In chemical plants, reactors and agitator shafts operate under extreme conditions. They handle high pressure, corrosive chemicals, and continuous motion.

A single leak can cause costly downtime, product contamination, or even safety hazards. Carbide seal rings have become the preferred choice for protecting these systems.

This article explains why carbide seal rings are essential for chemical reactors and agitator shafts, how they perform under demanding conditions, and what decision-makers should consider when selecting them.

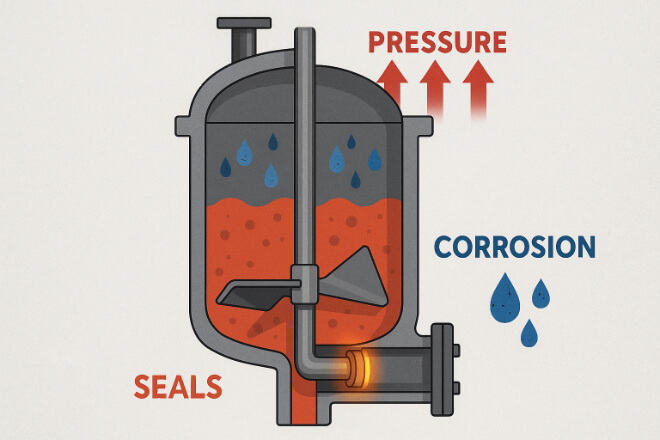

Challenges in Chemical Reactors and Agitators

Corrosive chemicals can quickly damage seals.

High pressures and temperatures stress equipment.

Continuous operation creates wear and friction.

Safety regulations demand reliable sealing to prevent hazardous leaks.

Conventional seal materials like stainless steel or carbon graphite may fail quickly in these conditions. Carbide seal rings offer a better solution.

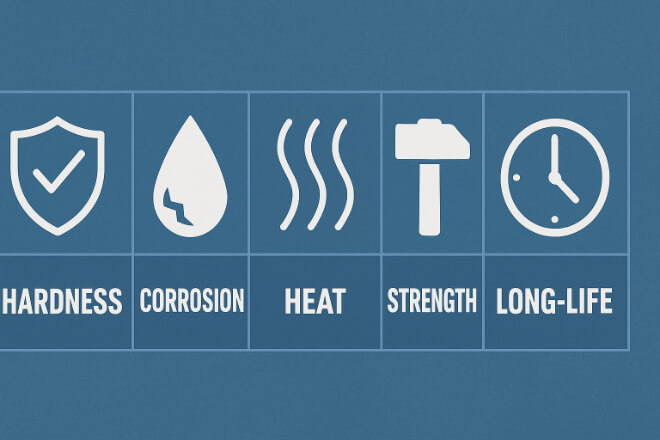

Why Choose Carbide Seal Rings

1). Superior Hardness and Wear Resistance

Carbide is nearly as hard as diamond. It resists scratches and abrasive particles that cause rapid wear in chemical mixing processes.

Nickel-bonded carbide stands up to acids, solvents, and alkalis commonly used in reactors.

3). Strength and Toughness

Cobalt-bonded carbide provides toughness, preventing cracking under high pressure or shock loads on agitator shafts.

4). Thermal Stability

Carbide rings maintain sealing performance even at elevated temperatures found in chemical reactions.

5). Longer Service Life

Fewer replacements mean lower maintenance costs and reduced downtime.

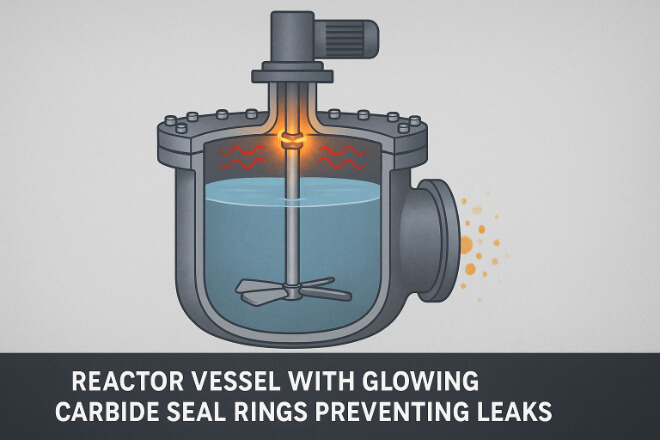

Applications in Chemical Reactors

1). Reactor Seals

Reactors contain highly reactive chemicals. Carbide rings ensure a tight seal, preventing leaks that could contaminate products or harm workers.

2). High-Pressure Reactors

In high-pressure reactions, carbide rings withstand the stress and maintain integrity where softer materials fail.

3). Corrosive Media Reactors

Nickel-bonded carbide seals resist chemical attack in acid or alkali-based processes.

Applications in Agitator Shafts

1). Mixing Tanks and Vessels

Agitator shafts rotate continuously. Carbide seals reduce friction and wear, extending shaft and bearing life.

2). Polymer and Resin Production

In sticky or abrasive media, carbide rings keep a reliable seal, preventing leaks during mixing.

3). Pharmaceutical and Food Processing

Polished carbide rings provide hygienic, leak-free operation in regulated environments.

Benefits for Chemical Plants

| Benefit | Description |

|---|---|

| Leak Prevention | Tight sealing avoids leaks of hazardous chemicals. |

| Longer Service Life | Resists corrosion and wear, reducing replacement frequency. |

| Improved Safety | Reduces risk of chemical spills and worker exposure. |

| Cost Efficiency | Fewer failures mean less downtime and lower maintenance costs. |

| Process Reliability | Stable seals ensure consistent chemical reactions and product quality. |

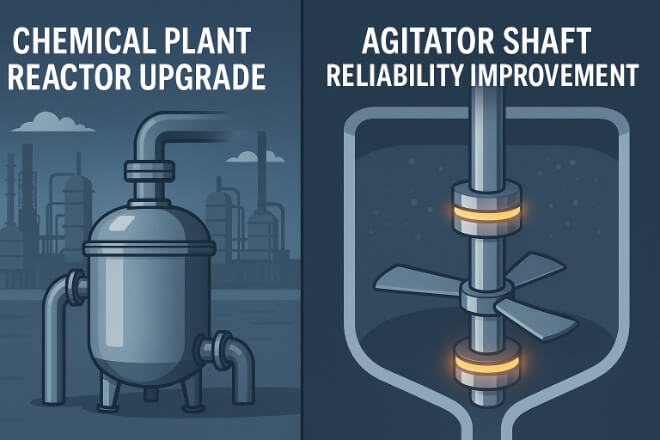

Case Studies

1). Chemical Reactor Upgrade

A chemical plant switched from stainless steel seals to nickel-bonded carbide rings. Result: seal life doubled and unplanned downtime dropped by 40%.

2). Agitator Shaft Reliability

A polymer production facility replaced ceramic seals with carbide rings. Result: improved mixing consistency and reduced maintenance costs.

How to Select the Right Carbide Seal Ring

1). Binder Type

Use nickel-bonded carbide for corrosive chemical environments.

Choose cobalt-bonded carbide for high shock loads and mechanical stress.

2). Surface Finish

Polished carbide surfaces reduce friction and heat in agitator shafts.

3). Operating Conditions

Review pressure, temperature, and chemical compatibility.

4). Supplier Expertise

Work with ISO-certified suppliers experienced in chemical industry applications.

Maintenance and Replacement Strategy

Inspect seals for wear, cracks, or corrosion regularly.

Replace seals proactively to avoid costly shutdowns.

Keep spare carbide rings in inventory for critical equipment.

Recycle worn carbide components to reduce waste and cost.

Cost and ROI Considerations

Upfront Investment: Higher than standard seals.

Savings: Lower failure rates reduce unplanned downtime and repairs.

ROI: Improved safety, consistent product quality, and longer service life justify the cost.

Environmental and Safety Advantages

Carbide seal rings help plants avoid chemical spills that could harm workers or the environment. Reliable sealing supports compliance with safety regulations and environmental standards.

Conclusion

Carbide seal rings are essential for chemical reactors and agitator shafts. Their hardness, corrosion resistance, and durability ensure safe and efficient operation under harsh conditions.

For decision-makers, choosing carbide seal rings means fewer failures, lower costs, and safer workplaces—critical advantages in today’s competitive chemical industry.

If you want to know more details about any company, please feel free to contact us.