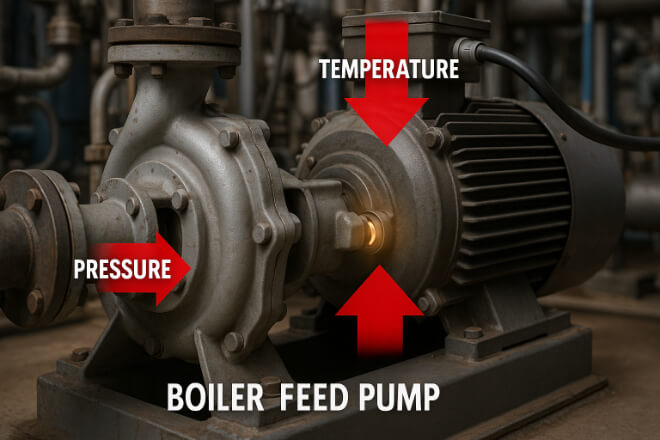

Power plants rely on boiler feed pumps to move water at very high pressure into boilers.

These pumps work under extreme heat, pressure, and continuous operation. Even a small seal failure can stop a unit, cause costly repairs, or reduce power generation efficiency.

Carbide seal rings have become the preferred choice for these pumps. They provide excellent hardness, toughness, and corrosion resistance.

For decision-makers, using carbide seals means fewer shutdowns, safer operations, and better return on investment.

Challenges in Boiler Feed Pump Sealing

High pressure and temperature can deform or damage weak seals.

Continuous operation increases friction and wear.

Water impurities or chemical additives can corrode metal components.

Unexpected leaks can lead to boiler trips or turbine damage.

Standard materials like stainless steel or carbon graphite often fail quickly in these conditions.

Carbide seal rings are engineered to withstand such harsh environments.

Why Carbide Seal Rings Are Ideal for Power Plants

1). Extreme Hardness

Carbide is nearly as hard as diamond, resisting scratches and abrasive particles in feedwater.

2). Strength and Toughness

Cobalt-bonded carbide survives pressure fluctuations and vibration common in boiler feed pumps.

Nickel-bonded carbide resists attack from water treatment chemicals or dissolved oxygen.

4). Thermal Stability

Carbide maintains its shape and performance under the high temperatures of boiler feed systems.

5). Long Service Life

Fewer replacements reduce downtime and maintenance costs.

Applications in Power Plant Systems

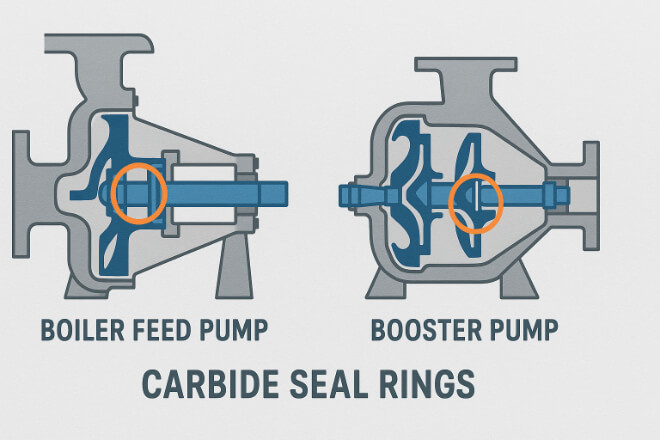

Boiler Feed Pumps

Primary pumps pushing water into boilers use carbide seals to maintain reliability.

Booster Pumps

Booster pumps feeding the main boiler pumps benefit from carbide’s durability.

Auxiliary Water Systems

Carbide rings in auxiliary pumps improve plant-wide sealing performance.

Benefits for Power Generation Operations

| Benefit | Description |

|---|---|

| Extended Service Life | Resists wear and corrosion, reducing frequency of replacements. |

| Reduced Downtime | Fewer failures mean pumps stay operational and power output remains stable. |

| Improved Safety | Reliable sealing prevents leaks that could damage turbines or boilers. |

| Lower Maintenance Costs | Less frequent part replacement reduces labor and spare part expenses. |

| Better Efficiency | Smooth, polished carbide reduces friction, improving pump performance. |

Real-World Examples

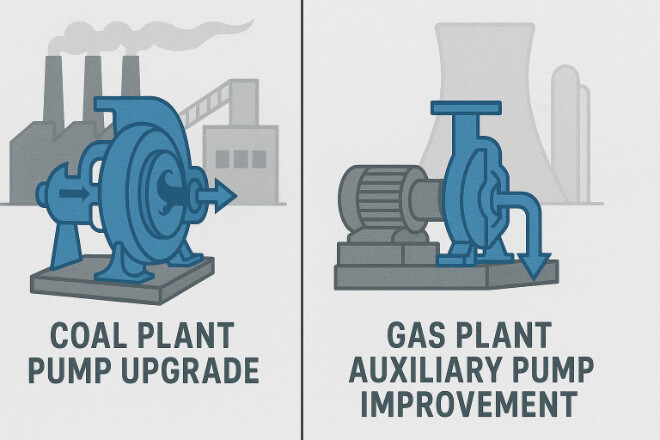

Coal-Fired Power Plant Upgrade

A coal plant replaced stainless steel seals with nickel-bonded carbide rings in its boiler feed pumps.

Result: seal life increased by 60%, and unplanned outages dropped significantly.

Combined Cycle Gas Plant Improvement

A gas-fired plant upgraded auxiliary boiler feed pumps with carbide seals.

Result: lower maintenance costs and more stable power output during peak demand.

How to Select the Right Carbide Seal Ring

1). Binder Choice

Nickel-bonded carbide for corrosion resistance in treated water.

Cobalt-bonded carbide for shock loads and pressure changes.

2). Surface Finish

Polished carbide reduces friction, heat, and wear.

3). Operating Conditions

Evaluate temperature, pressure, and water chemistry for best grade selection.

4). Supplier Experience

Choose ISO-certified suppliers with proven power industry expertise.

Maintenance and Replacement Strategy

Inspect seals during scheduled outages or maintenance cycles.

Replace worn rings before leaks or efficiency loss occur.

Stock spare carbide seals to minimize downtime.

Recycle used carbide components to reduce environmental impact and costs.

Cost and ROI Considerations

Initial Cost: Carbide seals are more expensive upfront.

Savings: Fewer failures reduce emergency repairs and unplanned outages.

ROI: Longer service life, improved safety, and efficiency gains justify the investment.

Environmental and Safety Advantages

Reliable sealing prevents water leaks that could damage sensitive equipment or cause unsafe conditions.

Stable pump performance also supports efficient energy use, reducing overall environmental impact.

Conclusion

Carbide seal rings are the smart choice for power plant boiler feed pumps. Their hardness, corrosion resistance, and toughness ensure pumps remain reliable under extreme pressure and temperature.

For decision-makers, investing in carbide seals improves safety, reduces maintenance costs, and enhances power generation efficiency—critical advantages in competitive energy markets.

If you want to know more details about any company, please feel free to contact us.