeping pumps and compressors running around the clock.

If seals fail offshore, repairs are expensive and downtime can lead to lost production and safety risks.

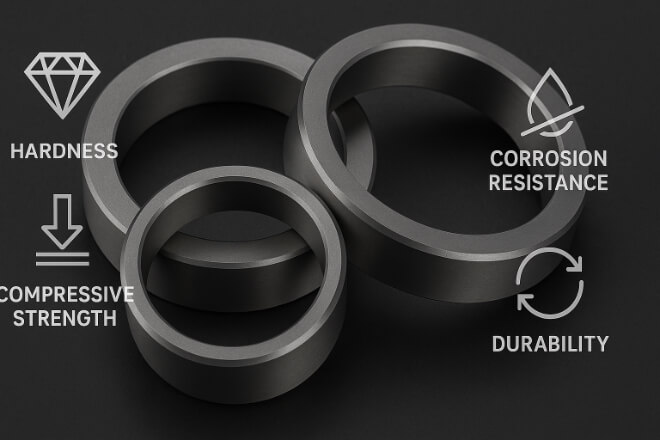

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is made from tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for offshore sealing:

High hardness – Resists wear from friction and abrasive seawater particles.

Compressive strength – Withstands heavy loads and pump pressure.

Corrosion resistance – Nickel-bonded tungsten carbide is especially effective in seawater.

Thermal stability – Works reliably in both hot and cold marine conditions.

Durability – Long service life reduces maintenance needs.

Benefits in Marine and Offshore Operations

1). Resistance to Seawater Corrosion

Seawater is highly corrosive to metals. Nickel-bonded tungsten carbide seal rings provide excellent protection, extending equipment life.

2). Better Performance Under Pressure and Shock

Offshore pumps and drilling equipment face constant vibration and sudden pressure changes.

Tungsten carbide seal rings handle these stresses better than ceramic or steel alternatives.

3). Longer Service Life

Their wear resistance means fewer replacements and lower maintenance costs, which is especially valuable where offshore access is limited.

4). Increased Equipment Reliability

Reliable seals mean fewer breakdowns, less downtime, and more efficient operations. This directly translates into cost savings.

5). Sustainability Advantage

Tungsten carbide rings can be recycled, reducing waste and supporting environmental goals in offshore industries.

Cobalt-Bonded vs Nickel-Bonded Grades

1). Cobalt-bonded tungsten carbide

Higher toughness, ideal for shock and vibration.

Best suited for oil drilling and offshore mining systems.

2). Nickel-bonded tungsten carbide

Superior corrosion resistance.

Best for seawater pumps, marine propulsion, and offshore chemical applications.

The choice depends on whether the primary challenge is corrosion or mechanical shock.

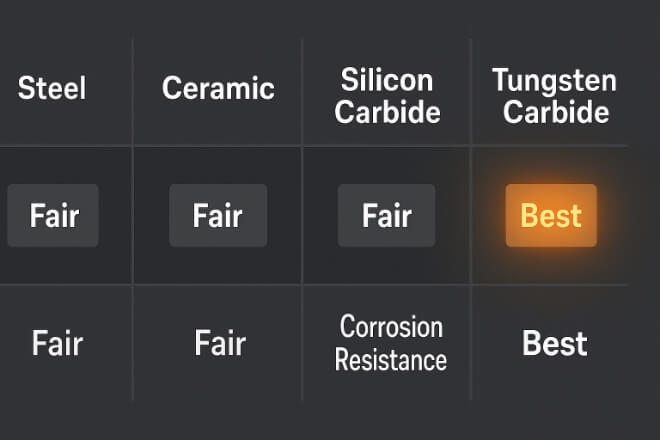

Comparison with Other Seal Materials

Steel seals – Corrode quickly in seawater.

Ceramic seals – Resist corrosion but are brittle under shock.

Silicon carbide seals – Good chemical resistance, but less tough under vibration.

Tungsten carbide seals – Offer the best overall balance of toughness, durability, and corrosion resistance.

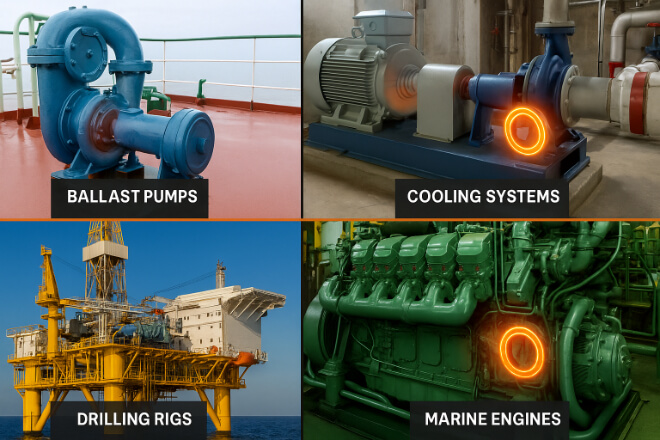

Applications in Marine and Offshore Systems

Ballast pumps – Handle large volumes of seawater safely.

Cooling pumps – Ensure engines and systems remain stable.

Propulsion systems – Provide reliability for ships and offshore platforms.

Drilling pumps – Resist wear from abrasive fluids and pressure cycles.

Offshore chemical systems – Protect against aggressive solvents and fluids.

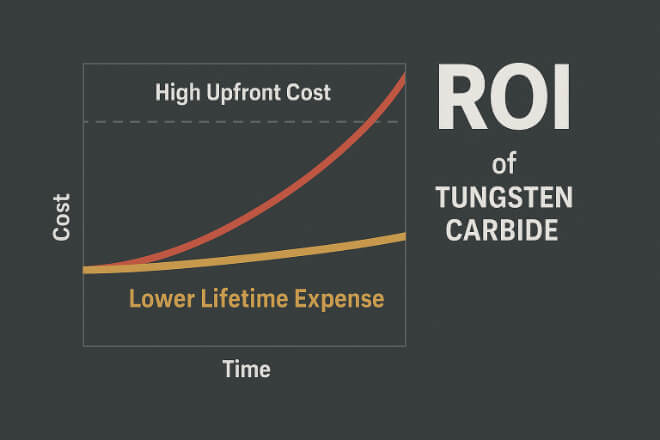

Cost vs Long-Term Value

While tungsten carbide seal rings cost more upfront, their long-term value is clear:

Lower maintenance costs → Fewer repairs and replacements.

Less downtime → Higher production efficiency.

Extended equipment life → Protects critical offshore machinery.

Better ROI → Savings outweigh the higher purchase price.

Best Practices for Offshore Use

To maximize benefits in marine and offshore operations:

Select the right binder → Nickel for seawater, cobalt for vibration.

Use proper installation techniques → Prevent scratches or misalignment.

Schedule regular inspections → Identify wear before failure occurs.

Ensure correct lubrication → Reduce friction and extend seal life.

Key Takeaways for Decision-Makers

Tungsten carbide seal rings provide unmatched durability in marine and offshore systems.

They resist corrosion, wear, and mechanical stress better than alternatives.

Nickel-bonded grades are ideal for seawater, while cobalt-bonded grades are best for high-shock applications.

Higher upfront cost results in long-term savings and improved safety.

Recycling adds a sustainability benefit for offshore operations.

Conclusion

For marine and offshore operations where equipment faces constant exposure to seawater, vibration, and pressure, tungsten carbide seal rings are essential. They deliver reliability, reduce downtime, and ensure long-term performance.

For decision-makers, investing in tungsten carbide seal rings is more than a technical choice—it is a strategic step toward safer, more efficient, and more sustainable offshore operations.

If you want to know more details about any company, please feel free to contact us.