In industries such as oil and gas, chemical processing, marine, and power generation, sealing systems face harsh and corrosive environments.

Equipment often operates under high pressure, heat, and exposure to aggressive fluids.

If seals fail, the result is leakage, downtime, and expensive repairs. For this reason, many companies rely on tungsten carbide seal rings.

This article explores why tungsten carbide is valued for its chemical resistance, how it performs in harsh environments, and what decision-makers should consider when choosing seal rings.

What Makes a Seal Ring Chemically Resistant?

A chemically resistant seal ring is one that can withstand attack from corrosive fluids without losing strength or shape.

In harsh environments, seals must resist:

Acids and alkalis

Seawater and salt solutions

Hydrocarbons such as oil and gas

Aggressive chemical slurries

Without resistance, materials can corrode, swell, or crack, leading to early failure.

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a hard compound of tungsten and carbon, usually bonded with cobalt or nickel. Its main properties for chemical resistance include:

High density → Limits fluid penetration.

Corrosion resistance → Especially with nickel binder in chemical or marine use.

Thermal stability → Maintains resistance under hot conditions.

Wear resistance → Protects against abrasive fluids with particles.

These features make tungsten carbide suitable for long-term sealing in chemical-rich environments.

Nickel-Bonded vs Cobalt-Bonded Tungsten Carbide

The binder material affects chemical resistance:

1). Cobalt-bonded tungsten carbide

High toughness and shock resistance.

Moderate corrosion resistance, weaker against strong acids.

Best for oil and gas pumps under shock loads.

2). Nickel-bonded tungsten carbide

Excellent corrosion resistance in seawater and chemicals.

Less tough than cobalt-bonded.

Best for marine pumps and chemical processing plants.

Decision-makers must choose the grade that matches the operating fluid.

Performance in Harsh Environments

1). Oil and Gas

Seal rings resist hydrocarbons, abrasive fluids, and pressure changes, reducing downtime in drilling and refinery pumps.

2). Chemical Plants

Nickel-bonded tungsten carbide seals resist acids, alkalis, and solvents, ensuring longer service life.

3). Marine Systems

Exposure to seawater leads to corrosion in weaker materials. Tungsten carbide seals maintain performance in ballast and cooling pumps.

4). Power Generation

High-temperature fluids and cooling water systems require both thermal stability and corrosion resistance, which tungsten carbide provides.

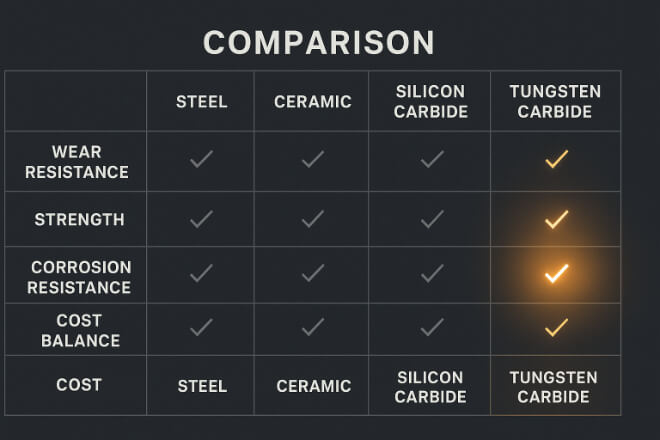

Advantages Over Other Seal Materials

Steel seals → Corrode quickly in acids and seawater.

Ceramic seals → Resist chemicals but brittle under shock.

Silicon carbide → Corrosion resistant but more fragile under impact.

Tungsten carbide → Offers the best balance of toughness, wear resistance, and chemical stability.

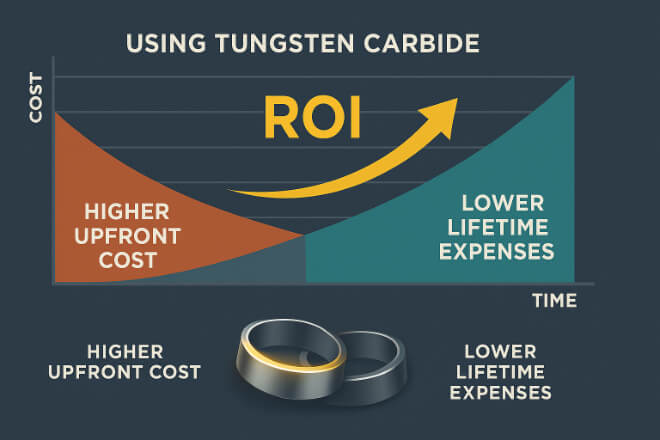

Cost vs Long-Term Value

Tungsten carbide seal rings are more expensive upfront than steel or rubber seals. But in harsh environments, their longer life means:

Fewer replacements

Lower maintenance costs

Reduced downtime

Higher return on investment

For companies where downtime costs thousands per hour, tungsten carbide’s value is clear.

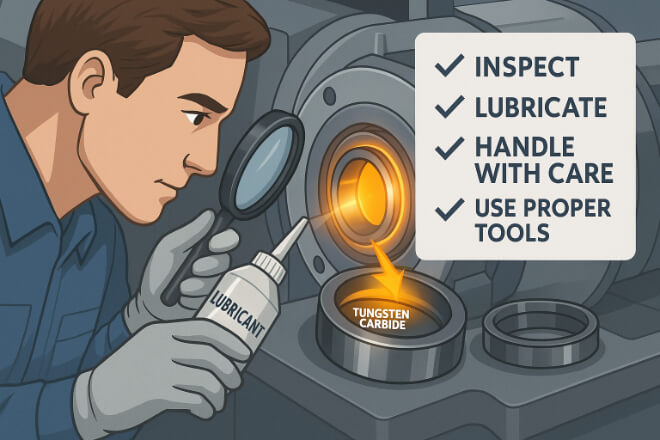

Best Practices to Maximize Chemical Resistance

To improve seal life in harsh environments:

Select the right binder → Nickel-bonded for corrosive fluids, cobalt-bonded for high shock.

Ensure correct installation → Avoid scratches that invite corrosion.

Use proper lubrication → Prevents overheating and chemical attack.

Regular inspections → Catch early signs of wear or corrosion.

Sustainability and Recycling

Another advantage is recyclability. Worn tungsten carbide seal rings can be collected and processed into new materials. Recycling reduces demand for raw tungsten and lowers environmental impact.

Key Takeaways for Decision-Makers

Tungsten carbide seal rings provide strong chemical resistance in harsh environments.

Nickel-bonded grades are best for marine and chemical industries.

Cobalt-bonded grades are better in high-shock conditions.

Long-term ROI makes tungsten carbide the smarter investment.

Recycling adds sustainability value.

Conclusion

For industries facing harsh chemical environments, tungsten carbide seal rings are a proven solution.

They resist corrosion, wear, and heat better than most alternatives, helping mechanical seals perform reliably.

For decision-makers, tungsten carbide is not just a sealing material—it is a strategic choice for long-term efficiency, reliability, and sustainability.

If you want to know more details about any company, please feel free to contact us.