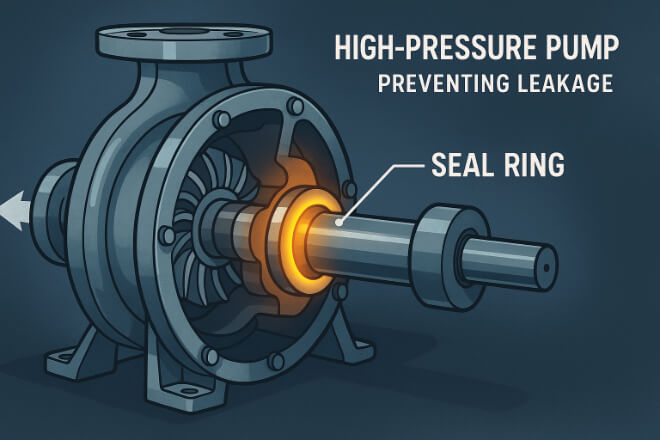

High-pressure pumps are vital in industries such as oil and gas, power generation, chemical plants, and marine systems. These pumps must operate under extreme pressure and sometimes corrosive conditions.

The seal ring is one of the most important parts of these pumps because it prevents leakage, protects equipment, and ensures safety.

When choosing the right seal ring, tungsten carbide stands out as one of the best materials.

This article explores why tungsten carbide seal rings are ideal for high-pressure pumps, the different grades available, and what decision-makers should consider when selecting them.

Why High-Pressure Pumps Need Strong Seal Rings

High-pressure pumps face conditions that can destroy weak seals:

Extreme pressure causes deformation in softer materials.

Friction and wear damage sealing surfaces.

Heat buildup stresses materials.

Corrosive fluids weaken seals over time.

If seals fail, the pump stops working, leading to downtime and expensive repairs.

Tungsten carbide seal rings resist these challenges better than most other materials.

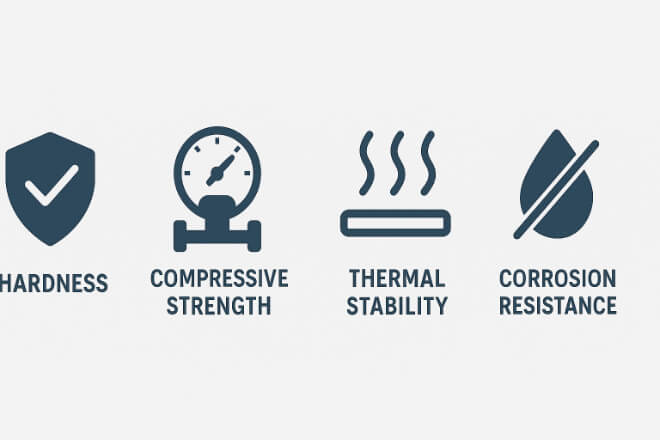

Key Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a hard material made by combining tungsten and carbon with a binder such as cobalt or nickel. Its properties include:

Extreme hardness → Resists wear from friction and particles.

High compressive strength → Withstands heavy pressure without breaking.

Thermal stability → Maintains strength under high operating temperatures.

Corrosion resistance → Protects against chemicals, oil, and seawater.

Dimensional stability → Keeps precise shape for tight sealing.

These features make tungsten carbide seal rings the best option for high-pressure pumps.

Grades of Tungsten Carbide for Seal Rings

Different grades of tungsten carbide are used depending on pump conditions:

1). Cobalt-Bonded Tungsten Carbide

Offers higher toughness.

Best for pumps exposed to mechanical shock or vibration.

Slightly less resistant to corrosion.

2). Nickel-Bonded Tungsten Carbide

Provides better resistance to chemicals and seawater.

Best for marine pumps or chemical plant pumps.

Slightly lower toughness than cobalt-bonded.

Choosing the right grade ensures maximum life and efficiency.

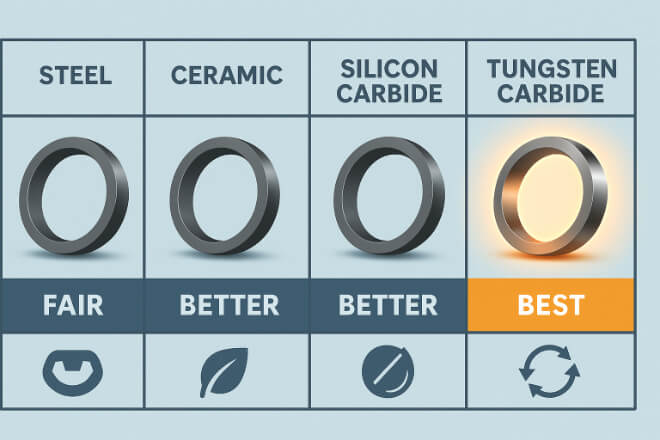

Advantages Over Other Materials

When compared with steel, ceramics, and silicon carbide, tungsten carbide offers a better balance of properties:

Steel seals – Strong but corrode quickly in harsh environments.

Ceramic seals – Resist corrosion but break under impact.

Silicon carbide seals – Good in chemicals but more brittle under shock.

Tungsten carbide seals – Provide durability, toughness, and versatility across multiple industries.

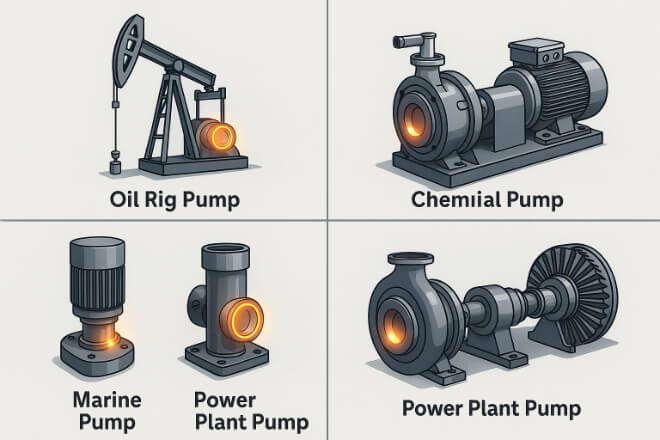

Applications of Tungsten Carbide Seal Rings in High-Pressure Pumps

Tungsten carbide seal rings are widely used in:

Oil and gas pumps → Handling high-pressure crude and gas.

Power plant cooling pumps → Operating under constant stress and heat.

Marine pumps → Ballast and circulation systems exposed to seawater.

Chemical process pumps → Handling corrosive fluids and high pressure.

Across all these sectors, tungsten carbide is valued for long-term reliability.

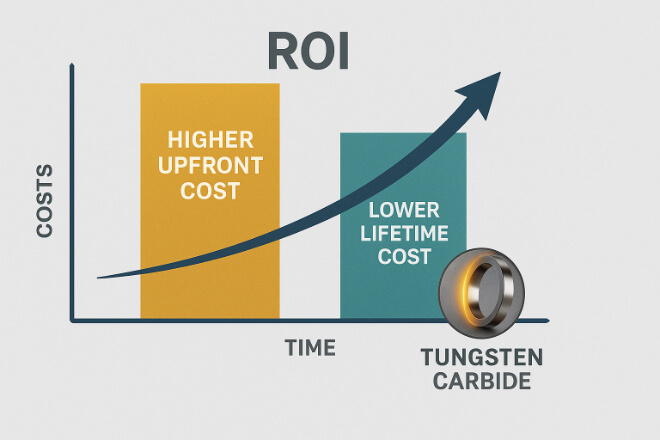

Cost vs Long-Term Value

Although tungsten carbide seal rings are more expensive at purchase, their durability reduces:

Replacement frequency

Downtime costs

Inventory needs

Maintenance labor

Over the full life cycle, tungsten carbide rings deliver better ROI than cheaper alternatives.

Best Practices for Extending Service Life

To get the most from tungsten carbide seal rings in high-pressure pumps:

Install carefully to avoid damage.

Inspect regularly for cracks or wear.

Use correct lubrication to minimize friction.

Choose the right grade based on pump environment.

Following these practices ensures maximum performance and long service life.

Sustainability Benefits

Tungsten carbide is also recyclable. Worn seal rings can be collected, processed, and reused to make new products. This reduces waste and supports sustainable industrial practices.

Key Takeaways for Decision-Makers

Best material for high-pressure pumps due to strength, wear resistance, and durability.

Two main grades: cobalt-bonded (toughness) and nickel-bonded (corrosion resistance).

Long-term ROI from reduced downtime and fewer replacements.

Sustainability advantage through recyclability.

For industries where pumps must run reliably under pressure, tungsten carbide seal rings are the best choice.

Conclusion

Tungsten carbide seal rings are the most reliable option for high-pressure pumps. They combine hardness, toughness, and chemical resistance to deliver long-term performance.

For decision-makers in oil and gas, marine, power, and chemical industries, investing in tungsten carbide is not just a technical choice—it is a strategic decision for efficiency, safety, and sustainability.

If you want to know more details about any company, please feel free to contact us.