In modern industries, tungsten carbide balls are widely used in bearings, valves, pumps, grinding, and precision equipment. Their natural hardness and wear resistance already make them strong performers.

But in high-stress environments, coatings and surface treatments take carbide ball performance to the next level.

This article explores how coatings improve performance, which coating types are most effective.

And why decision-makers in industries like oil & gas, mining, aerospace, and manufacturing should consider surface treatments for better ROI.

Why Coatings Matter for Carbide Balls

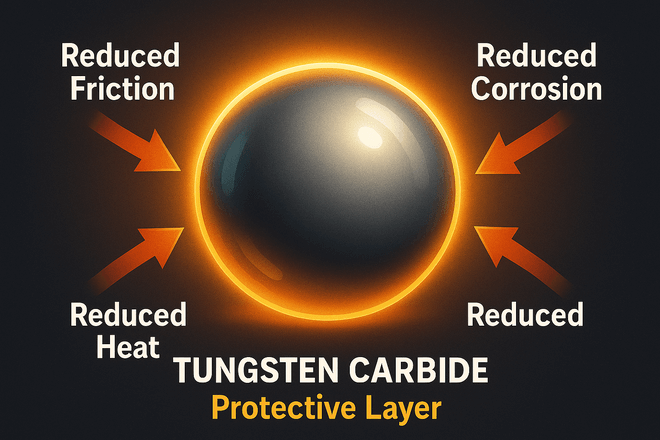

Even though tungsten carbide balls are much harder and more durable than steel, they still face challenges such as high friction, extreme heat, and corrosion in harsh environments.

Coatings act as a protective layer that reduces these risks.

Key reasons coatings matter:

They extend service life by reducing wear and tear.

They improve resistance to oxidation, corrosion, and chemical attack.

They help carbide balls perform at higher speeds and loads.

They minimize downtime by preventing premature failure.

For industries where downtime costs thousands of dollars per hour, coatings are not a luxury—they are a strategic investment.

Popular Coating Options for Carbide Balls

Different coatings work for different applications. Choosing the right one depends on the environment and load conditions.

| Coating Type | Main Benefits | Best Applications |

|---|---|---|

| TiN (Titanium Nitride) | Wear resistance, reduced friction, golden finish | Bearings, mechanical valves, general machining |

| TiAlN (Titanium Aluminum Nitride) | High heat resistance, longer tool life | High-speed applications, aerospace, metal cutting |

| DLC (Diamond-Like Carbon) | Ultra-low friction, chemical resistance | Pumps, chemical valves, automotive parts |

| CVD Diamond | Extreme hardness, top wear protection | Grinding media, semiconductor, high-abrasion use |

This variety allows decision-makers to select coatings tailored to specific stress conditions.

Surface Treatments Beyond Coatings

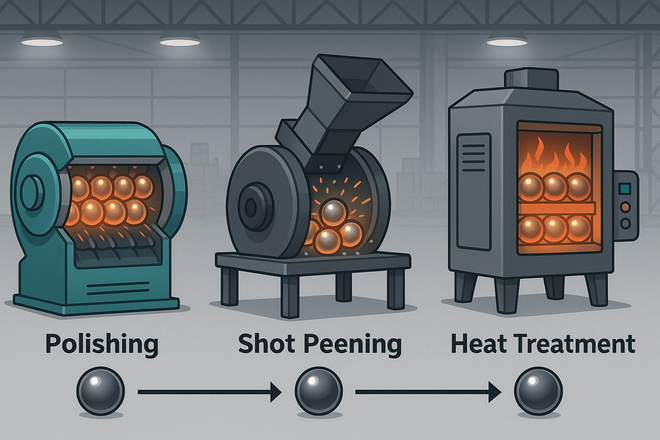

Apart from coatings, surface treatments enhance the strength and reliability of carbide balls:

Polishing: Reduces surface roughness, lowers friction, and prevents wear.

Shot Peening: Adds compressive stress to improve fatigue resistance.

Heat Treatment: Enhances toughness and improves hardness balance.

These treatments often work together with coatings, creating a layered defense system against wear and corrosion.

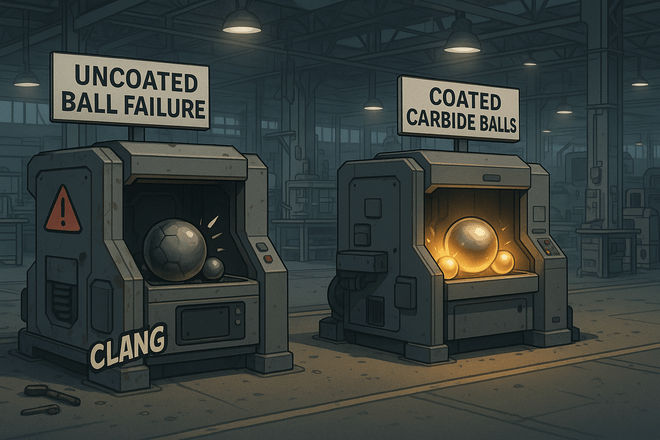

The Role of Coatings in Reducing Downtime

Unplanned downtime is a nightmare in production. Coated carbide balls reduce the risk of sudden failures, making them more reliable than uncoated ones.

For example:

In oil & gas valves, coated carbide balls resist corrosive fluids longer, preventing leaks and shutdowns.

In aerospace ball screws, coatings reduce heat buildup and ensure accuracy.

In mining equipment, coated grinding media lasts longer, lowering replacement frequency.

By minimizing breakdowns, coatings help companies save costs and meet production deadlines.

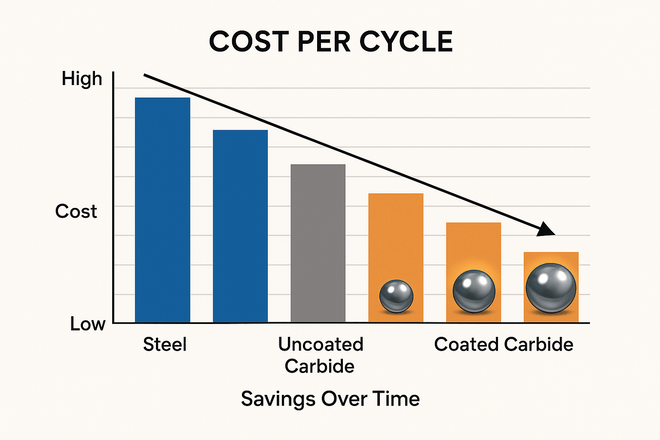

Long-Term ROI of Coated Carbide Balls

While coatings add upfront cost, the return on investment (ROI) is higher in the long run:

Lower replacement frequency = reduced maintenance cost

Longer tool life = fewer disruptions in production

Better performance = higher output quality

Decision-makers should look at cost per cycle or cost per operating hour, not just purchase price.

Coated carbide balls nearly always win when ROI is calculated this way.

Choosing the Right Coating Partner

Not all coatings are equal. Decision-makers should choose suppliers who:

Offer multiple coating options (PVD, CVD, DLC, etc.).

Have proven testing and quality control.

Provide technical guidance on the right coating for each environment.

This ensures you get custom solutions, not just catalog products.

Final Thoughts

Tungsten carbide balls are already leaders in strength and durability. But coatings and surface treatments make them perform better, last longer, and save more money over time.

For industries where every minute of uptime counts, coatings are the difference between average and exceptional performance.

By investing in the right coatings, companies reduce downtime, increase ROI, and ensure reliable operations across demanding applications.

If you want to know more details about any company, please feel free to contact us.