The pulp and paper industry is one of the most demanding industrial environments.

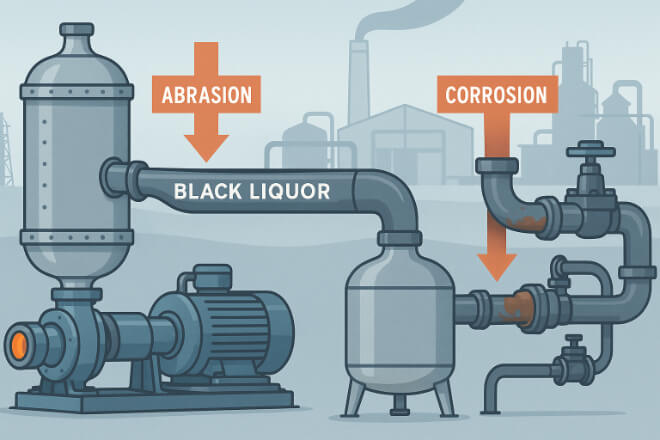

Pumps, mixers, and pipelines in these plants handle abrasive pulp fibers, corrosive chemicals, and high-pressure black liquor.

Even small leaks can disrupt production, damage equipment, or cause environmental harm.

Carbide seal rings have become the go-to solution for this sector. They provide excellent hardness, corrosion resistance, and long service life.

For decision-makers, investing in carbide seals means fewer breakdowns, safer operations, and reduced costs.

Challenges in Pulp, Paper, and Black Liquor Services

Abrasive pulp fibers quickly wear down standard seals.

Black liquor, a byproduct of pulping, is highly alkaline and corrosive.

High temperatures in chemical recovery boilers and evaporators stress equipment.

Continuous operation makes downtime expensive and disruptive.

Stainless steel or carbon graphite seals are often not strong enough for these conditions. Carbide seal rings offer the strength and reliability needed.

Why Carbide Seal Rings Are the Best Choice

1). Hardness and Wear Resistance

Carbide is almost as hard as diamond. It resists scratches and wear caused by pulp fibers and solid particles in black liquor.

Nickel-bonded carbide is highly resistant to alkaline and chemical attack, making it perfect for black liquor systems.

3). Strength and Shock Resistance

Cobalt-bonded carbide handles pressure changes and mechanical shock loads in mixers and pumps.

4). Thermal Stability

Carbide rings maintain performance even at the high temperatures found in bleaching and recovery processes.

5). Longer Service Life

Reduced wear and corrosion mean fewer replacements and lower maintenance costs.

Applications in Pulp and Paper Processing

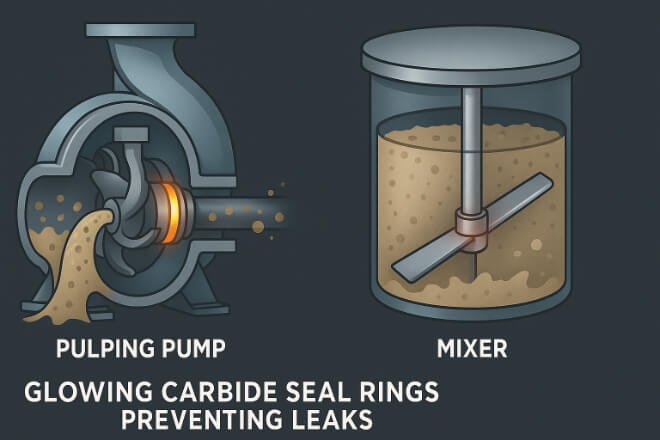

1). Pulping Pumps

Carbide seal rings prevent leaks in pumps transferring abrasive pulp mixtures.

2). Refiners and Mixers

Continuous mixing and refining require seals that reduce friction and resist wear.

3). Bleaching Systems

In corrosive bleaching chemicals, carbide rings maintain a reliable seal.

Applications in Black Liquor Services

1). Black Liquor Evaporators

Carbide seals prevent leaks in evaporators handling concentrated, corrosive black liquor.

2). Recovery Boilers

Seal rings withstand the combination of high heat and chemical attack.

3). Chemical Recovery Circuits

Durable carbide rings improve reliability in systems recycling black liquor.

Benefits for the Pulp and Paper Industry

| Benefit | Description |

|---|---|

| Extended Service Life | Resists abrasive pulp and corrosive liquor, reducing replacements. |

| Reduced Downtime | Fewer seal failures keep equipment running and production steady. |

| Improved Safety | Prevents leaks of hot, caustic black liquor that could harm workers. |

| Cost Efficiency | Less maintenance and fewer replacements lower total cost of ownership. |

| Process Reliability | Stable sealing supports consistent pulp and paper production quality. |

Case Studies

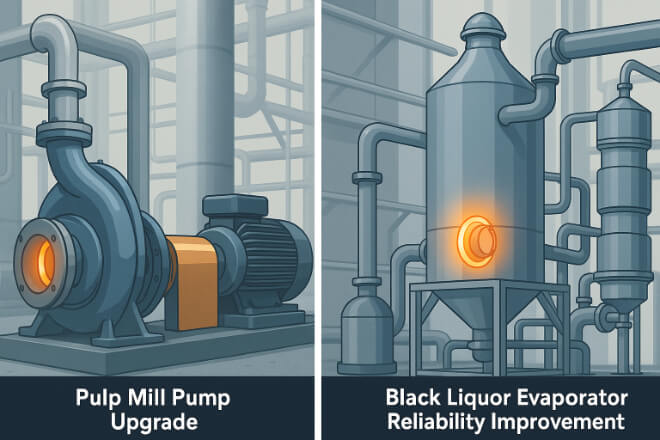

1). Pulp Mill Pump Upgrade

A pulp mill replaced stainless steel seals with nickel-bonded carbide rings. Result: seal life doubled and unplanned maintenance dropped by 40%.

2). Black Liquor Evaporator Reliability

A paper plant used carbide rings in black liquor evaporators. Result: fewer leaks, improved environmental compliance, and lower operating costs.

How to Select the Right Carbide Seal Ring

1). Binder Type

Nickel-bonded carbide for corrosive black liquor and bleaching chemicals.

Cobalt-bonded carbide for shock loads in agitators and pulping pumps.

2). Surface Finish

Polished carbide surfaces reduce friction and wear in rotating equipment.

3). Operating Conditions

Consider temperature, pressure, and chemical exposure when selecting grade.

4). Supplier Expertise

Choose ISO-certified suppliers with experience in pulp and paper applications.

Maintenance and Replacement Strategy

Inspect seals for cracks, grooves, or corrosion during planned shutdowns.

Replace worn rings before leaks occur to avoid production loss.

Keep spare carbide seals in stock for critical pumps and mixers.

Recycle used carbide components to reduce cost and environmental impact.

Cost and ROI Considerations

Initial Cost: Higher than standard seals.

Savings: Reduced leaks and downtime improve profitability.

ROI: Longer service life and improved reliability justify the investment.

Environmental and Safety Advantages

Preventing black liquor leaks protects rivers, groundwater, and plant workers. Carbide seals help plants comply with environmental regulations and maintain a safe workplace.

Conclusion

Carbide seal rings are essential for pulp, paper, and black liquor services. Their hardness, corrosion resistance, and durability make them the best choice for challenging environments.

For decision-makers, carbide seals ensure fewer breakdowns, lower maintenance costs, improved safety, and stable production quality—key factors in staying competitive in the pulp and paper industry.

If you want to know more details about any company, please feel free to contact us.