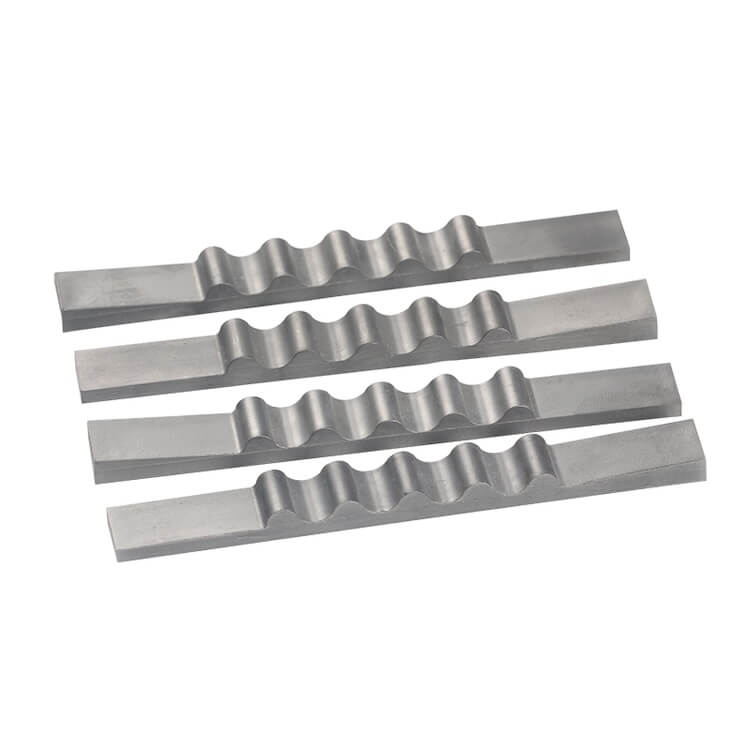

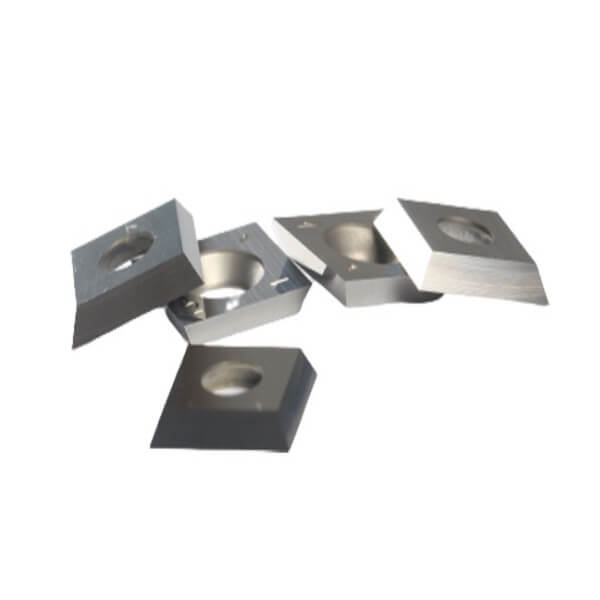

Carbide Wear Plates & Strips

Retop manufactures high-performance tungsten carbide wear plates and strips designed to withstand heavy impact, friction, and abrasive media in mining, construction, and industrial processing environments.

- Outlast steel 10x in abrasive wear

- Precision ground surfaces for easy fitting

- Customizable dimensions and hole patterns

- Withstands high temperatures and impact loads

Product Description

Carbide wear plates and strips are flat tungsten carbide components engineered to protect critical surfaces from abrasion, erosion, and high-impact wear. Manufactured from cemented carbide (WC-Co) through precision sintering and grinding, these components offer exceptional hardness (up to HRA 92.5) and long-term dimensional stability. Retop provides both standard and custom-shaped wear plates, including rectangular, stepped, notched, and slotted profiles.

Tungsten carbide wear strips and plates are widely used in mining screens, concrete mixers, aggregate hoppers, coal chutes, feed blades, forming dies, and wear liners in crushers and presses. They are especially beneficial in industries such as cement, mining, road milling, agriculture, and powder metallurgy, where surface degradation leads to frequent downtime and high maintenance costs.

Features

Extreme Surface Hardness

Maintains HRA 89–92.5 even in harsh impact and sliding wear conditions.Multiple Shape Options

Flat, stepped, curved, or slotted strips available to fit wear zones precisely.Machinable Mounting Options

Drilled holes, countersinks, or slots for secure installation and easy replacement.Corrosion and Thermal Resistance

Ideal for acidic, high-temperature, or chemically aggressive environments.Custom Thickness and Surface Finish

Available in thicknesses from 1 mm to 25 mm with mirror-polished or matte finishes.

Specifications

| Specification | Value |

|---|---|

| Material | Tungsten Carbide (WC+Co) |

| Hardness (HRA) | 89 – 92.5 |

| Thickness Range | 1 mm – 25 mm |

| Width / Length | Customized up to 300 mm × 500 mm |

| Surface Finish | Ground / Lapped / Polished |

| Mounting Options | Plain, Slotted, or Drilled |

| Application Fields | Mining, Mixing, Pressing, Forming |

Why Choose Retop as Your Supplier?

Retop offers carbide wear plates and strips backed by over 14 years of expertise in tungsten carbide manufacturing. Our factory utilizes advanced powder metallurgy, HIP sintering, and CNC grinding to deliver parts with consistent hardness, tight tolerance, and excellent flatness. Whether you need custom hole patterns, stepped edges, or complex profiles, Retop delivers with fast lead times, ISO-certified quality, and technical support to ensure your equipment stays protected in the most demanding environments.