Selecting the right seal ring material for chemical processing, pharmaceutical, or industrial fluid systems is never simple.

In harsh chemical media, the choice often narrows to carbide seal rings or ceramic rings.

Both materials offer corrosion resistance and dimensional stability, yet their behaviors under stress, temperature, and chemical exposure differ significantly.

For decision-makers managing pumps, compressors, or agitators in corrosive environments, this guide compares carbide.

And ceramic seal rings across critical parameters such as chemical resistance, mechanical strength, and tribological performance, supported by a clear selection matrix for practical reference.

Understanding Harsh Chemical Media

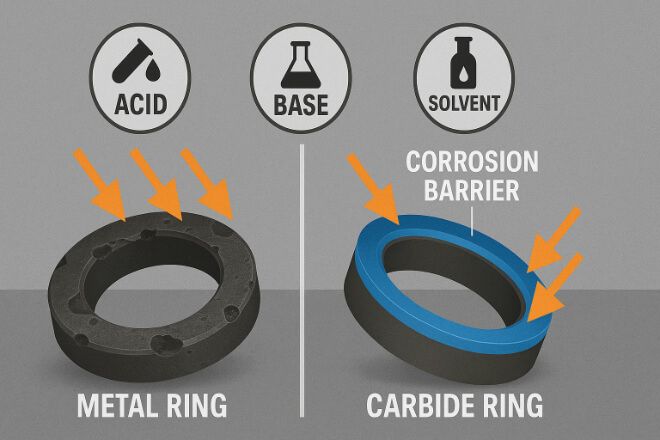

“Harsh chemical media” refers to liquids containing acids, bases, oxidizers, or solvents that can degrade conventional materials. Examples include:

Hydrochloric acid, sulfuric acid, and caustic soda

Ammonia, chlorinated hydrocarbons, and strong oxidants

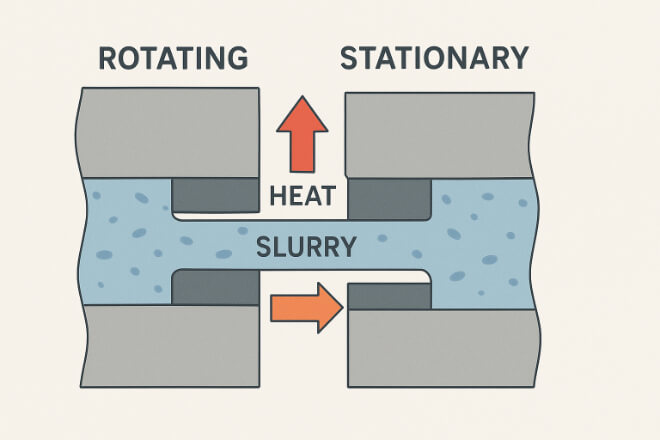

Abrasive slurries containing reactive chemicals

Such environments demand seal faces that can withstand chemical attack, thermal cycling, and mechanical load simultaneously.

Carbide Seal Rings: Metal Toughness Meets Chemical Stability

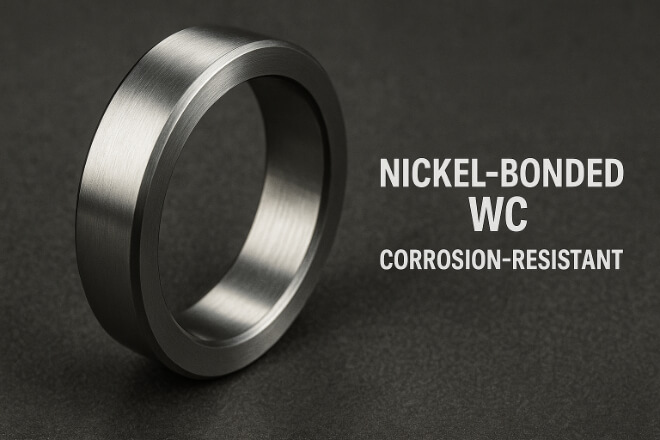

Carbide seal rings, typically tungsten carbide (WC) with a nickel or cobalt binder, are engineered for both toughness and wear resistance.

1). Key Strengths

High hardness: Excellent resistance to abrasive particles.

Superior toughness: Maintains integrity under pressure and impact.

Good heat transfer: Prevents hot spots and thermal cracking.

Customizable grades: Nickel-bonded for corrosion, cobalt-bonded for shock loads.

2). Chemical Resistance Profile

Nickel-bonded grades of WC perform well against most neutral and mildly acidic chemicals but may degrade in strong oxidizing acids like nitric acid.

In contrast, ceramic materials can survive in more oxidizing conditions but are less impact-resistant.

3). Common Industrial Uses

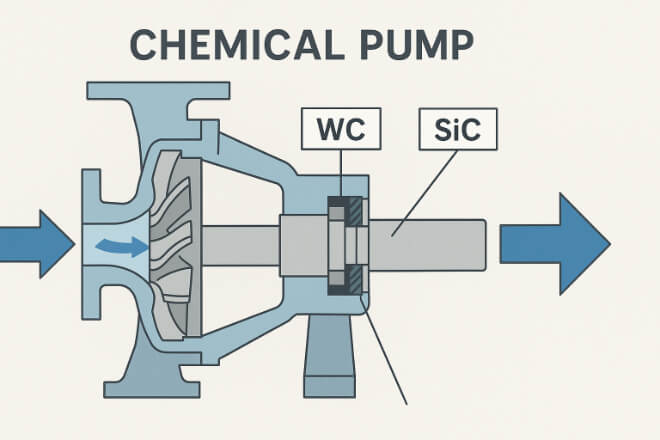

Chemical pumps handling acids and slurries.

Mixers and agitators in refinery and fertilizer plants.

Compressors for corrosive gases.

Ceramic Seal Rings: Chemically Inert but Brittle

Ceramic rings, often made from alumina oxide (Al₂O₃) or silicon carbide (SiC) ceramics, are favored for their chemical inertness and low friction.

1). Key Strengths

Excellent chemical resistance: Unaffected by most acids, alkalis, and solvents.

Low friction coefficient: Reduces energy loss during operation.

Corrosion-proof and non-reactive: Ideal for ultra-pure applications.

2). Limitations

Brittleness: Sensitive to shock, vibration, and pressure pulsations.

Lower thermal conductivity: Retains heat longer than WC.

Difficult repairability: Once cracked, replacement is necessary.

3). Common Industrial Uses

Semiconductor wet benches.

Pharmaceutical reactors and high-purity systems.

Chemical transfer pumps with stable, low-load operation.

Comparative Selection Matrix

| Property | Carbide Seal Rings (WC) | Ceramic Seal Rings (Al₂O₃ / SiC) |

|---|---|---|

| Hardness | Very High (Mohs 8.5–9) | Extremely High (Mohs 9–9.5) |

| Toughness | Excellent (impact-resistant) | Low (brittle under load) |

| Chemical Resistance | Good (nickel-binder improves performance) | Excellent (chemically inert) |

| Thermal Conductivity | High (good heat dissipation) | Moderate (retains surface heat) |

| Corrosion Resistance | Very Good (depends on binder) | Outstanding (immune to most chemicals) |

| Shock Resistance | Excellent | Poor |

| Best Applications | High-pressure, slurry, or mixed chemical flow | Ultra-clean, low-load, or highly corrosive systems |

Chemical Compatibility and Material Pairing

For seals exposed to mixed acids or oxidizing agents, both material chemistry and binder choice matter:

Nickel-bonded carbide resists most acids better than cobalt-bonded versions.

Alumina ceramics handle oxidizing media but can crack under vibration.

Silicon carbide ceramics balance hardness and corrosion resistance but remain brittle under impact.

Pairing combinations such as WC vs SiC or SiC vs carbon graphite are often used to optimize both sealing and lubrication.

Tribology and Friction Behavior

In chemical service, friction determines face temperature and seal wear rate.

Ceramic rings offer a lower friction coefficient (~0.15) in clean fluids.

Carbide rings typically show ~0.20–0.25 but remain more stable under particle impact.

Dry running: Carbide faces survive longer before failure.

The key is to balance frictional heat and mechanical resilience depending on system load.

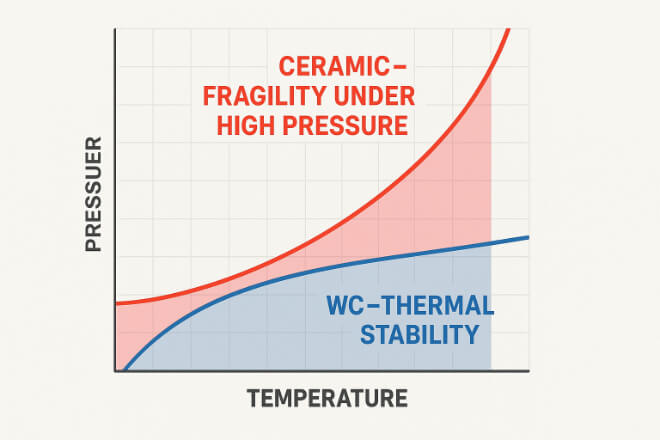

Temperature and Pressure Considerations

Carbide rings withstand pressures up to 100 bar and temperatures up to 650°C.

Ceramic rings tolerate higher temperatures (up to 1000°C) but only in stable, low-shock conditions.

For thermal cycling environments, carbides provide better structural reliability.

Cost and Maintenance Comparison

| Aspect | Carbide Seal Rings | Ceramic Seal Rings |

|---|---|---|

| Initial Cost | Moderate to High | Low to Moderate |

| Repairability | Can be re-lapped and reused | Usually requires replacement |

| Operational Life in Abrasive Media | Longer (3× average) | Shorter (brittle failure risk) |

Industry Application Examples

Chemical plants: Carbide for strong acids; ceramics for oxidizing media.

Pharmaceutical equipment: Ceramics for purity and corrosion-free contact.

Wastewater treatment: Carbide for solids-laden and variable pH conditions.

Marine pumps: WC provides reliability under vibration and saltwater corrosion.

Decision Framework: Choosing Between Carbide and Ceramic

If process fluid is clean but corrosive → choose ceramics.

If the environment includes solids, vibration, or shock → choose carbides.

If the system cycles between hot and cold → carbide handles stress better.

If purity is critical (e.g., food or semiconductor) → ceramics ensure zero contamination.

Conclusion

In harsh chemical media, both carbide and ceramic seal rings have distinct advantages:

Carbide: Superior toughness, thermal control, and resistance to particle damage.

Ceramic: Outstanding chemical inertness and smooth, low-friction operation.

For most industrial chemical systems, nickel-bonded tungsten carbide provides a balanced solution that combines mechanical stability with corrosion protection.

While ceramics remain the best option where purity and zero metallic contamination are mandatory.

If you want to know more details about any company, please feel free to contact us.