In the world of advanced materials, binder material is one of the most critical components in the production of tungsten carbide (WC) tools. Although tungsten carbide itself is known for its exceptional hardness and wear resistance, it is the binder material that gives these tools their toughness, durability, and structural integrity. This article explores what binder material is, how it functions, and why it is essential in cemented carbide tools.

What Is Binder Material?

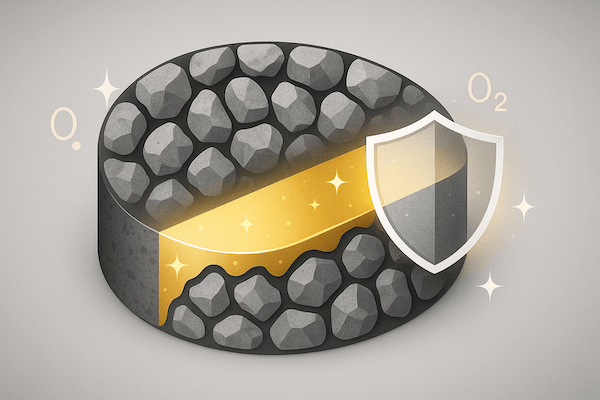

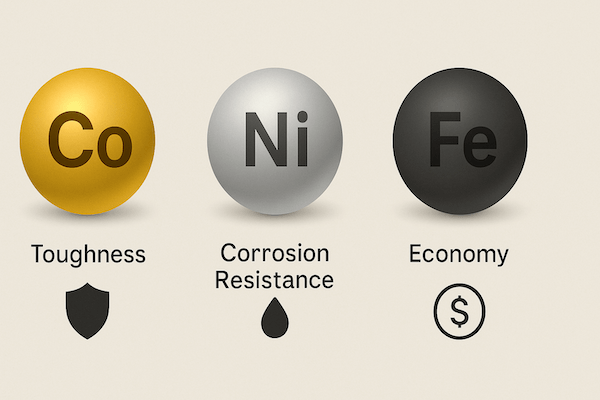

Binder material refers to the metallic phase—usually cobalt (Co) or nickel (Ni)—used to bind tungsten carbide (WC) grains together during sintering. While WC provides extreme hardness and abrasion resistance, the binder acts as the “glue” that holds the grains together and adds toughness to the composite.

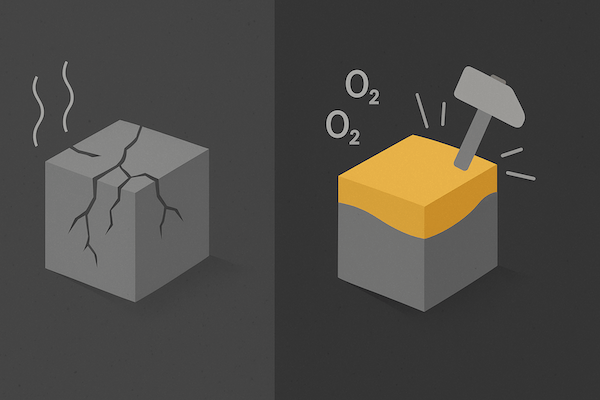

Without the binder, tungsten carbide would be too brittle for practical applications, especially under impact or mechanical stress.

Role of Binder Material in Tungsten Carbide

1. Toughness and Impact Resistance

Tungsten carbide is extremely hard but brittle. The binder provides ductility and fracture toughness, allowing the tool to absorb shock loads without cracking or shattering.

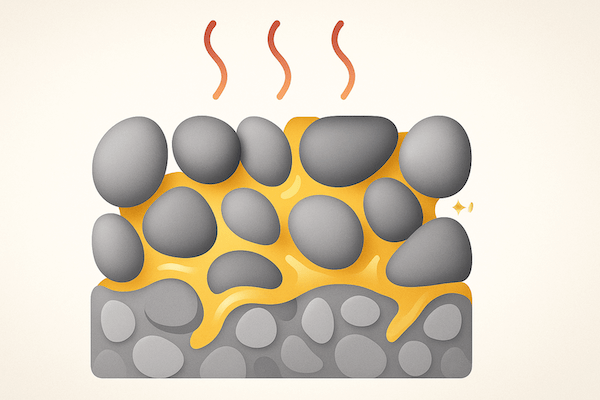

2. Sintering and Densification

During the sintering process, the binder melts (while WC remains solid) and infiltrates the compacted powder, enabling grain-to-grain bonding and the elimination of porosity. This is key to achieving high density and strength in the final product.

3. Thermal and Chemical Performance

The choice of binder affects the tool’s resistance to heat and corrosion. For example:

Cobalt offers good toughness and wear resistance but may oxidize at high temperatures.

Nickel provides better corrosion resistance, making it suitable for chemical and oil & gas environments.

Common Types of Binder Materials

| Binder Type | Characteristics | Applications |

|---|---|---|

| Cobalt (Co) | High toughness, excellent sintering properties | General machining, mining, cutting tools |

| Nickel (Ni) | Better corrosion resistance, lower strength than Co | Oil & gas, chemical processing |

| Iron (Fe) (less common) | Economical, used in specific blends | Limited applications |

In some advanced grades, binder phase modifiers like Cr₃C₂, VC, or TaC are added to:

Refine grain size

Improve oxidation resistance

Inhibit phase growth during sintering

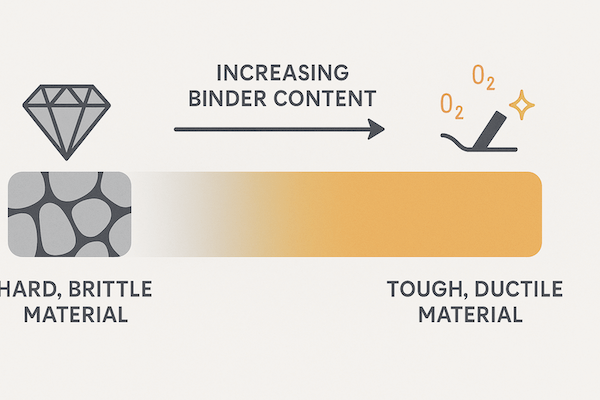

How Binder Content Affects Tool Properties

The binder content, usually ranging from 4% to 25% by weight, significantly affects tool performance:

Lower binder content (4–10%) → Higher hardness, better wear resistance, less toughness

Higher binder content (15–25%) → Increased toughness, suitable for heavy impact applications

Therefore, the binder ratio is carefully selected based on the tool’s intended use. Cutting tools require higher hardness, while drilling or mining tools may prioritize toughness.

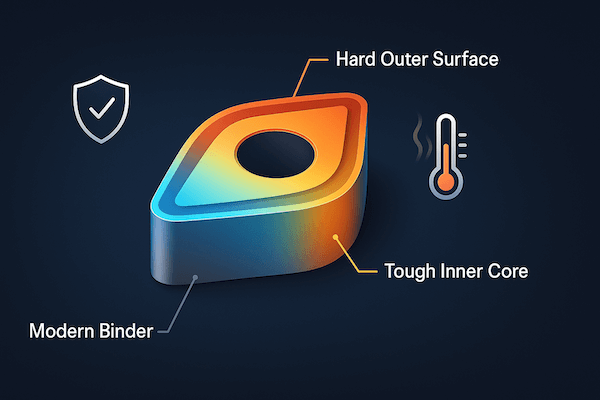

Innovations in Binder Technology

With rising demand for performance in extreme environments, carbide tools manufacturers are developing new binder systems such as:

Binderless WC (ultra-hard, no metallic binder)

Co-Ni-Cr alloy binders for enhanced oxidation resistance

Gradient binder distribution to create tough cores and hard surfaces in one piece

These innovations help address modern challenges like high-speed machining, thermal fatigue, and environmental corrosion.

Conclusion

Binder material is the unsung hero behind the success of tungsten carbide tools. By balancing hardness with toughness, and enabling strong sintered structures, it transforms brittle tungsten carbide into a versatile, high-performance tool material. As binder technology continues to evolve, so too does the capability of cemented carbide in demanding applications across mining, machining, aerospace, and more.