Tungsten Carbide Valve Components

Retop manufactures precision tungsten carbide valve components including seats, discs, cages, and trims—engineered for severe-service valves in oil & gas, chemical processing, and high-abrasion applications.

- Extreme wear and erosion resistance

- Reliable performance in high-pressure fluids

- Custom designs for valve seats, trims, cages

- Excellent chemical and thermal stability

Product Description

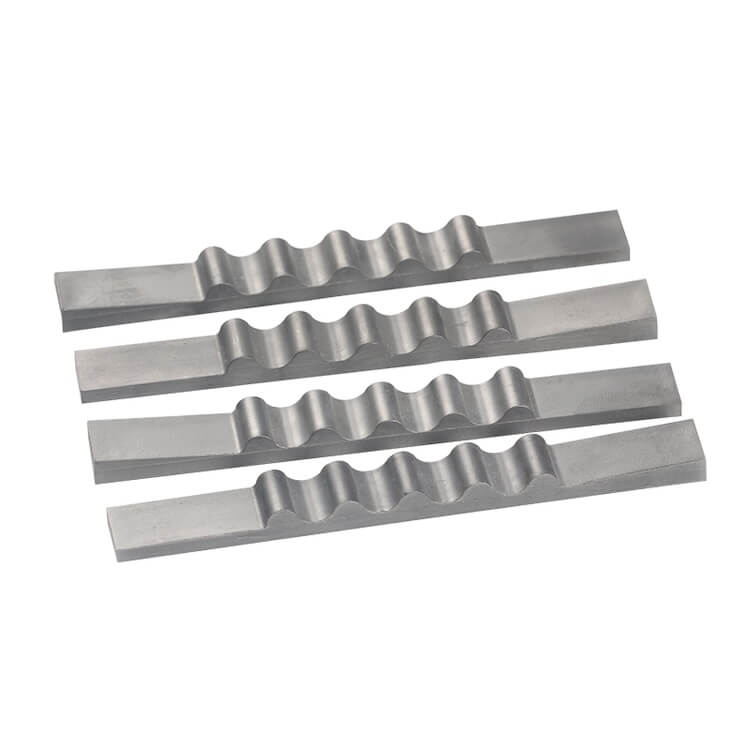

Tungsten carbide valve components are critical parts used in severe-service control and isolation valves, where fluid media involves abrasive particles, corrosive chemicals, or high-temperature gases. Retop produces a full range of valve parts such as carbide valve seats, plugs, trims, cages, and discs, all made from cemented tungsten carbide (WC-Co or WC-Ni) with precision grinding, lapping, and coating options to improve sealing, longevity, and resistance to erosion.

These components are essential in choke valves, globe valves, safety relief valves, and control valves operating in oilfield drilling, petrochemical pipelines, high-pressure gas injection systems, power plants, and chemical reactors. Carbide valve parts are also widely used in slurry pipelines, desalination plants, and mining slurry pumps—where traditional metal parts fail prematurely due to erosion, corrosion, or thermal cycling.

Features

Superior Hardness & Erosion Resistance

Handles sand, gas, slurry, and aggressive media under pressure without deformation.Precision Sealing Surfaces

Flatness tolerance < 0.001 mm ensures zero-leak sealing in high-cycle valves.Custom Fit for OEM or API Standards

Supports designs based on API 6A, 6D, and customer-specific geometries.Optional Coatings

Apply TiN, TiAlN, or diamond-like coatings for extended corrosion and wear resistance.Machined to Exact Tolerances

All parts undergo CNC, ID/OD grinding, and ultrasonic inspection.

Specifications

| Specification | Value |

|---|---|

| Material | Tungsten Carbide (WC+Co / WC+Ni) |

| Hardness (HRA) | 89 – 94 |

| Surface Flatness | ≤ 0.001 mm (lapping available) |

| Applications | Oil & Gas, Chemical, Power, Mining |

| Working Pressure | Up to 15,000 psi |

| Coating Options | None / TiN / TiAlN / DLC |

| Standards | API 6A, 6D or customer drawings |

Why Choose Retop as Your Supplier?

Retop delivers carbide valve components trusted by leading OEMs and energy providers worldwide. With over 14 years of experience in producing high-performance carbide wear parts, we ensure tight dimensional tolerances, zero-defect surface finishing, and rapid prototyping capabilities. Our parts are backed by ISO 9001-compliant quality systems, in-house sintering, and advanced CNC machining to meet even the most complex valve requirements under extreme service conditions.